Clean and dry compressed air drives the success of FCB

Compressed air is an important aspect of craft beer brewing, and no one knows this better than FCB (Five Churches brewing). FCB recently purchased and installed a suitable compressed air system from MACI (MidState Air Compr essor Inc.) for almost all aspects of beer production, including brewing, canning and barrel washing.

FCB (www. fivechurchesbrewing.com) and MACI (www.midstateaircom pressor. com) together chose to install a sliding vane air compressor assembly in the microbrewery to reliably and quietly deliver clean and dry air for brewing operations. The compressed air system allows FCB to not only continue to produce high-quality beer that customers appreciate, but also to continue to expand its booming business.

Craft beer and firewood pizza

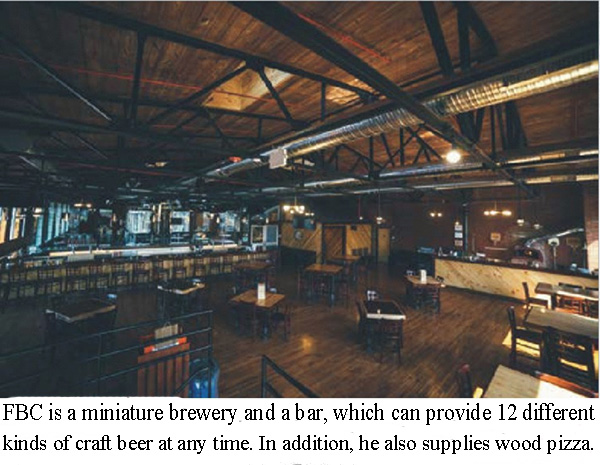

Located in the heart of New Britain, Connecticut, FBC is a microbrewery and a bar, owned by the Lemnotis family, and can offer 12 different craft beers at any time. In addition, it also serves firewood pizza.

This 100-person brewery and bar is different from most breweries because it is located on the second floor of the building and offers panoramic views of the city center. The first floor of the building is the transportation business of the Lemnotis family. Since opening in March 2018, this microbrewery has grown in popularity.

Clean, dry air is the top priority

When planning a microbrewery, the first task of FCB is to install a compressed air system that can provide clean and dry air for a variety of processes without any potential contaminants, including oil, water and particulates. Considering the key role that compressed air plays in the brewing process, the system also needs to operate reliably in the coming years.

After analyzing the FCB’s micro-factory and its compressed air demand plan, MACI of Berlin, Connecticut suggested installing a Mattei Blade 7SE quality air station, which is immersed in 7.5 horsepower (HP) oil lubricated with food-grade oil The sliding vane air compressor provides power. The rated gas delivery volume is as high as 36scfm at a pressure of 115psi.

According to MACI owner Salcalvo, the sliding vane air compressor unit is the best model of FCB for many reasons.

Calvo said: We work with many small breweries, but many wineries do not have the budget to support the upfront cost of oil-free scroll air compressors. However, they need a reliable system that provides clean, high-quality air to produce high-quality beer and prevent equipment damage. We have considered all these factors in the FCB system.

Calvo said that considering the reciprocating air compressors used in micro breweries and the compressed air conditions of typical breweries, the working cycle capacity of the air compressor is a major factor affecting compressor performance.

The production process in the winery requires continuous airflow, he said. We decided not to use reciprocating air compressors, because this type of unit is designed for intermittent use and does not require long working cycles like FCB. Calvo said: Improper use of reciprocating compressors can lead to premature system failures, production interruptions, and unnecessary service requirements. The sliding vane air compressor recommended for FCB also solves the need for clean air, which is essential to the safety and quality of craft beer. For this purpose, the FCB device is installed on an 80-gallon air receiving tank, providing high-efficiency oil/air separation, with minimal fuel consumption, and can carry up to one millionth to one millionth in compressed air The third motor oil.

The air compressor components include a built-in air-cooled aftercooler and a refrigerated air dryer with a 0.1 micron particulate filter installed on the inlet. The dryer also has a moisture separator and can automatically drain water regularly. MACI also installed a 0.01 ppm oil coalescing filter and a 0.003 micron activated carbon oil vapor removal filter downstream of the dryer to provide a higher level of filtration. MACI’s Kyle Wicklund is responsible for overseeing the FCB’s compressed air system installation. He said that considering this application, it is important for small breweries to install a suitable compressed air system.

Breweries need to follow FCB and make compressed air their top priority. When the goal is an efficient, pollution-free system, it is important to plan and budget for the right air compressor, dryer, and filtration system,; Wicklund said.

In addition to the air compressor and filtration system, MACI also designed and installed a piping system to provide stable air pressure and flow for each process. The system is composed of copper pipes to further ensure that the conveyed air is clean and free of particles. Since the brewery is visible to customers, MACI also chose copper pipes for aesthetics.

One of the key components of the brewery is a series of water tanks. Starting from the 40-barrel capacity water tank for storing and heating water, the heated water is poured into a 20-barrel malt mash barrel. This barrel combines water and barley malt. Mix together. This process is called malt transformation. This process uses natural enzymes in malt to break down malt starch into sugar. The wort vats can also filter grains and transform the mixture into a liquid called wort.

The wort is then transferred to a 20-barrel pot, and the wort is boiled for a period of time according to the brewing time of the beer. From the kettle, the sterilized mixture is sent to the fermenter, where yeast is added to the fermenter to convert the wort into beer by producing various flavors of alcohol. After maturity, the beer is carbonized and transferred to a bright beer tank, which supplies the consumable beer to the beer barrel and the canning production line of the operating mechanism.

With the help of the liquid sensor and the main PLC controller, clean compressed air powers up to 20 pneumatic valves for precise control of the transfer of hot water, wort and beer from one container to the next. In general, the compressed air pressure during the brewing process is between 95 and 130 psi, and the air consumption is 5-7 cfm.

FCB's chief brewer Jemps said that stable and reliable compressed air flow is essential to the brewing process, and equally important is the quality of compressed air.

The key is that the valve can be opened and closed immediately when called, because an interruption in the process can ruin the entire batch, causing us to lose thousands of dollars and a lot of productivity. The air passing through these ducts also needs to be as pure as possible, because we are producing a consumable.

Canning system optimized to increase production efficiency

In addition to supplying tap beer, FCB also sells other different types of beer. This small brewery can produce about 2,000 cans of beer every week.

A.B.E.'s CraftCan35TM canning system is the core of the canning operation, which relies on compressed air for operation. The self-contained canning machine is rated for canning, with a seam efficiency of up to 35 cans per minute.

The main components of the 8-foot-long, 2-foot-wide machine include a five-head/three-port online automatic filling machine with carbon dioxide purification control, a carbon dioxide gas channel, lid storage, servo sealing machine, air knife and conveying system. The programmable logic controller (PLC) controlled system is equipped with easy-to-move wheels, has a human-machine interface touch screen, and can also be controlled manually.

FCB's canning process starts with a depalletizer that automatically loads empty aluminum cans onto the canning system. The first station on the system rinses the empty tank with pure water to remove any potential dust or particles in the tank. These cans are then transported to the canning station, where they are cleaned with carbon dioxide to prevent the ingress of dissolved oxygen and filled with beer.

Before the machine puts the lid on the can, the system introduces another brief carbon dioxide explosion into the top of the can, and then the can is sent to the servo seam for sealing. Once stitched up, the jar will go through an external washing process, which includes drying with an air knife. As the last step, the staff manually affixed the labels and packed the cans for sale.

The compressed air system delivers 20cfm of air at 105psi pressure for conveying, filling, capping and drying. The motor controls the servo sealer, while another system provides carbon dioxide.

The compressed air system does a good job of providing a stable air supply at an appropriate pressure, which ensures that the canning system operates as designed. Jemps said, adding that since the company’s small brewing team includes two wine assistants who work closely with Jemps, production efficiency is critical. The end result is to fill the cans correctly at the required speed, without wasting beer or cans.

The barrel washing machine accelerates the barrel washing

Barrel cleaning is another process, requiring clean, dry compressed air at all times. FCB usually spends a full working day every week to wash the barrels.

Small breweries use automatically controlled A.B.E Keg CommanderTM washing machines to speed up the beer barrel washing process. The rated cleaning and blowing speed of the barrel-shaped gasket is 30 barrels per hour, and a 16-step cleaning cycle is adopted. The key components of the PLC-controlled machine include a double-head system for cleaning two barrels of different sizes at the same time, two independent tanks for cleaning solution and water, a low level sensor in the tank, and an HMI touch screen.

Jamps said that the importance of a continuous supply of clean, dry air for barrel cleaning cannot be underestimated. Clean compressed air is essential because we use it at the end of the cleaning cycle to eliminate all cleaning solutions, and then refill the beer barrels for consumption. Jemps said. When two empty barrels are manually placed on the machine's double-head mounting system, the barrel cleaning process begins. Then, the electric pump of the device injects cleaning fluid and water into the barrel. Next, pressurize the barrel with compressed air to drain the remaining solution, and then flow into the drain after the cleaning cycle is complete. Under a pressure of 75psi, each barrel must be flushed with 20 cfm of compressed air to ensure thorough flushing. In the final step, a separate system is used to purify each barrel and repressurize it with 20 cfm of carbon dioxide at a pressure of approximately 15 psi.

In addition to clean air, it is important to know that we can rely on a compressed air system to clean the bucket, otherwise we will spend a week cleaning the bucket manually, Jemps said. With this barrel washing machine, all we have to do is put the barrel on the machine and press the start button. The entire cleaning cycle is about 7 minutes, and we take out a clean wooden barrel to prepare for refilling.

Make beer and have fun

Since opening, FCB has experienced steady growth and has become more and more interested in bars and craft beer. Early success is a powerful sign of more success, especially because Connecticut is the birthplace of a booming craft beer industry based on high customer demand.

The craft beer market in Connecticut continues to grow, and competition continues, Jemps said. This means that we will continue to produce high-quality beer, which makes us stand out, and we also have fun in the process.