Video: Servo Motor Heat Dissipation: Overheating Reasons and Solutions

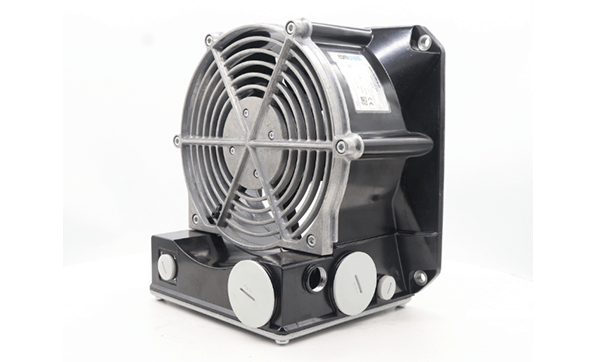

Figure 1: EBM-PAPST cooling fan for spindle servo motor.

Servo motor overheating has always been a headache and is an important factor causing motor shutdown and not to work consistently. How to solve the overheating problem of servo motors should start with source analysis.

First, find out the causes of the servo motor overheating, and then take corresponding solutions. Before introducing the causes and solutions of servo motor overheating, it is necessary to understand how servo motors dissipate heat usually.

1. How Servo Motors Dissipate Heat?

(1) Heat sink

Servo motors usually have heat sinks designed on the casing to increase the surface area and improve heat dissipation.

The heat sink can be connected to the internal heat source through thermally conductive materials, which conduct the generated heat to the heat sink.

Figure 2: Heat sinks for servo motors.

(2) Fan cooling

Some servo motors are equipped with fans to enhance cooling.

The fan can expel the hot air generated by the motor through forced convection and blow fresh cool air across the motor to reduce its surface temperature.

(3) Heat pipe

The heat pipe is an effective way of dissipating heat, which can conduct heat from the inside of the motor to the outside.

Heat pipes are usually made of thermally conductive materials and achieve heat transfer by connecting internal heat sources and external heat sinks.

(4) Use materials with good thermal conductivity

Choosing materials with good thermal conductivity, such as aluminum alloy, can improve the heat dissipation capacity of the servo motor. At the same time, you can also consider using materials such as thermal glue or thermal pads to improve the heat dissipation effect.

(5) Add heat dissipation holes or heat dissipation slots

Add heat dissipation holes or heat dissipation slots to improve the heat dissipation of the servo motor. Ensure smooth air circulation around the servo motor through a reasonable layout of the installation location to avoid clogging or blocking the heat dissipation vents.

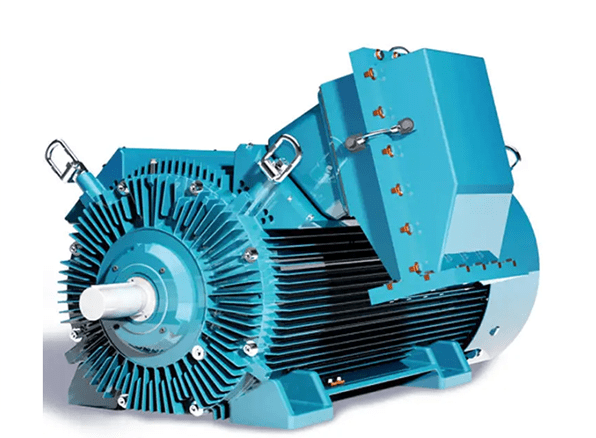

Figure 3: Servo motor.

(6) Install temperature sensor or thermistor

Some servo motors are equipped with temperature sensors that can monitor the temperature of the motor in real time.

When the temperature exceeds the set threshold, the system can automatically take measures, such as reducing power output or shutdown protection, to prevent overheating.

Next, let’s learn what may cause the servo motor to overheat.

2. Analysis of the Causes of Servo Motor Overheating and Solutions

Generally speaking, all types of motors have iron cores and winding coils inside. Windings have a resistance and when energized, they cause losses, which appear in the form of heat. Therefore, the phenomenon of servo motor generating heat is common. Here we mainly discuss the causes and solutions that may cause the servo motor to overheat and shut down.

2.1 Possible Causes of Servo Motor Overheating

What causes the servo motor to overheat? Generally there are the following possible causes:

1. Caused by harmonic interference of servo drive

The voltage waveform at the output end of the servo drive is not a standard sine wave, but a square wave. This waveform contains a large number of harmonics, which may cause the servo motor to overheat, vibrate, and howl, and accelerate its insulation aging (the servo motor is damaged fast). It may also cause the bearings to have burn marks, "pockmarks", small pits, and cracks, frequent breakdown of insulation (frequent breakdown of servo motors) and other series of problems. It is one of the more common causes of servo motor overheating.

Figure 4: Voltage and current waveforms at the output end of the servo drive.

2. Too high ambient temperature

This is easy to understand. When the ambient temperature is high, the temperature of the servo motor will naturally rise. Servo motors are usually designed to work in a specific ambient temperature range. If the temperature of the working environment exceeds this range, the motor may overheat. A high-temperature environment will reduce the efficiency of the motor and make it more likely to generate heat.

3. Poor heat dissipation

If the servo motor is installed in an electric control cabinet, poor heat dissipation inside will definitely affect the temperature of the servo motor. In addition, if the heat dissipation device of the servo motor itself works abnormally, it will also cause problems such as the servo motor overheating.

4. Servo motor selection problem

When selecting a model, choosing a smaller servo motor power or a lower torque will also cause the servo motor to overheat.

5. Low efficiency of servo motor

The low efficiency of the servo motor means that more electric energy will be used for heating, which will obviously lead to the problem of the servo motor overheating.

6. Works at full load for a long time

If the servo motor is always working at full load, it will cause the accumulation of heat energy. The longer the time, the higher the temperature of the servo motor will be. This is also a problem that requires special attention.

When selecting a servo motor, try to select a larger power and do not leave the servo motor at full load all the time. This will also help extend the service life of the servo motor.

Figure 5: Cooling fans and heat sink.

7. Servo drive parameter setting problem

If certain parameters of the servo motor are not set appropriately, it will also cause the servo motor to overheat, for example, parameters such as switching on and off frequency.

8. Servo motor overload

When a servo motor is subjected to a load that exceeds its rated load capacity, it causes the motor to overwork, thereby generating excessive heat. This may be caused by incorrect selection, increased mechanical resistance, sudden increase in load, etc.

9. Inappropriate current or voltage

If the servo motor receives unstable current or voltage, it may cause the motor to overheat. This may be caused by a power issue or an electrical connection issue.

10. Mechanical issues

Problems with the motor's mechanical parts, such as bearings and gearing, can cause additional friction and heat.

11. Other reasons

Other reasons include: servo motor quality problems, long working hours, etc.

2.2 Effective Solutions to Servo Motor Overheating Problem

If you want to completely solve the problem of servo motor overheating, you need to analyze the specific reasons. After determining the cause, the solution will naturally come...

1. Caused by harmonic interference of servo drive

MLAD-S-SC servo dedicated output filter, MLAD-SR-SC servo dedicated output reactor, MLAD-DW series Du/Dt filter, MLAD-SW sine wave filter and other special devices for harmonic suppression on the servo inverter side can be optionally installed.

Figure 6:Sine wave filter.

2. Too high ambient temperature

Just think of ways to lower the ambient temperature, such as installing air conditioners, fans, etc.

3. Poor heat dissipation

You can try to improve the heat dissipation conditions of the electric control cabinet, such as adding more cooling fan reasonably, etc.; if there is a problem with the servo motor's own heat dissipation, it should be solved quickly according to the specific problem, otherwise, the servo motor may stop working due to overheating.

4. Servo motor selection problem

Change to a servo motor with greater power or torque. When purchasing a servo motor, you need to select an appropriate motor model based on specific application scenarios and requirements to ensure that the motor has sufficient power and heat dissipation capabilities.

5. Low efficiency of servo motor

Choose a more efficient servo motor.

6. Works at full load for a long time

Replace with a servo motor with greater power or torque.

7. Servo drive parameter setting problem

Re-adjust the parameters of the servo driver so that they are at reasonable values, and the problem of servo motor overheating will naturally be solved.

Figure 7:TES servo motor and drive.

8. Other reasons

You can replace the servo motor with a new one or other methods to solve the problem of servo motor overheating.

To solve the problem of servo motor heating, you first need to determine the root cause of the problem. This typically requires diagnostics and inspections, which may require adjusting loads, improving cooling systems, ensuring power supply quality, inspecting mechanical components, and more. When dealing with servo motor overheating problems, it is best to seek help from professional engineers or maintenance personnel to ensure that the problem can be solved correctly.