Figure 1: Expansion valves of different models.

The most common failures in the use of expansion valve are valve blockage, frosting, ice blockage and oil blockage. They make the refrigeration device unable to work normally, decreasing the refrigeration effect. The reasons for the above failures and the solutions are as follows:

1. Valve Blockage

Symptoms: compressor suction pressure drops sharply. The frost layer on the valve body of the expansion valve that works normally melts quickly and there is no full-flow sound that occurs during normal operation. Even if the valve body is showered with boiling water or heated with an alcohol lamp for several minutes, there is no response. Moreover, when the valve is removed for inspection, blockage is found in it, and the diaphragm can be pressed with fingers (note: it cannot be pressed with fingers when there is no leakage). Thereby, it can be determined that the temperature sensing system is faulty.

Causes: the expanded diaphragm ruptures, causing the leakage of the filler in the temperature sensing system; weld seam leakage occurs at the capillary tube or the temperature sensing bulb; or the capillary tube in the temperature sensing system ruptures due to excessive twisting. As a result, the pressure in the temperature sensing system is the same as the atmospheric pressure.

The above failures can make the pressure on the diaphragm decrease or disappear, so that the needle valve is pressed on the throttle hole (valve hole) under the action of the spring pressure below. And finally, the expansion valve is closed.

Solutions: deal with the leakage, replace the diaphragm or replace it with new parts if necessary, and then refill the temperature sensing bulb with the specified amount of refrigerant.

2. Frosting

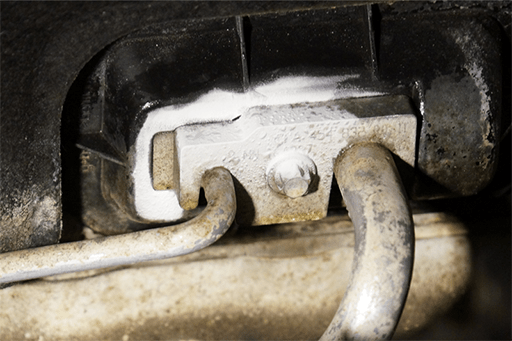

Symptoms: frosting on the valve body (valve inlet, outlet, small filter, etc.).

Figure 2: Frosty surface of the expansion valve.

Reason: when the inlet end of the valve is too small and the filter is blocked by impurities such as oxide scale in the pipes and components of the refrigeration system, the entire valve body will be frosted. When the blockage is serious, the frost layer at the outlet end of the expansion valve and the small filter will all melt. At this time, the suction pressure of the compressor will be lower, and heating the valve body cannot make it work normally.

Solution: remove the small filter of the expansion valve, clean it with anhydrous alcohol, dry it and then reinstall it.

3. Ice Blockage or Oil Blockage

Symptoms: the suction pressure of the compressor drops a lot, and the frost layer on the valve body is reduced or melted. After showering with boiling water or heating the valve body with an alcohol lamp for a few minutes, a short-term frosting phenomenon can be seen on the valve body. The sound of intermittent airflow can be heard, and the suction pressure rises. But soon these sounds gradually decreased, and the suction pressure gradually decreased. This can be judged as ice or oil blockages.

Check for ice or oil plugs: first remove the expansion valve, and then unscrew the valve seat. If there is viscous oil around the orifice, it is an oil blockage; if there are small ice particles and water droplets around the orifice, it can be judged as an ice blockage.

Solutions to ice blockage: install a liquid storage dryer in the refrigeration system, and run the compressor to absorb the moisture in the refrigerant until there is no ice blockage. It is better to use granular silica gel as desiccant.

Solutions to oil blockage: solve the failure of the oil separator or compressor, clean out the used refrigeration oil in the valve body and pipeline, and add the specified variety and quantity of refrigeration oil.

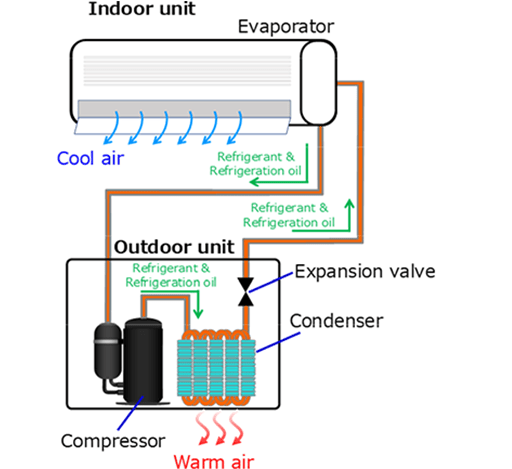

Figure 3: Example of refrigeration cycle: room air conditioner.

Related Info

Guides to Choose a Thermostatic Expansion ValveComparisons between the Electronic Expansion Valve and the Capillary Tube

6 Common Electric Motor Failures and Solutions

What is a Thermostatic Expansion Valve?

What is an Electronic Expansion Valve?