Solenoid valves play a crucial role in controlling the flow of fluids or gases in various industrial and commercial applications. Among the different types available, two prominent ones are direct-acting solenoid valves and pilot-operated solenoid valves.

Understanding the differences between these two types is essential for selecting the right valve for specific applications. In this comprehensive guide, we delve into the workings, advantages, and ideal applications of each type.

1. Direct-Acting Solenoid Valve Basics

Direct-acting solenoid valves are simple yet effective devices that directly control the flow of media without the need for additional components. Here's how they work:

1.1 Working Principle of Direct-Acting Solenoid Valve

Direct-acting solenoid valves consist of a solenoid coil, a plunger, and a sealing element (such as a diaphragm or piston).

When an electrical current is applied to the coil, it generates a magnetic field, which pulls the plunger towards the coil's core.

This movement lifts the sealing element, allowing the fluid or gas to flow through the valve.

When the current is switched off, the plunger returns to its original position, closing the valve and stopping the flow.

1.2 Advantages of Direct-Acting Solenoid Valve

Simplicity: Direct-acting solenoid valves have a straightforward design with fewer moving parts, making them easy to install and maintain.

Fast Response: They offer rapid opening and closing times, making them suitable for applications requiring quick actuation.

Reliability: With fewer components, there are fewer points of failure, resulting in reliable operation over time.

Suitable for Low Pressure: Direct-acting solenoid valves are effective in low-pressure applications where the force required to open the valve is minimal.

1.3 Ideal Applications of Direct-Acting Solenoid Valve

Direct-acting solenoid valves are commonly used in applications requiring small flow rates or where space is limited.

They find widespread use in industries such as water purification, irrigation systems, beverage dispensing, and pneumatic control systems.

These valves are suitable for controlling the flow of water, air, oil, and other non-corrosive fluids and gases in low-pressure systems.

2. Pilot-Operated Solenoid Valve Basics

Pilot-operated solenoid valves are more complex than their direct-acting counterparts and are designed to control high-pressure or high-flow applications. Here's an overview of how they operate:

2.1 Working Principle of Pilot-Operated Solenoid Valve

Pilot-operated solenoid valves consist of two main chambers: a pilot chamber and a main valve chamber.

When an electrical current is applied to the solenoid coil, it opens a small pilot valve, allowing pressurized fluid or gas to enter the pilot chamber.

The pressure in the pilot chamber acts on a larger diaphragm or piston, which opens the main valve.

When the solenoid is de-energized, the pilot valve closes, and the pressure in the pilot chamber decreases, causing the main valve to close.

2.2 Advantages of Pilot-Operated Solenoid Valve

High Pressure Capability: Pilot-operated solenoid valves can handle higher pressures than direct-acting valves, making them suitable for high-pressure applications.

Large Flow Rates: These valves are capable of controlling large flow rates, making them ideal for applications requiring high flow capacities.

Versatility: Pilot-operated solenoid valves are adaptable to a wide range of fluid types and operating conditions, making them suitable for diverse industrial applications.

Reduced Power Consumption: Since the pilot valve requires less power to operate, pilot-operated solenoid valves can be more energy-efficient in certain applications.

2.3 Ideal Applications of Pilot-Operated Solenoid Valve

Pilot-operated solenoid valves are commonly used in industries such as oil and gas, petrochemical, power generation, and hydraulic systems.

They are suitable for controlling the flow of steam, gas, and other high-pressure fluids in pipelines, process equipment, and control systems.

These valves excel in applications where precise control of flow rates, high reliability, and remote operation are required.

3. Difference between Direct-Acting and Pilot-Operated Solenoid Valves

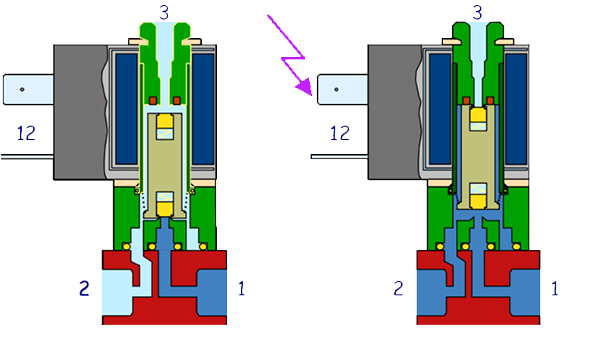

The primary distinction between these two types of solenoid valves lies in their operational mechanism. While direct-acting valves rely on the electromagnetic force to directly control the flow of fluid, pilot-operated valves use a pilot valve to regulate the flow to the main valve. This fundamental difference impacts their response time, flow capacity, and suitability for specific applications.

4. Choosing the Right Valve: Direct-Acting vs Pilot-Operated Solenoid Valves

Selecting the appropriate solenoid valve depends on various factors, including the application requirements, operating conditions, fluid characteristics, and budget constraints. Here are some key considerations:

1. Flow Requirements: Determine the required flow rate and pressure drop for your application to ensure that the selected valve can meet these requirements.

2. Operating Environment: Consider factors such as temperature, pressure, media compatibility, and environmental conditions to choose a valve that can withstand the operating conditions.

3. Response Time: Evaluate the required response time for opening and closing the valve to ensure that it can meet the demands of your application.

4. Energy Efficiency: Assess the power consumption of the valve and opt for energy-efficient options to minimize operational costs.

5. Maintenance Requirements: Consider the ease of maintenance, availability of spare parts, and service life of the valve to minimize downtime and maintenance costs.

5. Conclusion

Both direct-acting and pilot-operated solenoid valves play essential roles in controlling the flow of fluids and gases in various industrial applications. While direct-acting valves offer simplicity and fast response times for low-pressure applications, pilot-operated valves excel in high-pressure and high-flow situations, providing precise control and remote operation capabilities.

By understanding the differences between these two types of valves and considering the specific requirements of your application, you can select the right valve to ensure optimal performance and reliability.