Failure Forms and Preventive Measures of Parts of Shell and Tube Heat Exchanger

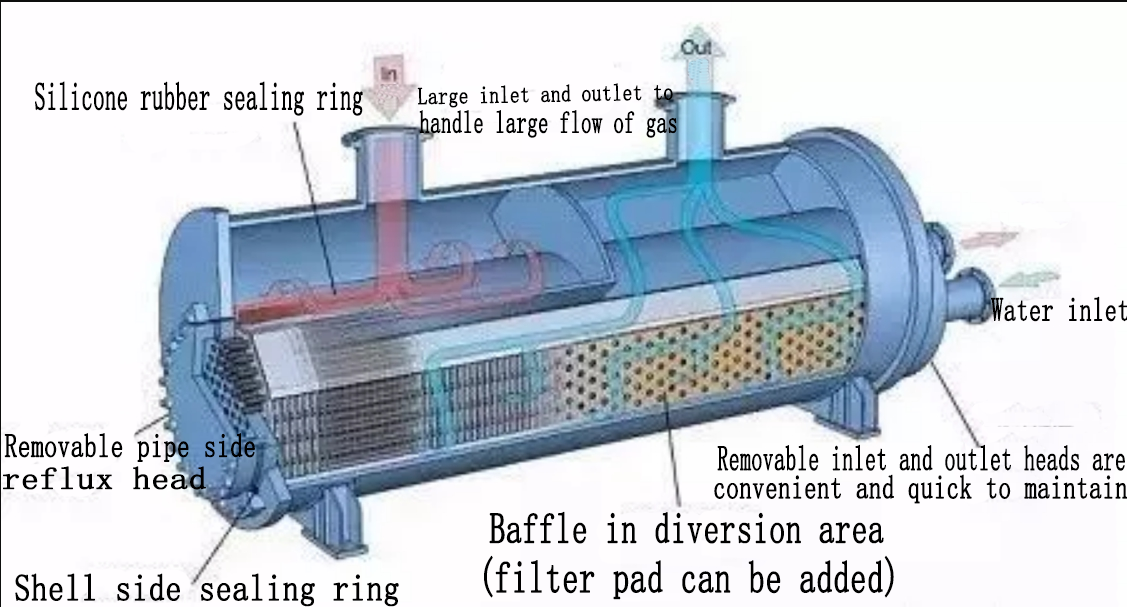

1. The structure of the shell and tube heat exchanger

The shell and tube heat exchanger is a traditional and most widely used heat exchange equipment. Because it has a strong structure and can be made of a variety of materials, it is highly adaptable. Shell-and-tube heat exchangers are widely used in various industries, and are often used as oil coolers in equipment thin oil stations in cement production enterprises and as oil coolers for vehicle engines.

For a long time, steel shell and tube heat exchangers have been dominant in the production and use of heat exchangers due to their strong structure, high reliability, strong adaptability and wide selection of materials. With the development of technologies such as enhanced heat transfer, shell-and-tube heat exchangers continue to improve in manufacturing technology and heat transfer performance. However, due to the complexity of the structure and the variety of operating conditions, the local failure or even the entire scrap of the heat exchanger often occurs.

Working principle of shell and tube heat exchanger

The main parts and components of the shell and tube heat exchanger include: cylinder, head, tube bundle, tube sheet, baffle plate, connecting pipe, flange, etc., under different working conditions and medium environment, various forms of Invalidate. From the structural analysis, the part that is prone to failure is the connection between the various components, such as the connection between the pipe and the tube sheet; from the perspective of the force, the surface of the structure is discontinuous, especially the sudden change of stress due to the presence of additional stress. Causes failures, such as the welding seam of the cylinder and the tube sheet; from the analysis of the working conditions, the thermal stress or additional stress caused by high temperature and high pressure, the corrosive working medium, and frequent shutdowns cause fluid induction of the heat exchange tube Vibration, etc., will cause the failure of the cylinder, heat exchange tube and even the whole machine.

Second, the reason for the shell and tube heat exchanger

1 Tube bundle corrosion and abrasion failure

Most heat exchanger failures are caused by corrosion. The most common corrosion location is the heat exchange tube, followed by the tube sheet, the heat exchanger head, and the small diameter pipe.

The main causes of tube bundle corrosion and abrasion failure are:

① Dirt corrosion;

②The fluid is corrosive;

③The accumulation of foreign matter on the inner wall of the pipe causes local corrosion;

④ Crevice corrosion occurs at the pipe end.

Preventive measures include:

① Clean the tube bundle regularly;

② Reasonable selection of materials;

③Add corrosion inhibitor to the fluid;

④Set up a filter device and a buffer structure at the fluid inlet;

2 Reduced heat transfer capacity

During the operation of the heat exchanger, due to the high hardness of the working medium, or the fluid containing particles and suspended matter, it will cause serious fouling on the inner and outer walls of the tube bundle. With the thickening of the fouling layer, the heat transfer resistance increases rapidly. In severe cases, the fouling will block the working medium flow path, which will lead to a rapid decrease in heat transfer capacity.

Prevention method:

① Fully grasp the easily contaminated parts, contaminants and the degree of dirt, and conduct regular inspections;

②When the fluid is easy to scale, equipment or structure that is easy to inspect, disassemble and clean must be adopted;

3 tube bundle leakage

In the case of heat exchange medium corrosion, stress corrosion, crevice corrosion or collision, abrasion, etc., microscopic cracks will occur on the pipe. If there is high tensile stress or alternating stress, the cracks will rapidly expand and leak. At this time, the method of pipe blocking is often used as an emergency repair measure. In fact, after the pipe is blocked, the temperature difference stress is increased, thereby accelerating its own stress corrosion, so the pipe will soon be more severely damaged, and the entire pipe bundle will be scrapped. The method of preventing tube bundle leakage should be considered from the aspects of material selection, corrosion prevention, damage prevention, reduction of tensile stress and prevention of vibration. Once the tube bundle is found to be leaking during the operation, the tube should be removed and replaced as much as possible without blocking the tube.

4 The connection between the tube bundle and the tube sheet fails

According to the different working conditions of the heat exchanger, the connection joints of the tube bundle and the tube sheet can be divided into three types: welding, expansion and expansion welding. Different joint forms have different failure modes. For products that are welded by conventional methods during welding, the welding method can be changed during major repairs to increase the strength of the weld between the heat exchange tube and the tube sheet.

① Change single-sided welding to double-sided welding;

②The flush welding structure of the tube plate and the front end of the tube bundle is a corner welding structure with the tube bundle extending a certain length. Special tooling is used to change the tube bundle and the tube sheet from the horizontal position to the vertical position, and change the heat pipe and the front side of the tube sheet. The vertical welding form is the horizontal welding form to meet the welding requirements of fillet welding.

By improving the welding process by the above two methods, good results can be obtained. The working environment of the cylinder failure shell and the tube bundle is basically the same, so the failure form and preventive measures of the shell can refer to the tube bundle.

Corrosion is the main failure form of shell and tube heat exchangers. In addition to the acidity and alkalinity of the heat exchange medium itself, which is corrosive, the corrosiveness of the working medium, the presence of tensile stress on the shell or tube, the existence of gaps between the tube and the tube sheet, etc. will accelerate corrosion, which will lead to heat exchanger failure prevention The main measures are: reducing the gap, choosing corrosion-resistant materials, improving the quality of the weld, cleaning it regularly, adding corrosion inhibitors to the fluid, controlling the temperature fluctuation of the system, and reducing flange connections.

3. On-line detection method for failure of shell and tube heat exchanger

1 scaling

After the heat exchanger is operated for a period of time, if the tube wall fouls seriously, the heat transfer capacity will decrease, and the outlet temperature of the heat exchange medium will not meet the design process parameters; the fouling will reduce the tube inner diameter; the flow rate will increase accordingly; the pressure loss will increase. At this time, the fouling situation can be judged by checking the operating records such as flow, pressure and temperature.

2 Corrosion and wear

The effects of heat exchange medium and dirt will cause corrosion and wear on the inner and outer surfaces of the heat exchanger shell and tube. A thickness gauge is usually used for the shell to measure and estimate the parts of the shell that will cause corrosion and thinning from the outside.

3 leaks

The middle of the pipe ruptured due to corrosion, induced vibration, etc. The pipe end leaked at the connection between the pipe and the tube sheet due to corrosion, fatigue damage, etc. The fluid sampling can be used to check the leakage and damage of the tube bundle.

From the above analysis, it can be seen that the failure of the shell-and-tube heat exchanger is related to a variety of factors such as the material structure, heat exchange medium and working conditions, and is sometimes the result of a combination of several factors. Therefore, various influencing factors should be comprehensively considered in the process of material selection, design, manufacture, assembly and use of heat exchangers to prevent problems before they occur.