Figure 1: DC Micro motor.

A permanent magnet DC motor (PMDC motor) is a type of DC motor that uses permanent magnets to create a magnetic field. PMDC motors can be divided into permanent magnet brushless DC (PMBLDC) motors and permanent magnet brushed DC motors according to whether there are brushes.

Permanent Magnet Brushless DC Motor

Working Principle

The permanent magnet brushless DC motor is composed of a motor body and a driver (controller), and is a typical mechatronic product. Permanent magnet brushless DC motor is a DC motor with one or more permanent magnets to establish a magnetic field. Its performance is similar to that of a separately excited DC motor with constant excitation current, and the speed can be easily adjusted by changing the armature voltage.

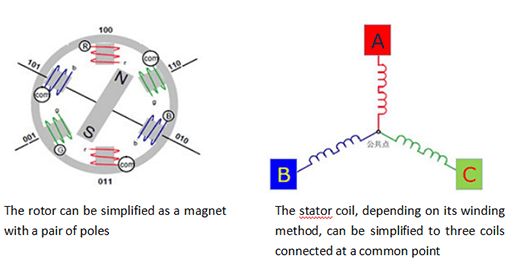

Brushless motors are also divided into inner rotor brushless motors and outer rotor brushless motors. The following takes an inner rotor brushless motor as an example. The stator windings of the permanent magnet brushless DC motor are mostly made into three-phase symmetrical star connection, very similar to that of a three-phase asynchronous motor.

The rotor is not a whole magnet, but a piece of magnetic tiles that are laminated together. There is also a position sensing device inside the motor body to provide the controller with a signal of the relative position of the rotor and the stator.

Figure 2: Simplified diagram of the rotor and stator coils of a permanent magnet brushless DC motor.

The driver is composed of power electronic devices and integrated circuits. Its functions are: receiving the start, stop and braking signals of the motor to control the start, stop and braking of the motor; receiving the position sensor signals and forward and reverse signals to control the on/off of each power tube of the bridge inverter to generate continuous torque; receiving speed commands and speed feedback signals to control and adjust the speed; providing protection and display, etc.

The permanent magnets N-S are exchanged alternately, so that the position sensor generates U, V, W square waves with a phase difference of 120°, which combined with the forward/reverse signals generate an valid six-state encoded signals: 101, 100, 110, 010, 011, 001. Through logic component processing, T1-T4 is turned on, T1-T6 on, T3-T6 on, T3-T2 on, T5-T2 on, T5-T2 on and T5-T4 on, which means that the DC bus voltages are added to A+B-, A+C-, B+C-, B+A-, C+A-, and C+B- in that order.

Figure 3: Energization method of brushless DC motor stator coils A, B, and C.

In this way, every time the rotor rotates through a pair of N-S poles, the T1-T6 power tubes are turned on sequentially in a fixed combination of six states. In each state, only two phase windings are energized. One state changed in turn, the axis of the magnetic field generated by the stator winding rotates 60° electrical angle in space, and the rotor follows the stator magnetic field to rotate the spatial position equivalent to a 60° electrical angle.

When the rotor is in a new position, the position sensors U, V and W generate a new set of codes according to the agreement, and the new codes change the conduction combination of the power tube, so that the magnetic field axis generated by the stator winding advances by 60° electrical angle. So the permanent magnet DC motor will generate continuous torque and drag the load for continuous rotation.

The position sensor codes of the permanent magnet brushless DC motor makes the position of the magnetic field axis of the energized two-phase windings ahead of the position of the rotor magnetic field axis, so no matter where the starting position of the rotor is, the motor will produce a large enough start torque at the moment of starting, and there is no need for a separate starting winding on the rotor.

Figure 4: Hall sensors for commutation used by brushless motor.

Types

According to the different permanent magnet materials used, permanent magnet brushless DC motors are divided into AlNiCo permanent magnet DC motors, ferrite permanent magnet DC motors and rare earth permanent magnet DC motors.

1. The AlNiCo permanent magnet brushless DC motor needs to consume a lot of precious metals and has a high price, but it has good adaptability to high temperature and is used in situations where the ambient temperature is high or the temperature stability of the motor is required to be high.

2. Ferrite permanent magnet brushless DC motors are known for their low cost and good performance, and are widely used in household appliances, automobiles, toys, power tools and other fields.

3. The magnetic poles of rare earth permanent magnet brushless DC motor are made of rare earth permanent magnet material. This motor is small in size and better in performance, but expensive, mainly used in aerospace, computer, downhole tools, etc.

However, in recent years, a new generation of rare earth permanent magnet DC motors, NdFeB permanent magnet brushless DC motors, have appeared, which have been widely used in industrial production, and also promoted the rapid development of the performance and structure of permanent magnet brushless DC motors.

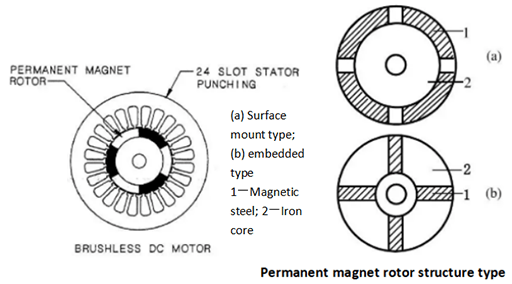

Figure 5: Rotor structure of permanent magnet brushless DC motor.

Advantages and Disadvantages

The main advantages of permanent magnet brushless DC motors are as follows:

1) High efficiency: The permanent magnet brushless DC motor has the highest efficiency among all motors, because the excitation uses permanent magnets and there is no power consumption. The absence of mechanical commutators and brushes means lower mechanical friction losses and therefore higher efficiency.

2) Small size: The introduction of high energy density permanent magnets (rare earth permanent magnets) enables the permanent magnet brushless DC motor to obtain a very high magnetic flux density, which accordingly makes it possible to obtain high torque, making the motor small in size and light in weight.

3) Easy to control: The permanent magnet brushless DC motor is as easy to control as the DC motor, because the control variables are easy to obtain and remain unchanged during the full operation of the motor.

4) Easy cooling: There is no circulating current in the rotor, so the rotor of the permanent magnet brushless DC motor does not generate heat, and only on the stator. The stator is easier to cool than the rotor because the stator is stationary and at the edge of the motor.

5) Low maintenance, significant long life and reliability: Without brushes and mechanical commutators, there is no need for related regular maintenance, eliminating the risk of failure of related components. Therefore, the life of the motor varies only with the winding insulation, bearing and permanent magnet life.

6) Low noise: Since the electronic commutator is used instead of the mechanical commutator, there is no noise accompanying with the commutator. The switching frequency of the drive inverter is high enough that harmonic noise is in the inaudible range.

However, the permanent magnet brushless DC motor also has the following disadvantages:

Figure 6: Electric motors.

1)Cost: Rare earth permanent magnets are much more expensive than other permanent magnets, which leads to higher motor cost.

2)Limited constant power range: It is impossible for a permanent magnet brushless DC motor to obtain a maximum speed that is more than twice the base speed.

3)Hazard: In the process of motor manufacturing, large rare earth permanent magnets may be dangerous because they can attract flying metal objects.

4)Magnet demagnetization: Permanent magnets can be demagnetized by large reverse magnetomotive force and high temperature.

5)Difficult to achieve high-speed performance: It is impossible for a motor with surface-mounted permanent magnets to achieve high speed because it is limited by the mechanical strength of the assembly between the rotor yoke and the permanent magnet.

6)Drive inverter failure of permanent magnet brushless DC motor: Since the permanent magnet is located on the rotor, the main danger presented by the permanent magnet brushless DC motor is in the event of a short circuit fault in the inverter. In this way, the rotating rotor is always excited, continuously inducing an electromotive force in the short-circuited windings.

In short-circuited windings, extremely large circulating currents and correspondingly large torques will block the rotor. High currents caused by inverter short circuits will put permanent magnets at risk of demagnetization and damage.

Related Info

Advantages, disadvantages and applications of linear motorsTop 10 Brands of Linear Motors

What is DC Motor and How Does It Work?

Types of DC Motors

What is Linear Motor and How Does It Work?