The stick and boom of the excavator are the "arms" of the construction machine. Whether it is used for loading, leveling slopes or digging trenches, any operation is inseparable from the precise tacit cooperation of them. In other words, if they fail, the machine will not work normally!

As the failure problems of the excavator sticks and booms are more complicated, and many machine owners are not good at troubleshooting them, once the failure occurs, they do not know what to do. Today let us take a look at it together. How should we solve the problem of speed drop and slow action of the excavator arm retraction!

1. Failure Phenomenon of Speed Drop and Slow Action of Excavator Arm Retraction

The DOOSAN excavator owner in this study case is typical of boldness and carefulness. A few days ago, when the owner was digging the canal, he had already felt that the excavator stick had a significant speed drop when doing the retraction action. At the same time, he could also clearly feel that the movement became slow. The owner immediately communicated with the engineering party and shut down the machine for maintenance.

After the maintenance engineer arrived at the scene, he found that the situation was indeed consistent with the owner's description, and when the excavator did other actions, it had enough strength and had no speed drop or slow movement problem.

Based on the fault phenomenon, the maintenance engineer made the following analysis, and let us see it together.

2. Cause Analysis of Excavator Arm Retracting Slowly

1. The most common reason is the jamming and wear of the main valve core of the excavator stick, which is also the first point for many maintenance engineers to check.

2. The overload relief valve of the excavator stick works abnormally. The probability that the valve core has problems is high, so it is also the focus of troubleshooting.

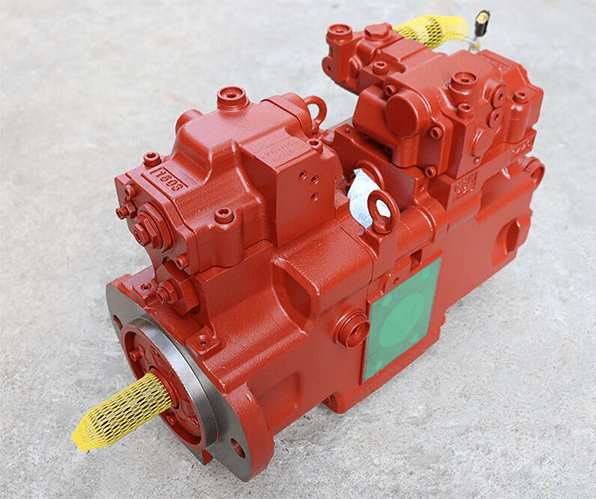

3. The main pump and regulator work abnormally.

4. The inside of the excavator stick holding valve is severely worn and stuck. In a considerable number of cases, the abnormal movement of the stick is due to problems with the holding valve.

3. Troubleshooting Excavator Arm Retracting Slowly

After reviewing the fault phenomenon, the machine only had an obvious speed drop when the arm was retracting, so the maintenance engineer ruled out that the fault was caused by the hydraulic oil. Through accurate inspection, the pressure when the arm was retracting is 340Bar, which directly indicates that there is no problem with the overflow valve.

Then the maintenance engineer removed the stick valve core from the valve body and found it was not stuck. He cleaned the valve core and observed that the valve core had not been worn by foreign objects, and there were no signs of serious strain, so it could be ruled out that the valve core had a problem.

The next step was to rule out the problem of the front and rear pumps of the main pump. The engineer swapped the oil outlet pipes of the front pump and the rear pump and tested the machine again. The fault did not change, indicating that the core main pump and regulator of the machine were not faulty. Seeing this, the owner was relieved about the excavator failure this time!

Finally, the most possible cause of the fault was the holding valve, so the engineer was very careful during the disassembly. As expected, after the holding valve was removed, it was found that internal wear was relatively serious. Therefore this was the cause of the failure.

After careful burnishing and cleaning, it was found that although the inside of the excavator stick holding valve was worn, the valve core could still be used, so after cleaning, reinstalling and restarting the machine, the fault disappeared!

Note: Here we would also like to remind all machine owners to decide the solution according to the situation, because the wear degree of the valve core of each machine is definitely different. Either it is so worn that the parts must be replaced, or it is slightly worn and can continue to be used after cleaning and polishing.

4. Conclusion

Although the fault was solved quickly, the owner regretted it after listening to the explanation of the maintenance engineer, because the excavator always worked in remote areas, and the owner did not replace the maintenance parts in time, and sometimes it was even long after the maintenance period before purchasing parts for replacement.

Long-term negligence caused the machine to run worse and worse, and minor and major faults came again and again, which eventually led to the machine being unable to work normally! So in terms of maintenance, we would like to remind all friends again, don't neglect it!