The frequency of air compressor lubricating oil replacement and matters needing attention

Generally speaking, technicians need to periodically sample the air compressor lubricant to determine whether the oil needs to be changed. We cannot generally determine a uniform compressor lubricating oil change time, because the structure of the compressor is different. Even if the structure is the same, the oil change time will be different due to the difference in the compression medium, operating conditions, compressor oil quality, and working environment. However, we can use scientific methods, a large number of experiments, and practical experience to determine the oil change index, that is, we often observe the color and cleanliness of the oil during the operation of the compressor, and regularly sample and analyze the viscosity, acid value, and normal of the oil. Physical and chemical properties such as insoluble matter.

If the oil change index is reached or exceeded, all or part of it should be replaced and refilled with new oil. Under normal circumstances, the oil in the oil cooler, oil and gas separator and oil circuit system can be replaced once every continuous working time reaches 2000-4000h, and the filter should be replaced or cleaned at the same time. In order to achieve the best results, the lubricating oil must be thoroughly cleaned. The cleaning steps include draining the old oil, removing the deposits, and flushing with new oil. After cleaning the system, if it is necessary to run-in, run-in 150-250 hours later, then let off the running-in oil.

We have separately analyzed two types of air compressors. If the following situations occur, you should consider changing the oil:

One, reciprocating air compressor oil

1. The oil has changed color, or the chroma has deepened by 4 or more;

2, the acid value exceeds 0.5mgKOH/g;

3, the viscosity change exceeds ±15%;

4, n-heptane insoluble matter exceeds 0.5%.

2. Lubricating oil for rotary air compressor

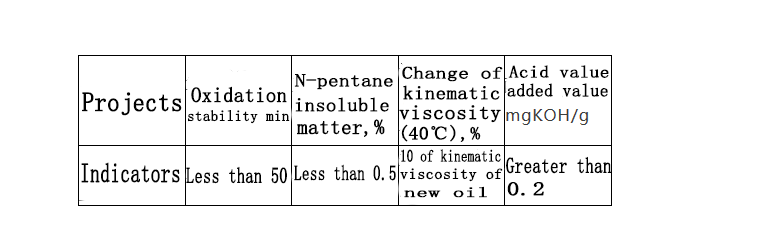

The oil change index of rotary air compressor (SH/T 0538-2000) is shown in the table below. With reference to the table below, when one of the following indicators is reached, new lubricants should be considered.

1. The lubricating oil used in the air compressor is a special air compressor special oil provided by the lubricating oil manufacturer. The lubricating oil has three functions: cooling the compressed air, sealing the rotor meshing gap, lubricating the bearings, shaft seals and gears. In fact, most of the oil is used to cool the compressed air. The oil that enters the compression chamber to cool the compressed air is in direct contact with the air at a working temperature of nearly 100 degrees, and is easily oxidized and deteriorated. Therefore, the cooling lubricant is required to have good oxidation resistance. . In addition, the contact between air and oil will cause part of the pressurized air to dissolve into the oil. After the air-dissolved oil enters the separator, once the pressure drops, the pressurized air dissolved in the oil immediately expands rapidly to produce a large amount of foam, which will seriously affect The performance of the oil requires the lubricating oil to have the characteristics of rapid defoaming and minimum air solubility.

2. The lubricating oil used in the air compressor is formulated with a special formula, which can not only give full play to the three functions of lubricating oil, but also has the characteristics of anti-oxidation, non-foaming and z*small air solubility.

3. The lubricating oil needs to be replaced after use, which should be determined according to the actual situation. Generally speaking, the lubricating oil must be replaced after 2000 hours of cumulative operation, but it also depends on the customer's usage and frequency of use. Sometimes, although the accumulated operation hours are less than 2,000 hours, the oil has not been changed for half a year, and the lubricant must be changed. Otherwise, the quality of the lubricating oil will be reduced, and it is easy to cause high temperature tripping failure. With the decline of oil quality, if the lubricating oil is not replaced in time, it is very easy to cause damage to the compressor head.