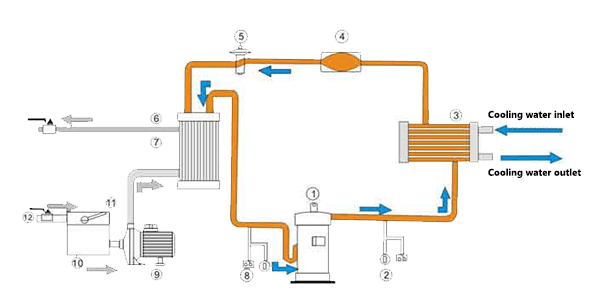

Figure 1: An ice maker.

An ice maker is a mechanical device that can cool water into ice through a refrigeration system. The ice made can be used for cooling food, and can also be used in the cooking process of food to increase the flavor and taste of food.

The ice maker will also have many faults due to long-term work. The following will carefully talk about the 14 common faults and solutions of the ice machine.

In addition, most ice makers will prompt the type of failure through the state of the indicator light when there is a partial failure. Therefore, check the fault code description of the machine before overhauling.

Fail to Making Ice

Analysis and solutions: The causes of the failure are:

1. The ice maker is not placed horizontally. Placed it horizontally as required;

2. The ice thickness sensor is damaged or the adjusted thickness is too small;

3. The solenoid valve is damaged;

4. Refrigerant leakage;

5. Compressor damage.

Not Making Ice When Compressor works

Reason: Refrigerant liquid leaks or the solenoid valve is damaged and can not close tightly.

Solution: After leak detection, repair the leak and add refrigerant or replace the solenoid valve.

1.Compressor; 2.High pressure controller; 3.Condenser; 4.Filter drier; 5.Expansion valve; 6.Frost protection switch; 7.Evaporator; 8.Low pressure controller; 9.Water pump; 10.Water tank; 11.Float switch; 12.lobe valve

Figure 2: Working principle diagram of ice maker.

Not Dumping Ice

Analysis and solutions: the compressor works normally, and the water pump keeps working to pump water. The ice cubes keep getting thicker, but the ice maker does not dump these cubes, which indicates that the control part has failed.

At this time, first adjust the ice cube thickness knob to see if the ice cubes thickness changes. If it changes, it indicates that the ice thickness sensor is normal, and the cause of the fault is that the electric control board is damaged. Otherwise, the ice thickness sensor is damaged.

It is also possible that the water temperature sensor is faulty. During the actual repair, put the water temperature probe in cold water and hot water successively, measure its resistance value with a multimeter, and compare these values to judge whether it is good or bad. If the water temperature detection probe is normal, the fault is on the electric control board.

Figure 3: The composition of the ice maker control board.

Not Easy to Dumping Ice

If the ice maker can dump ice cubes, but cannot do this smoothly or the dumping time is too long (more than 5 minutes), the reasons are as follows:

1. There are foreign objects attached to the surface of the evaporator, which is not conducive to ice making and dropping. At this time, the surface of the evaporator, the water line and water storage tank need to be cleaned;

2. Refrigerant leaks;

3. The heating valve is malfunctioning and will not open.

4. The water supply flow is small or the water supply valve is broken;

5. The thickness of the ice cube setting is too thick.

Compressor Working but Water Pump Not (No Water Flow)

Reason: The water pump is damaged or the inside of the water pump is blocked by scaling.

Repair: Clean the water pump or replace it.

Figure 4: Ice maker water pump.

Water Pump Working but Not Drawing Water

Analysis and overhaul:

1. If there is air in the pipeline, just discharge the air in the pump;

2. If there are too many ice slags at the bottom of the tank. At this time, it is necessary to stop the machine to discharge these ice slags, and then restart the ice maker;

3. The impeller inside the water pump is severely worn, and the pump needs to be replaced.

【Tips】During the actual repair, it was found that the damage of the water pump was mostly due to the excessive scale inside the pump, which caused it to be blocked and eventually burned.

Therefore, the ice-making water circulation system should be cleaned regularly to avoid excessive scale formation, so as to ensure that no excessive foreign material flows into the water pump.

Not Automatically Replenish Water

Reason: There is no water in the pipeline, or the water inlet solenoid valve is faulty, and does not open.

Analysis and solutions: first check the water inlet of the pipeline. If there is no water, you need to make the pipeline connect to the water source and restart the machine.

If the water inlet pipe is normal, it indicates that the water inlet solenoid valve is faulty and needs to be replaced.

Clogged Water Line

The water flow of the pipe is not smooth, and some ice cubes are incomplete.

Solution: In the state of controlled water flow, use tweezers or other sharp objects to clean the sundries attached to the water outlet hole, until the flow of water in each hole is unobstructed.

Figure 5: Ice cubes.

Analysis and solutions: If this phenomenon occurs shortly after the ice machine is used, the cause of the failure is that the floating ball of the float valve deviates and it cannot float up and down freely.

Remedy: Adjust the float valve so that the floating plane of the float is at the center plane of the water storage tank.

If this phenomenon occurs after the ice machine has been used for a long time, the cause of the fault is that the spool of the float valve is severely worn, which makes the water level control point of the float move up.

Remedy: Replace the float valve spool.

Power Indicator Keeps Flashing Rapidly, and the Machine Does Not Work

Fault: The water temperature sensor is disconnected.

Solution: Open the rear cover, open the electrical control box cover above the compressor, find a three-core connector, check whether there is any disconnection or poor contact, and reconnect it.

Figure 6: Samsung refrigerator ice maker control panel diagram.

Ice Full Light Flashing Fast

Analysis and solutions: This phenomenon indicates that the dropping ice time exceeds the specified time, and the machine starts automatic protection. Usually, rebooting will do the trick. If this phenomenon occurs repeatedly, check whether the ice cube tray swings up and down flexibly.

If the ice cube reaches the set thickness and enters the dumping state, the water pump stops working but the ice cube does not fall off. At this time, check whether the solenoid valve is normal. During the inspection, you can perform the dumping operation forcibly according to the method in the manual (press and hold the selection button for 3 seconds).

If there is no obvious air flow sound in the ice maker at this time, it can be determined that the solenoid valve is damaged. During the actual repair, you can first check whether the power supply of the solenoid valve is normal. If the power supply is normal, you can replace the coil and test the machine.

No Water in the Water Tank, but No Lack of Water Displayed

This fault is caused by the impurity left in the water of the water tank after multiple ice making, or the water is rich in minerals, which makes the surface of the water level probe scale and affects the detection sensitivity of the probe. It also makes the ice cubes be loose and have impurities.

Solution: Drain the remaining water, clean the inside of the water tank and the surface of the probe.

There is Water in the Water Tank, but Indicating Lack of Water

Solution: Check whether the two-core and three-core connectors in the control box are reliably connected, and re-plugging can usually solve the problem.

Automatic Shutdown

Figure 7: Air cooled ice maker.

4. Sight Glass

Analysis and solutions: The common cause of this failure is poor heat dissipation of the machine. Due to poor heat dissipation, the compressor becomes hot, triggering overheating protection and shutting down.

When repairing, first open the cover to see if the heat sink is dirty, or if there are other foreign objects hindering heat dissipation, if so, just clean the condenser.

If a fan is used for heat dissipation, first check whether the fan is running normally. There are also some ice machines that do not use air cooling, but discharge the heat in the condenser through water circulation (this method is called water cooling).

At this time, it is necessary to check whether the drainage and heat dissipation system is normal, and see whether there is water flowing out of the nozzle. Under normal circumstances, adjust the water valve so that there is just warm water discharged from the water outlet, which is more water-saving and environmentally friendly.

Related Info

15 Refrigeration System Components Structure, Function, Working Principle Diagram (1)15 Refrigeration System Components Structure, Function, Working Principle Diagram (2)

How to Quiet a Noisy Refrigerator (11 Ways)

How to Replace Refrigerator Compressor

How to Tell if Refrigerator Compressor is Bad