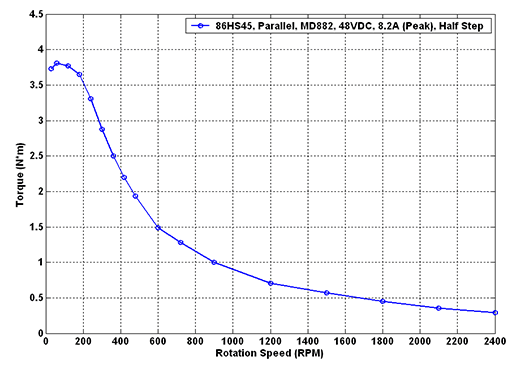

Figure 1: Stepper motor torque curve.

1. Related Terms in Stepper Motor Torque Curve Diagram

1.1 Holding Torque

This is the torque the motor will produce when the motor is stationary and rated current is applied to the windings. It is one of the most important parameters of the stepper motor, and usually the stepper motor torque at low speed is close to the stepper motor holding torque.

1.2 Pull-Out Curve

This curve represents the maximum torque that the stepper motor can provide to the load at any given speed. Any torque or speed required to exceed this curve will cause the motor to lose steps, so the motor must operate below this curve.

In fact, the torque-speed curve of the stepper motor is usually referred to as this curve.

How does the torque speed curve be formed?

First rotate the stepper motor to a certain speed with no load, then slowly apply torque to the output shaft through the brake, and measure the torque with a torque sensor until the moment when the motor loses synchronization (stops). Record the torque applied on the motor shaft at this time.

Repeat this process 3 times at each speed point, and then use the average of the three torque values as the value that will be displayed on the speed-torque curve. Repeat this process at multiple speed points, and you can create a complete torque speed curve.

1.3 Pull-In Curve

This curve represents the maximum torque and speed combination that the motor can be started or stopped with a load applied but without any acceleration or deceleration. In simple terms, this is the maximum speed at which at which the motor can be started, stopped, or reversed in an instant when a load is applied without losing synchronization.

The pull-in torque curve generally exists in the old product catalog. Because the motor could not run through the low resonance area before. It is necessary to introduce the pull-in torque to avoid excessive resonance.

However, with the development of microstepping technology, it is no longer necessary to start and stop at a predetermined speed, and there is no need to worry about input pulses causing out-of-step.

Figure 2: Stepper motor 28BYJ-48-5V.

1.4 Start-Stop Region

The start-stop range represents the working area where the motor can be started, stopped and reversed instantaneously without losing steps.

1.5 Slew Region

The slew range is the area between the pull-out torque and pull-in torque curves, and is also the range in which the motor usually operates.

The stepper motor cannot start and stop instantaneously in this area. It must start in the start-stop area, accelerate to above the pull-in torque curve, or decelerate in the slew range, and then stop in the start-stop area, otherwise it will lose steps.

Now, in the product catalog of the motor, the actual torque speed curve is often as shown below.

Figure 3: stepper motor vs servo torque.

A stepper motor of size 85mm, at a speed of 1000r/min, has a torque equivalent to the rated torque of a 400W servo motor.

It can be seen from the figure that the torque characteristics of the stepper motor are not flat, and the torque curve has a larger drop in the low/medium speed range, and a slower drop in the high speed range.

For short distance positioning, high torque in the low/medium speed range is crucial, which is one of the advantages of stepper motors.

In contrast, servo motors can generate smooth torque in the medium to high speed range and are suitable for long stroke operation.

1.6 Detent Torque

Detent torque refers to the torque at which the stator locks the rotor when the stepper motor is not energized. Since the rotor of the reactive stepper motor is not made of permanent magnet material, it has no detent torque.

2. FAQs on Stepper Motors

1.Why does the stepper motor torque decrease as the speed increases?

Figure 4: Torque frequency characteristic curve of stepper motor.

When the stepper motor rotates, the inductance of each phase winding of the motor will form a counter electromotive force; the higher the frequency, the greater the back electromotive force. Under its action, the phase current of the motor decreases as the frequency (or speed) increases, resulting in a decrease in torque.

2. Why can the stepper motor run normally at low speed, but cannot start if it is at a speed higher than a certain one, accompanied by whistling sound?

The stepper motor has a technical parameter: no-load start frequency, that is, the pulse frequency at which the stepper motor can start normally under no-load conditions. If the pulse frequency is higher than this value, the motor cannot start normally, and may lose steps or stall.

Under a load, the starting frequency should be lower. If you want to make the motor rotate at high speed, the pulse frequency should have an acceleration process, that is, the starting frequency is low, and then rise to the desired high frequency at a certain acceleration (the motor speed rises from low speed to high speed).

3. How to overcome the vibration and noise of the two-phase hybrid stepper motor at low speed?

When the stepper motor rotates at low speed, the vibration and noise are its inherent shortcomings. Generally, the following 5 solutions can be used to overcome these shortcomings:

A. If the stepper motor just works in the resonance area, you can let it avoid the resonance area by changing the mechanical transmission such as the reduction ratio.

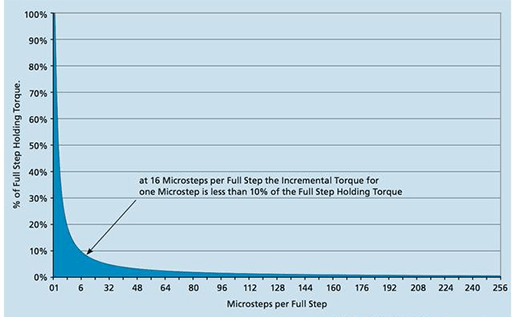

B. Adopt the driver with microstep function, which is the most commonly used and easiest method.

C. Change to a stepper motor with a smaller step angle, such as a three-phase or five-phase stepper motor.

D. Switching to an AC servo motor can almost completely overcome vibration and noise, but the cost is higher.

E. Add a magnetic damper to the motor shaft. This product can be seen on the market now, but the mechanical structure has changed a lot.

Figure 5: Relationship between the full step holding torque and the microsteps per full step of the micro-step drive.

4. What is the allowable surface temperature of the stepper motor?

If the temperature of the stepper motor is too high, the magnetic material of the motor will be demagnetized first, resulting in a decrease in torque and even loss of step. Therefore, the maximum temperature allowed on the motor surface should depend on the demagnetization point of the magnetic material of different motors.

Generally speaking, the demagnetization points of the magnetic material are all above 130 degrees Celsius, and some even up to 200 degrees Celsius or more, so the surface temperature of the stepper motor is completely normal at 80-90 degrees Celsius.

5. How to determine the DC power supply of the stepper motor driver?

A. Determination of voltage. The power supply voltage of the hybrid stepper motor driver is generally in a wide range. For example, the power supply voltage of IM483 is 12-48VDC. The power supply voltage is usually selected according to the working speed and response requirements of the motor. If the motor requires high speed or fast response when working, the voltage value should also be high, but pay attention that the ripple of the power supply voltage cannot exceed the maximum input voltage of the driver, otherwise the driver may be damaged.

B.Determination of current. The power supply current is generally determined according to the output phase current I of the driver. If a linear power supply is used, the power supply current is generally 1.1 to 1.3 times that of I; if a switching power supply is used, generally 1.5 to 2.0 times that of I.

If you have other problems about stepper motors, you can send us an email (service@okmarts.com), and we have dedicated service personnel to answer your questions.

Related Info

Some Common Questions about Motor TorqueStepper Motor: Working Principle, Operating Modes & Application

Types of Stepper Motors: Three Methods to Classify

Servo Motor vs Stepper Motor: Comparison from 9 Aspects

Torque Motor: Structure, Features, Types, Application