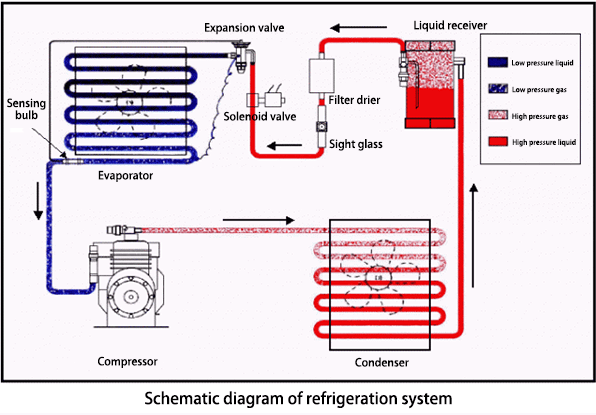

Figure 1: Vapor compression refrigeration system.

Vapour compression refrigeration system (VCRS) is the most common cooling system used in modern refrigeration technology. It uses gasoline, natural gas, liquefied petroleum gas or electrical energy as energy sources, and converts them into a useful available refrigeration effect, widely used in commercial, industrial, agricultural refrigeration equipment.

1. Main Components

The vapor compression refrigeration device is mainly composed of compressor, condenser, throttling device, and evaporator. In addition, it also includes auxiliary equipment such as oil separators and gas liquid separators (The purpose is to improve the economy, reliability and safety of refrigeration system operation), and instruments for control and measurement.

1.1 Compressor

The compressor is the heart of the refrigeration cycle, which plays the role of sucking in, compressing, and transporting refrigerant vapor. At present, the compressor used in the industry has two types: reciprocating and centrifugal type.

The work of a reciprocating refrigeration compressor is to rely on a variable working volume formed by the cylinder, the gas valve and the piston that reciprocates in the cylinder to complete the suction, compression and discharge of the working medium vapor. The centrifugal refrigeration compressor uses the centrifugal force generated by the impeller to compress and transport refrigerant gas.

Figure 2: Refrigeration compressor.

1.2 Condenser

The condenser is one of the main equipment in the vapor compression refrigeration system. Its role is to condense the high-temperature refrigerant vapor discharged by the compressor into a saturated liquid under condensing pressure. In the condenser, the refrigerant vapor transmits heat to the surrounding medium, such as water or air, so the condenser is a heat exchange equipment.

The condenser is divided into water-cooled condenser, air-cooled condenser, and evaporative condenser according to the cooling medium.

1.3 Throttling Device

The function of the throttling device is to make the liquid refrigerant from the condenser to produce a throttling effect to achieve the purpose of pressure and temperature reduction. As the evaporating temperature of the liquid in the evaporator decreases with the reduction of pressure, the refrigerant can be vaporized at a lower temperature after decompression.

Although the throttling device is a smaller part in the refrigeration system, it directly controls the refrigerant circulating volume of the entire refrigeration system. Therefore, its capacity and correct adjustment are the key to ensuring the normal operation of the refrigeration device. The capacity of the throttling device should be matched with the main component of the system.

The throttling device has many forms, such as manual expansion valve, capillary tube, automatic expansion valve, etc., and is usually chosen according to the characteristics of the refrigeration system and the type of refrigerant selected.

Figure 3: Expansion valve.

1.4 Evaporator

The evaporator is a heat exchange device that relies on the evaporation of the refrigerant liquid to absorb the heat of the cooling medium. Its task in the refrigeration system is to output cooling capacity to the outside.

The evaporator can be divided into: dry type and flooded type evaporator.

2. How Does the Vapour Compression Refrigeration System Work? (4 Stages of Vapor Compression Refrigeration Cycle)

The work process of vapor compression refrigeration system can be summarized as four stages:

2.1 Stage 1: Compression

To maintain a certain evaporation temperature, the refrigerant vapor must be continuously discharged from the evaporator. The refrigerant vapor from the evaporator is sucked in and compressed into high-pressure gases by the compressor. Since the compressor consumes a certain amount of mechanical energy during the compression process, and the mechanical energy is converted into heat energy during the process, the temperature of the refrigerant vapor rises a little and the refrigerant vapor is in a superheated state.

2.2 Stage 2: Condensation

The high-voltage refrigerant vapor discharged from the refrigeration compressor, releases heat in the condenser and transfers the heat to the surrounding medium—water or air, so that the refrigerant vapor gradually condenses into a liquid.

In the condenser, there are two basic conditions for refrigerant vapor to emit heat to the medium: First, the temperature of the refrigerant vapor must be higher than that of the surrounding medium, and maintain a proper temperature difference; second, according to the amount of refrigerant vapor sent by the compressor to the condenser, the condenser should have an appropriate tube length and area to ensure that the refrigerant vapor can be fully condensed in the condenser.

2.3 Stage 3: Throttling

The refrigerant liquid coming out of the condenser is decompressed to the evaporation pressure after passing through a decompression device (for example an expansion valve). The temperature of the throttled refrigerant also drops to the evaporation temperature, and part of the flash vapor is produced. The throttled air mixture enters the evaporator for the evaporation process.

2.4 Stage 4: Evaporation

After the liquid refrigerant flows into the evaporator through the throttling element, it starts to boil and vaporize due to the pressure drop, and its vaporization (evaporation) temperature is related to the pressure. In the process of liquid vaporization, it absorbs the heat of the surrounding medium—water, air or objects,to achieve the purpose of refrigeration. The vaporization of the liquid is a gradual process. In the end, all the liquid becomes dry saturated vapor, and then flows into the suction port of the compressor.

Figure 4: Schematic diagram of refrigeration system.

Summary: In the vapor compression refrigeration cycle system, the refrigerant gas enters the compressor under low pressure, and is compressed. With improved pressure and temperature, the gas is discharged into the condenser. After the high-temperature and high-pressure gas discharged from the compressor transmits heat to the outside air or cooling water, it is condensed into a liquid refrigerant flowing to the throttling device.

Because the throttling device can perform the effect of decompression and throttling, the pressure of the liquid refrigerant decreases after passing through it and then this type of low-pressure liquid flows into the evaporator. At this time, it absorbs the heat from the outside environment and evaporates into gas, thereby reducing the temperature of the outside environment.

After evaporation, the low-temperature and low-pressure gas is sucked back by the compressor for a continuous cycle of compression, condensation, throttling, and evaporation.

3. Pros and Cons of Vapour Compression Refrigeration System

Figure 5: Refrigeration unit.

Through the cooling cycle of the entire vapour compression refrigeration system, a large amount of cooling capacity can be released to meet the indoor cooling needs. In addition, based on the advantages of a vapor compression refrigeration system, it can achieve efficient refrigeration effects, energy saving, noise reduction, environmental protection, etc. Therefore, more and more industrial enterprises have begun to use vapour compression refrigeration systems.

The advantages of the vapor compression refrigeration system make it widely applied in the refrigeration field. However, the disadvantages of this system cannot be ignored, such as high maintenance costs, the cooling effect relying on environmental temperature, large operating loss of aging equipment, etc. When a problem occurs, it needs to be replaced or repaired immediately.

In short, the vapor compression refrigeration system is a highly efficient and reliable refrigeration system that is widely used in modern industry, but attention needs to be paid to system maintenance and repair work in order to give full play to its advantages.

Related Info

Types of Compressors for Air Conditioning and Refrigeration ApplicationsThe Difference between Hermetic and Semi-Hermetic Compressors

What is an HVAC System?

What Does the Compressor Do in the Refrigeration System

What are Refrigeration and Air-Conditioning Compressor Heaters Used For