Figure 1:GMCC air conditioning compressor.

When the weather is very cold or hot, once the air conditioner fails, it will be miserable. So it is necessary to know the possible faults of an air conditioner refrigerator compressor and some preventive ways in advance.

In addition, before the change of season or after a long-term shutdown of air conditioning equipment, the entire air-conditioning system, especially the compressor, should be maintained to prevent it from malfunctioning during operation and avoid the air-conditioning equipment being paralyzed.

When the compressor in the external unit of the air conditioner is broken, the following phenomena may occur:

1. The air conditioner is not cooling.

2. It can't keep the temperature constant.

3. It will alarm and cannot be started.

4. It has loud noises, etc.

Let's take a look at the common faults of compressors in air conditioning maintenance!

1. Common Failure of Air Conditioning Compressor

1.1 Compressor Contactor Failure

The contact resistance of the air conditioner contactor is too large or sintered, which can easily cause the motor of the air conditioner compressor to be short-circuited and burned, or the circuit is poorly connected. A large starting current can easily burn out the air conditioner compressor.

Figure 2: Special contactor for air conditioner.

1.2 Unstable Power Supply Voltage

Too high or too low air conditioner power supply voltage will have adverse effects on the air conditioner compressor motor. Especially when the voltage exceeds the rated voltage range of the air conditioner compressor, long-term operation of the air conditioner will cause the compressor motor to be in an inefficient and overheated state, resulting in poor insulation and burnt motor windings.

In addition, the unbalanced three-phase voltage or current will also increase the loss of the motor (iron loss and copper loss), and causes problems that the temperature of the air conditioner compressor motor coil is too high, the overheater can not function properly, the insulation of the air conditioner compressor motor is burned, and eventually the air conditioner motor coil is short circuited and burned.

1.3 Compressor Rotating Parts Stuck

When this happens, if the motor protection fails, the air conditioner compressor motor may be overloaded and burned.

1.4 Wrong Wiring of Compressor

There is only one correct way to wire the compressor. Due to wrong wiring, the thermal protector may lose its protection function, causing the compressor to burn out (usually causing the secondary coil to burn out).

For three-phase compressors, there must be a phase sequence protection device.

Figure 3: Wiring diagram of single-phase compressor and three-phase compressor.

1.5 Refrigeration System not Thoroughly Cleaned

For the air conditioning and refrigeration system that once had a compressor burnout failure, the refrigeration system must be cleaned thoroughly. When the air conditioner compressor motor is burned, strong acid will be produced and stay in the system.

If it is not cleaned completely, when the new air conditioner compressor motor is running, the residual acid will corrode its insulation layer, causing the new air conditioner compressor to burn out.

1.6 Overload Operation

There are regulations on the maximum operating conditions of the compressor. If it exceeds the allowable range, the following consequences will result:

Due to the high exhaust temperature, the refrigerated oil on the surface of the exhaust valve is carbonized.

Due to the large pressure difference of the pump body, the moving parts are worn out.

The service life is reduced.

1.7 Foreign Materials Entering AC System

Sources of system residues may be:

1. Small copper shavings are produced when the copper pipe is cut.

2. Foreign matter such as processing oil and impurities in the system manufacturing process.

3. The compressor is exposed to the air for a long time, and dust and water vapor enter.

4. When welding, an oxide film will be formed on the inner surface of the pipeline, so the pipeline should be filled with nitrogen for protection during welding.

Figure 4: Small copper shavings in the compressor.

Effects of residues on the system:

It will aggravate the wear of the friction surface of the moving parts and block the oil pumping passage.

When the compressor contains moisture, fiber, dust and other tiny inclusions, these substances may be adsorbed on the motor winding and terminal, reducing the insulation performance of the whole machine.

Processing oil will also react with refrigerant or refrigeration oil to produce sludge and coke, which will adhere to the exhaust valve, suction filter and capillary, causing blockage.

1.8 Water Entering AC System

The moisture content in the air conditioner system should be controlled below 75ppm (recommended value).

Where is the moisture in the air conditioner system come from?

●During the manufacturing process, water enters air conditioners;

●The refrigerant contains more water;

●Water intrusion caused by system leakage;

●The compressor is improperly sealed;

●The vacuum degree of the system has not reached the standard.

1.9 Refrigerant Leak

The air conditioning system has reduced refrigerant due to leakage. After long-term operation of the compressor under this condition, the heat generated by the motor cannot be carried out by the refrigerant, and the exhaust temperature will increase accordingly.

When the temperature is too high, R22 begins to thermally decompose, producing acid and water. It will also make the carbon in the refrigeration oil dissociated to form carbon deposits. Refrigerant leakage can also cause poor oil return.

1.10 Insufficient Oil Return in System

The role of refrigeration oil:

Lubrication, effectively preventing wear of mechanical parts.

Oil seal, maintaining the high and low pressure difference.

Taking away the heat generated by friction in time.

If the refrigeration oil cannot return smoothly after being discharged, the oil return of the system is insufficient, resulting in:

Poor lubrication leads to wear and seizure of moving parts;

Reduced compressor capacity;

Overheating, etc.

Figure 5: Stuck compressor.

The main causes of poor oil return:

1.There is too much refrigerant, and the oil discharge volume increases;

2.The piping is not suitable (the piping is too long and the pipe diameter is large);

3.Operating under extremely low temperature conditions;

4.Intermittent running interval is short;

5.The amount of refrigerant circulation is small and the pressure is low;

6.Improper capillary, etc.

2. How to Avoid AC Compressor Breakdown?

2.1 Appropriate Interval for Switching on and off AC

Some consumers like to turn the air conditioner on and off frequently. For example, in summer, when they feel cool, they turn it off immediately, and turn it on again when hot. They think it can save power, but actually it does not.

The engineer suggested that the air conditioner should be controlled by itself (AUTO mode). According to the set program, the compressor can obtain better working efficiency.

At the same time, the air conditioner should be turned on after 3 minutes due to sudden power failure or artificial shutdown, otherwise some air conditioners without a time delay relay may burn the fuse or even the compressor motor due to excessive starting current.

2.2 Start the Compressor Once a Month

Even in the season when the air conditioner is not used, it is necessary to develop the habit of turning it on at least once a month. Because the compressor is a precision device, it is filled with lubricating oil to ensure the reliable operation of the compressor.

However, if the air conditioner is not used for a long time, the lubricating oil in the compressor may condense. When it is used under this situation, the compressor may be stuck and damaged.

2.3 Regularly Clean the Heat Sink

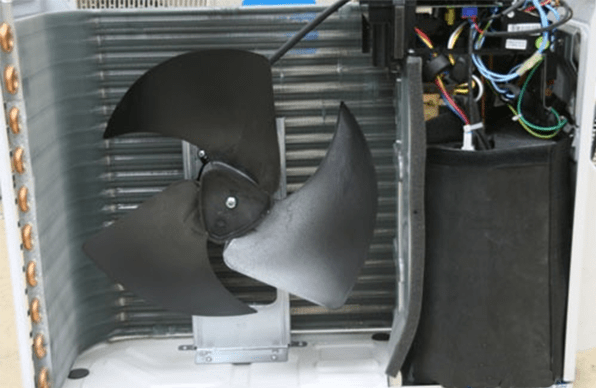

Figure 6: The internal structure of the outdoor unit of the air conditioner.

When the air conditioner is in use, the dust in the air will block the gaps in the heat sink, causing poor heat dissipation and increasing the pressure of the condenser. This will increase the current of the compressor motor and increase the power consumption of the air conditioner. Long-term high-power operation will damage the working life of the compressor.

Therefore, the engineer suggested that consumers should clean the heat sink regularly, and use canned detergent to spray from top to bottom at a distance of 4-6 cm away from the heat sink. Generally, when the air conditioner is frequently used in summer, it should be cleaned and disinfected once a month for better performance.

2.4 Prevent Compressor from Overheating

Figure 7: An air conditioner outdoor unit with shelter.

The compressor is installed in the outdoor unit. If the outdoor unit is often exposed to the sun, you can install an awning to create a better working environment for the compressor. And if the installation position of the outdoor unit has shelter, it is not necessary, because the outdoor unit has been designed with functions such as waterproof, acid proof and rust proof.

When installing the awning, consumers must pay attention to the size of it, because a too small awning will affect the heat exchange of the air conditioner. At the same time, it is also necessary to determine the distance from the awning to the front, back, left, and right of the air conditioner outdoor unit according to the instructions.

Related Info

How to Tell if the Home AC Compressor is BadDifferent Types of Refrigeration Compressors and Their Applications, Brands

Top 10 Industrial Compressor Manufacturers in the World

AC Compressor Failure and Case Analysis

What Type of Compressor is Used in Air Conditioner