Video: Wall Hung Condensing Boilers: Everything You Need to Know

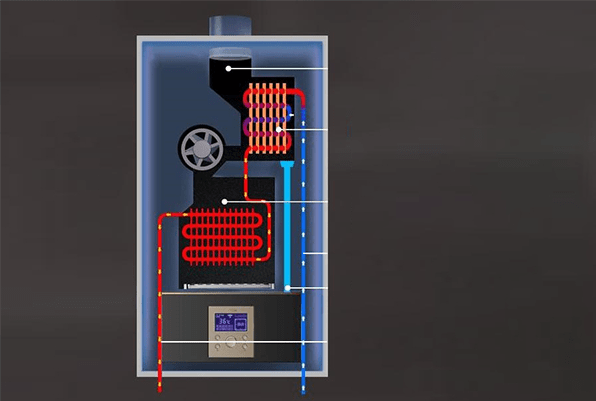

Figure 1: The inner structure of a wall-hung boiler.

Wall-hung boilers (for radiator heating or floor heating and water heating) have become the first choice of heating equipment for more and more families. Among them, wall hung condensing boilers are favored by the high-end heating market. Why are wall-hung condensing boilers so popular? Today let’s learn about the condensing wall-hung boiler in detail!

1. What is a Wall Hung Condensing Boiler? Working Principle of Wall Hung Condensing Boiler

Condensing technology is the most cutting-edge energy-saving technology in today's wall-mounted boiler industry.

This technology used in the condensing wall-hung boiler can recover the waste heat in the flue gas. The exhaust

temperature can be reduced to about 40°C, and the latent heat of water vapor in the flue gas can be fully absorbed

and utilized.

Coupled with premixed combustion technology that gas and air are mixed in proportion, the combustion is more

complete during the combustion process, the energy consumption of the condensing wall-hung boiler is lower, and the

environmental protection indicators are also more ideal.

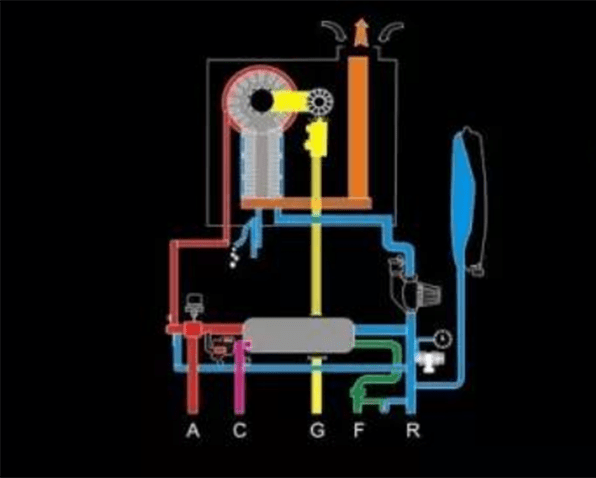

Figure 2: Working principle diagram of condensing boiler.

2. Types of Wall Hung Condensing Boiler

Condensing wall-hung boilers can be divided into two types according to their combustion methods, one is fully

premixed combustion and semi-premixed combustion.

Fully premixed combustion condensing boiler: The so-called fully premixed combustion means that the

gas and air are

fully mixed before entering the combustion chamber, thus ensuring high combustion efficiency and quality. However,

fully premixed combustion condensing boilers have high requirements for the quality of natural gas. If low-purity

natural gas is used, it is very easy to cause clogging and damage to the nozzles.

Semi-premixed combustion condensing boiler: Different from fully premixed combustion, the mixing

degree and quality

of natural gas and air are lower. Therefore, its thermal efficiency is lower than that of full premixed combustion.

Semi-premixed combustion condensing boilers have lower quality requirements for natural gas and will target a wider

user group.

Figure 3: Working principle diagram of fully premixed condensing boiler.

A. Hot water outlet C. Sanitary hot water outlet G. Gas inlet F. Tap water inlet R. Water return inlet

3. Condensing Boiler FAQs: Learn More about Condensing Boilers

3.1 What are the Combustion Methods of Wall Hung Condensing Boilers?

Condensing wall-mounted boilers are divided into two types: atmospheric combustion (semi-premixed combustion) and

fully premixed combustion.

The condensing wall-mounted boiler using atmospheric combustion mode fully absorbs the gas combustion products

through two heat exchangers: the sensible heat in the flue gas and the latent heat of water vapor.

The condensing wall-hung boiler that adopts the fully premixed combustion method fully mixes air and gas in advance

before burning. It is a completely new combustion method that is different from ordinary wall-hung boilers.

Atmospheric combustion means that a portion of air is premixed with before the gas reacts, but the

amount of oxygen required for combustion is not reached.

●Advantages: High flame temperature, medium flame length, obvious outer flame, relatively complete combustion, and

simple equipment.

●Disadvantages: Too large excess air coefficient and large heat waste.

Fully premixed combustion means that before the gas combustion reaction occurs, the gas and all the

air required for combustion are mixed evenly at one time according to the optimal combustion value, and can be

completely burned instantly after reaching the combustion zone.

●Advantages: Infrared combustion state, short flame or no visible flame, high temperature, complete combustion, few

harmful gas compounds, and high thermal efficiency.

●Disadvantages: Complex control equipment and procedures.

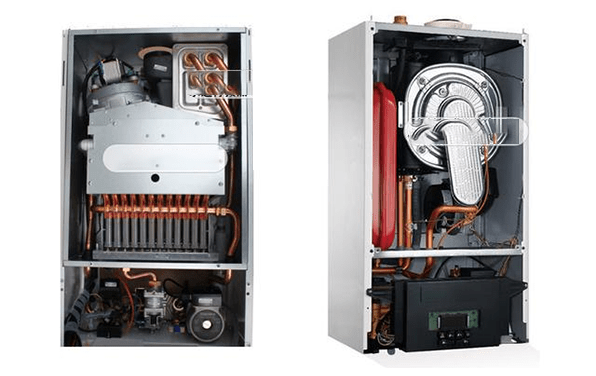

Figure 4: Boiler with secondary heat exchange vs. Fully premixed wall-hung boiler.

3.2 In What Aspects are the Energy Savings of Wall Hung Condensing Boilers Mainly Reflected?

1. Ultra-low flue gas temperature: In order to achieve the condensation effect and turn the water

vapor in the flue gas into water, the exhaust gas temperature must be lowered to reach the dew point temperature of

water vapor (55°C), which greatly reduces the heat loss (note: the exhaust temperature of ordinary wall-mounted

boilers is about 110℃-200℃, and that of the condensing boiler is between 30℃-50℃). This part of energy accounts for

about 30% of the total energy savings.

2. Adopt fully premixed combustion: Air and gas are fully proportioned in advance before

combustion. This combustion is the top combustion method in the combustion industry of gas appliances. Specifically,

it has fast combustion speed, short flame, or even no flame, high flame temperature, complete combustion, and small

excess air coefficient (that is, the flue gas emission is small. The excess air coefficient refers to the ratio of

the amount of air required for 1 cubic meter of gas combustion to the actual amount of air supplied). This part

probably accounts for about 20% of the total energy savings.

3. Fully enclosed combustion: When condensing wall-mounted boilers being designed, the fully

enclosed combustion is generally adopted, and the combustion flame is surrounded by heat exchangers, thus

effectively reducing the heat of the boiler itself. However, ordinary wall-mounted boilers only have the main heat

exchanger above the flame, which will cause heat loss around it. This part may roughly account for about 20% of the

total energy savings.

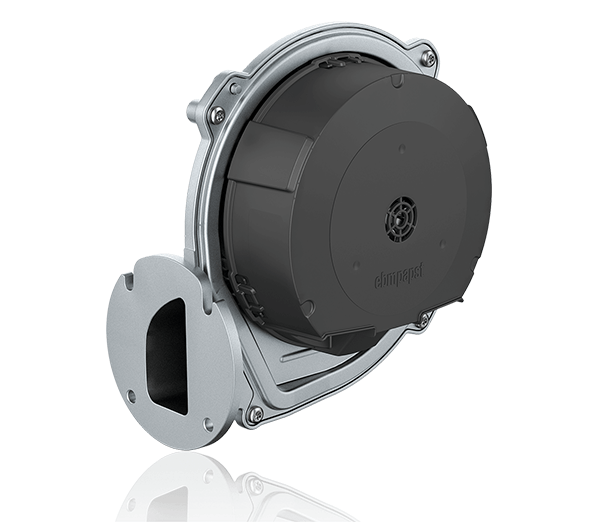

Figure 5: EBM gas blower.

3.3 What Kind of Wall-Hung Boiler is a True Wall Hung Condensing Boiler?

(1) Adopt fully premixed combustion technology.

(2) Low exhaust gas temperature, basically the same as the return water temperature.

(3) Have a certain amount of condensed water discharged.

(4) The air volume can be adjusted to make combustion more complete and the excess air coefficient reasonable.

(5) The main heat exchanger is made of acid-resistant materials, such as stainless steel, silicon aluminum.

Of course, there are also some wall-mounted boilers on the market that use atmospheric combustion, but a secondary

heat exchanger is added to the boiler to condense the flue gas.

Figure 6: Internal structure of fully premixed wall-hung boiler.

3.4 Why is the Wall Hung Condensing Boiler the Future Development Trend?

The condensing wall-hung boiler is a new type of energy-saving and environmentally friendly product. In today's era of energy shortage, the condensing boiler is the most energy-saving product among wall-hung boiler products, so it will inevitably become the direction of development.

Figure 7: Application of wall hung boiler.

3.5 Why Should the Condensing Boiler Heat Exchanger be Made of Stainless Steel?

Because condensed water is acidic and highly corrosive. The gas component contains sulfide, so the water generated

after combustion is also acidic, which has a strong corrosive effect on ordinary copper heat exchangers. So it is

necessary to use materials with strong corrosion resistance. At the same time, this material must also have strong

plasticity, good thermal conductivity, and low cost. After comparison, experts finally concluded that stainless

steel and cast silicon aluminum are the available materials.

O&Kmarts can provide ebm-papst gas blowers for wall mounted

boilers. If you have any need, please feel free to contact us!