Figure 1: Notebook cooling module.

In the cooling module of the notebook, the three most critical elements are the heat pipe, the cooling fan and the cooling fins, and there are also elements used to improve the contact area and heat transfer efficiency between them.

1. Thermal Grease: Hidden Intermediate Medium and Filling Layer

The surface of chips such as the CPU, GPU, video memory and power supply module of many notebooks is covered with a

layer of copper integrated heat spreader (the metal “lid" of the CPU). As an "intermediary" between the chip and the

heat pipe, the primary task of the integrated heat spreaders is to quickly transfer heat from the chip body, and

they also have the effect of increasing the contact area and expanding the heat dissipation area.

In fact, there is still a layer of thermal conductive silicone grease as a filler between the chip and the

integrated heat spreader, and between the integrated heat spreader and the heat pipe. The surfaces of the integrated

heat spreader and the heat pipe should be finely polished—their surfaces are generally very rough, which will affect

the full contact with thermal grease on a microscopic level.

Figure 2: Structure of the contact surface between heat pipe and CPU from Intel.com.

After the metal surfaces are ground and polished using CNC and other processes, the contact area between them and

thermal grease can be maximized, so that heat can be conducted with 100% efficiency.

So far, in the process of "CPU/GPU → thermal grease → CPU cooler base plate → heat pipe", the heat dissipation

journey of the notebook has been halfway through, and the next step is how to transfer the heat to the outside.

2. Tasks from Heat Pipes

The heat pipe is a hollow metal pipe made of pure copper. The part close to the CPU/GPU chip is the "evaporation end", and the part in contact with the cooling fins is the "condensation end".

Figure 3: Heat pipe working principle diagram.

①. When the condensate is heated, it evaporates into steam to absorb heat energy.

②. The hot steam moves along the chamber to the condensation end with a lower temperature.

③. The steam condenses, returns back, and releases heat energy.

④. The condensate flows back to the higher temperature evaporation end.

The heat pipe is filled with condensate (such as pure water), and its working principle is that the high temperature

on the surface of the chip will convert the liquid at the evaporation end of the heat pipe into vapor (the boiling

point is very low in a vacuum state), which will move along the chamber to the tail of the heat pipe (condensation

end).

Because the temperature in this area (condensation end) is relatively low, the hot steam will soon become liquid,

and flow back to the original position along the inner wall of the heat pipe through capillary action, completing

the heat transfer again and again.

Unlike the cylindrical heat pipes used in processors and graphics cards in the desktop field, because the internal

space of notebooks is extremely limited, the core structure of the heat pipe must be flattened from the usual

cylindrical shape before it can be put in. Uneven or excessive flattening will hinder the transfer of liquid in the

pipe core, and excessive bending will also affect the flow passing through.

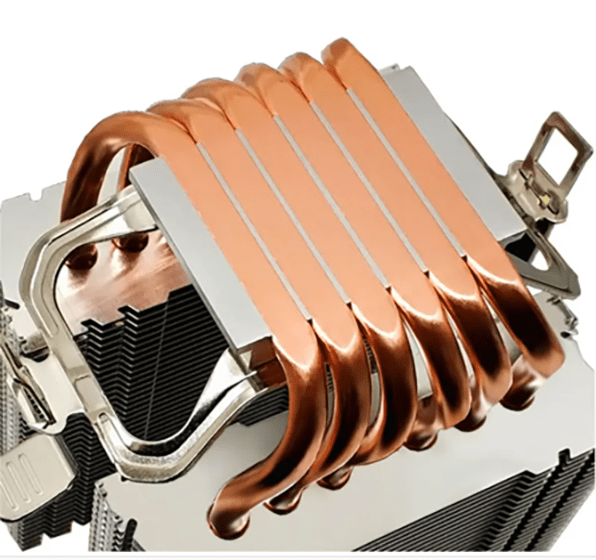

Figure 4: Cylindrical heat pipes.

3. Function of Cooling Fins

For the cooling module design of the notebook, the thicker the diameter of the heat pipe and the more the number,

the higher the heat transfer efficiency will be. However, in order to change the hot steam into liquid in the

condensation section of the heat pipe in the shortest possible time, higher requirements are needed on the matching

cooling fins.

Cooling fins are classified as "passive cooling elements" in the field of electronic engineering design. Its

materials are mainly aluminum and copper. The working principle is to dissipate the heat transferred from the heat

pipe in the form of convection. Its cooling efficiency depends on the size of the surface area.

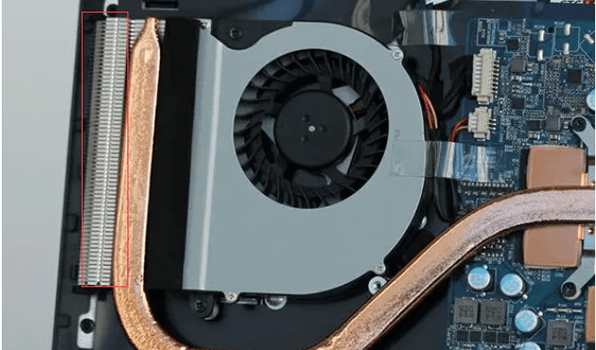

Figure 5: Cooling fin in a notebook.

Since even gaming notebooks are currently starting a "slimming competition", this leads to the fact that the cooling

fins can no longer get more surface area by increasing the thickness, but by increasing the length or number of

cooling fin modules, and the density of cooling fins.

It should be noted that, except for a few notebooks that adopt fanless design and pursue extreme thinness and

lightness, cooling fins cannot be used independently. A set of cooling fins must correspond to a cooling fan and a

hot air outlet.

The reason is simple. For notebooks equipped with 15W or higher TDP processors, the cooling fins cannot meet the

heat dissipation requirement from the chip at all, and the heat must be dissipated by the cold air sucked in from

the outside by the fan!