The basic knowledge of diaphragm coupling is very useful for air compressors, come and learn!

Coupling is a mechanical part used to connect two shafts (driving shaft and driven shaft) in different mechanisms to rotate together to transmit torque. In high-speed and heavy-duty power transmission, some couplings also have the function of buffering, damping and improving the dynamic performance of the shafting. The air compressor can be used to connect the main engine rotor and the motor.

Today, I will focus on introducing you to the diaphragm coupling. In fact, the diaphragm coupling is a kind of flexible coupling with elastic elements. This article introduces it separately to illustrate the importance of this type of coupling.

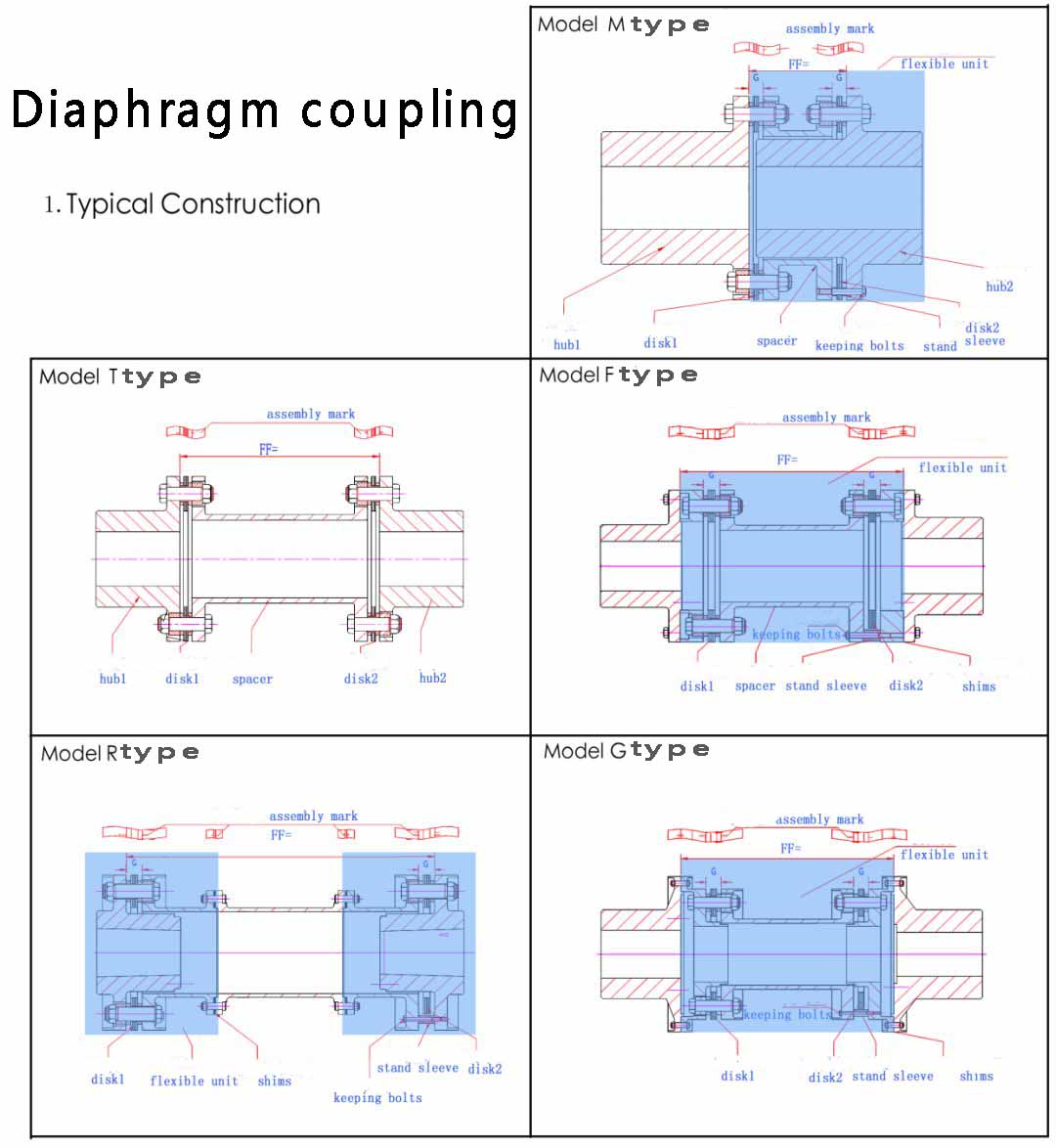

01, the structure of the diaphragm coupling

Diaphragm coupling is a metal flexible coupling, which is a transmission device that uses a metal elastic diaphragm as a flexible element to transmit torque. Its main features: large torque transmission capacity, diaphragm deformation to absorb the misalignment of the unit, no relative movement between the parts, no wear, no noise, long vibration damping life, and no lubrication. The torsional stiffness and critical speed can be adjusted by changing the outer diameter or wall thickness of the middle section, thereby improving the torsional vibration characteristics of the unit.

The diaphragm coupling is composed of at least one diaphragm and two shaft sleeves. The diaphragm is fastened to the sleeve with a pin and generally will not loosen or cause backlash between the diaphragm and the sleeve. Some manufacturers provide two diaphragms, and others provide three diaphragms, with one or two rigid elements in the middle, and the two sides are connected to the shaft sleeve. The difference between the single diaphragm coupling and the double diaphragm coupling is the ability to handle various deviations. In view of the complex bending of the diaphragm, the single diaphragm coupling is not suitable for eccentricity. The dual diaphragm coupling can bend in different directions at the same time to compensate for eccentricity.

02, the main characteristics of the diaphragm coupling

(1) The ability to compensate the misalignment of the two axes is strong. Compared with the gear coupling, the angular displacement can be doubled, the reaction force is small during radial displacement, the flexibility is large, and a certain axial, radial and angular displacement are allowed. To displacement.

(2) It has obvious shock absorption, no noise and no wear.

(3) Adapt to high temperature (-80+300) and work in harsh environments, and can operate safely under shock and vibration conditions.

(4) The transmission efficiency is high, up to 99.86%. Especially suitable for medium, high speed and high power transmission.

(5) Simple structure, light weight, small size, convenient assembly and disassembly. It can be assembled and disassembled without moving the machine (refer to the type with intermediate shaft), and no lubrication is required.

(6) It can accurately transmit the speed without slip, and can be used for the transmission of precision machinery.

The currently known diaphragm couplings can produce a maximum coupling transmission power of 50,000kw, a maximum speed of 80,000rpm, and a maximum of 12 meters. At present, the diaphragm coupling can be modified in many ways. As shown below:

03. The use of diaphragm coupling

Diaphragm couplings are widely used in shaft transmission of various mechanical devices, such as water pumps (especially high-power, chemical pumps), fans, compressors, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining Machinery, metallurgical machinery, aviation (helicopter), naval high-speed power transmission systems, steam turbines, piston-type power mechanical transmission systems, crawler vehicles, and generator sets high-speed, high-power mechanical transmission systems, which are applied to high-speed transmission after dynamic balance Shafting has become more common.

04, the reason for the abnormal noise of the diaphragm coupling

(1) The gap between the two halves of the coupling is too wide, causing the diaphragm to receive a greater axial force, which will cause the twisted holes or twisted bolts to wear and cause abnormalities.

(2) Excessive axial offset or too large deflection angle of the two halves of the coupling will also cause vibration and abnormal noise during equipment operation;

(3) The difference between the speed of the active end and the passive end will also cause vibration and abnormal noise when the equipment is running;

(4) The speed code plate of the motor is faulty, causing the speed of the motor to be fast and slow, and the diaphragm coupling makes abnormal noise.