Figure 1: DDA Tube Axial Fan 30 inch 22600 CFM Direct Drive 3 Phase DDA30T30750BM.

Axial fans, also called axial flow fans, are very versatile and produce airflow in the same direction as the axis of the fan blades. Both the electric fan and the outdoor fan of the air conditioner are axial fans. It is called "axial flow" because the airflow flows parallel to the axis of the fan. The axial fan is mainly composed of the fan impeller and the casing. The structure is simple but the data requirements are very high. Axial fans are usually used in applications with high flow rate and low pressure requirements.

The Working Principles of Axial Fans

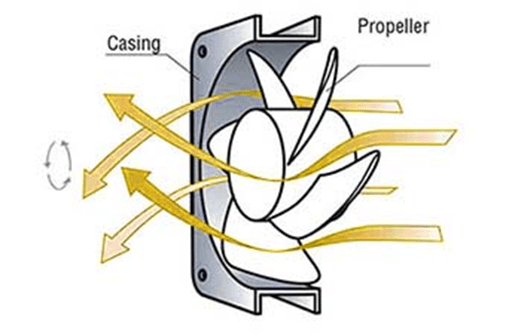

When the impeller rotates, the airflow enters the impeller axially from the air inlet. The blades on the impeller push the air flow so that its energy rises and it flows into the guide blades. The guide blades turn the deflected airflow into axial flow. At the same time, it guides the airflow into the diffuser, further converting the airflow kinetic energy into pressure energy, and finally guiding it into the working pipeline.

Figure 2: Structure and air flow mechanism of axial fans.

Axial fan blades work in a similar way to the wings of an airplane. However, the latter is to apply lift force up on the wings and support the weight of the aircraft, while the axial fan holds the position and moves the air.

The cross section of an axial fan is generally an airfoil profile. The blades can be fixed in position or rotated about their longitudinal axis. The angle of the blades to the airflow or the blade spacing can be non-adjustable or adjustable. The variability of blade angle and pitch is one of the main advantages of axial fans. Small blade pitch angles produce lower flow rates, while increasing pitch produces higher flow rates.

Advanced axial fans have the ability to change the pitch of the blades while the fan is running (similar to a helicopter rotor), thereby changing the flow rate accordingly. This is called a variable pitch (VP) axial fan.

Types of Axial Fans

Axial fans can be classified according to their characteristics as follows.

According to material: steel fan, glass fiber reinforced plastic fan, plastic fan, polypropylene (PP) fan, polyvinyl chloride (PVC) fan, magnesium alloy fan, aluminum fan, stainless steel fan, etc.

Figure 3: An axial fan made of plastic and aluminum.

According to usages: explosion-proof fan, corrosion resistant fan, explosion and corrosion proof fan, special axial fan, etc.

According to requirements of use: pipeline type, wall type, fixed type, rain and dust proof type, mobile type, motor external type, etc.

According to the installation method: belt drive type, motor direct wiring type.

The Energy Saving of Axial Fans

When the axial fan starts, the current of the motor will be 5-6 times higher than the rated value. This will not only affect the service life of the motor but also consume more power. When the system is designed, there will be a certain margin in the selection of the motor, and the speed of the motor is fixed. However, in actual use, sometimes it is necessary to run at a lower or higher speed, so it is very necessary to carry out frequency conversion transformation.

Figure 4: 1 kVA Frequency Converter 60Hz to 50Hz HZ-60-1101.

A frequency converter is a good choice. It can realize the soft start of the motor and, by changing the frequency of input voltage, regulate speed while saving energy. It can also provide protection in case of overcurrent, overvoltage, overload, etc.

Related Info

How to Make an Industrial Fan Quiet?How to Fix an Industrial Fan?

6 Common Electric Motor Failures and Solutions

What is an Industrial Fan?

How to Install an Industrial Exhaust Fan?