Figure 1: Human-Machine Interface (HMI).

(Go to Okmarts and pick the HMI you need)

1. Overview

HMI stands for Human Machine Interface. These devices are also known as Man Machine Interface (MMI), Operator Interface Terminal (OIT), Local Operator Interface (LOI), Operator Terminal (OT), but for the purposes of this guide we will refer to them as HMIs.

An HMI is exactly what the name implies: a graphical interface that allows human users to interact with a system's machinery. As technology develops, HMIs are becoming more abundant in everyday tasks for consumers. Gas station pumps, self-service kiosks, ATM machines, and self checkout lines all use HMIs to process user inputs, convert them to machine readable code, and perform tasks without the need for an attendant, teller, or other employee. In the context of manufacturing and process control systems, an HMI provides a visual representation of the control system, and provides real time data acquisition. An HMI can increase productivity by providing a centralized display of the control process that is extremely user-friendly.

2. How Does a HMI Work

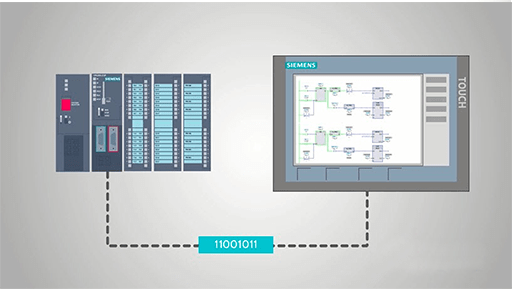

Figure 2: How does a HMI work.

HMIs are typically used in conjunction with a PLC (Programmable Logic Controller) to monitor and control processes in an automated system. In general terms, the HMI allows the user to communicate with the PLC via a graphical interface (typically a touchscreen). This interface allows commands to be given, and also receives and translates feedback data from the PLC, which is then presented in an easily accessible visualization on the screen. This provides the operator with much-needed flexibility and control over a given system. An excellent example of a common HMI would be a tablet or smartphone, which have built-in touchscreens that allow users to interact directly with the machine's programming.

3. Advantages of a HMI

Figure 3: Advantages of a HMI.

3.1 Advantages of an HMI over a PLC alone

Figure 4: HMI with a PLC.

A PLC on its own cannot provide any real-time feedback, and cannot set off alarms nor modify the system without reprogramming the PLC. The key advantage to an HMI is its functionality; an HMI can be used for simple tasks such as a coffee brewing controller, or as the sophisticated control unit of a nuclear plant. With new HMI designs emerging in the field, we are now seeing HMIs that offer remote access, allowing operators access to the terminal from a distance. Another advantage of an HMI is its customizability. The user can personalize the user interface for maximum ease-of-use.

3.2 Convenience

The convenience that comes with an HMI is invaluable, and the functionality achieved by digitizing a system with an HMI is unbeatable. An HMI combines all of the control features typically found throughout the automation line and places them in one centralized, remotely accessible location, eliminating the need, for example, to run to a red pushbutton to stop the production line in case of an emergency. With remote access, the operator does not need to be near the automation line to start, stop, or monitor production. The operator can access all the same controls on a centralized unit in a compact form. Simplicity is also a big factor in the usability of an HMI. The screens and functions provide for ease-of-use to supervise the automation line.

3.3 Interface Flexibility

One of the most valuable features of an HMI is the ability to personalize the interface. An HMI can fully support the most complex applications, with multiple screens and several routines running. If the user is looking to program an HMI with something more simplistic, they may write instructions for the controller directly into the HMI. Every HMI comes with different features: some may play sound or video, while others offer remote access control. The design of the user interface should be optimized for specific applications, taking into consideration all the capabilities of the typical user, as well as the environmental aspects such as noise, lighting, dust, vision and technological curves.

Related Info

What is HMI?Function and 7 Common Types of Solenoid Coil?

How To Replace A Solenoid Valve Coil?

6 Common Types of Power Supply