Illustrate the working principle and characteristics of various heat exchangers

1. Heat exchanger

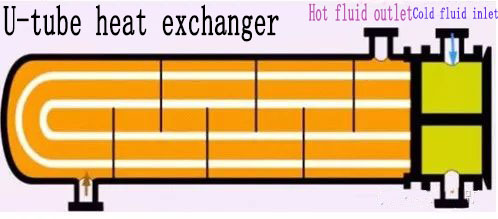

1. U-shaped tube heat exchanger

Each tube is bent into a U shape and fixed on the same side tube plate. Each tube can be freely expanded and contracted, also in order to eliminate thermal stress.

Performance characteristics:

(1) Advantages

The characteristic of this type of heat exchanger is that the tube bundle can be freely expanded and contracted, no thermal stress will be generated due to the temperature difference between the tube and the shell, and the thermal compensation performance is good;

The tube pass is a double tube pass, with longer flow, higher flow rate and better heat transfer performance;

Strong pressure bearing capacity;

The tube bundle can be drawn out from the shell, which is convenient for maintenance and cleaning, and has a simple structure and low cost.

(2) Disadvantages

It is inconvenient to clean the inside of the tube, the tubes in the middle part of the tube bundle are difficult to replace, and because the bending radius of the innermost tube cannot be too small, and the tube layout in the center of the tube sheet is not compact, the number of tubes cannot be too many, and there is a gap in the center of the tube bundle, which makes The shell side fluid is easy to short circuit and affect the shell side heat transfer.

In addition, in order to compensate for the thinning of the pipe wall after the elbow, a thicker pipe is required for the straight pipe. This affects its use occasions. It is only suitable for situations where the temperature difference between the tube and shell walls is large, or the shell side medium is easy to scale while the tube side medium is clean and not easy to scale, high temperature, high pressure, and strong corrosiveness.

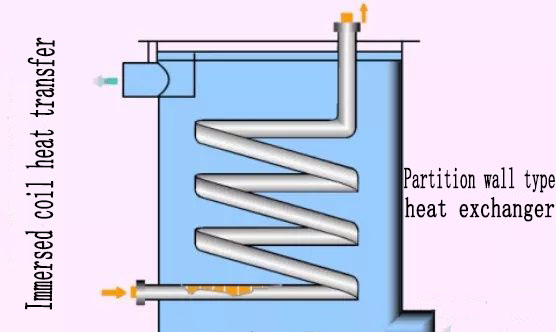

2. Immersion type snake tube heat exchanger

The immersed coiled tube heat exchanger uses a coiled tube as a heat transfer element and is one of the types of partitioned heat exchangers. According to the different cooling methods of the fluid outside the tube, the serpentine heat exchanger is divided into immersion type and spray type.

(2) Disadvantages

Because the volume of the container is much larger than that of the pipe, it is bulky and consumes more metal per unit heat transfer area, so the surface heat transfer coefficient of the fluid outside the pipe is smaller. In order to improve the heat transfer coefficient, a stirrer can be installed in the container.

3. Tubular heat exchanger

The cold fluid goes inside the tube, the hot fluid goes outside the tube through the baffle, and the cold and hot fluid exchange heat through the partition wall.

Performance characteristics:

The structure of the tube heat exchanger is relatively simple, compact, and inexpensive, but the outside of the tube cannot be mechanically cleaned. The tube bundle of the heat exchanger is connected to the tube plate, the tube plate is respectively welded to the two ends of the shell, and a top cover is connected to the tube plate, and the top cover and the shell are equipped with fluid inlet and outlet pipes. A series of baffles perpendicular to the tube bundle are usually installed outside the tube. At the same time, the connection between the tube and the tube sheet and the outer shell is rigid, and there are two fluids with different temperatures inside and outside the tube. Therefore, when the temperature difference between the tube wall and the shell wall is large, due to the difference in thermal expansion between the two, a large temperature difference stress is generated, so that the tube twists or loosens the tube from the tube sheet, or even destroys the heat exchanger.

In order to overcome the temperature difference stress, a temperature difference compensation device is necessary. Generally, when the temperature difference between the tube wall and the shell wall is more than 50℃, for safety reasons, the heat exchanger should have a temperature difference compensation device. But the compensation device (expansion joint) can only be used when the temperature difference between the shell wall and the pipe wall is lower than 60-70℃ and the fluid pressure in the shell side is not high. Generally, when the shell side pressure exceeds 0.6MPa, because the compensation ring is too thick, it is difficult to stretch and lose the function of temperature difference compensation, other structures should be considered.

4. Spiral plate heat exchanger

Two mutually parallel steel plates are rolled into mutually spaced spiral runners. Cover plates are welded on both ends of the spiral plate. The hot and cold fluids flow in the two flow channels respectively.

Performance characteristics:

(1) High heat transfer efficiency (good performance)

It is generally believed that the heat transfer efficiency of the spiral plate heat exchanger is 1 to 3 times that of the tubular heat exchanger. There is no flow dead zone in the uniform cross-section single channel, and the disturbance of the fixed distance column and the spiral channel reduces the critical Reynolds number of the fluid. When water-water heat exchange, the heat transfer coefficient of the spiral plate heat exchanger can reach 3000W/( ㎡·K).

(2) Effective recovery of low temperature heat energy

The spiral plate heat exchanger is made of two coils, which recover waste heat and make full use of low-temperature heat energy.

(3) Strong operational reliability

The end surface of the spiral channel of the non-detachable spiral plate heat exchanger is welded and sealed, so it has high sealing performance and ensures that the two working media are not mixed.

(4) Low resistance

The connection pipe on the shell adopts a tangential structure. Relatively low pressure loss, processing large-volume steam or gas; self-cleaning ability, because the medium flows in a spiral, dirt is not easy to deposit; easy to clean, can be washed with steam or lye, simple and easy, suitable for installing cleaning devices; The medium goes through a single channel, allowing the flow rate to be higher than other heat exchangers.

(5) Multiple units can be used in combination

When a single device cannot meet the requirements for use, multiple devices can be used in combination. But the combination must meet the following requirements: parallel combination, series combination, the same distance between equipment and channels. Mixed combination: One channel is connected in parallel and one channel is connected in series.

5. Spray heat exchanger

The hot fluid flows through the exposed tube, and the cooling water sprays through the coiled tube.

Performance characteristics:

This kind of heat exchanger fixes the heat exchange tubes in rows on the steel frame, the hot fluid flows in the tubes, and the cooling water is evenly poured down from the spray device from above, so it is also called spray cooler. The outside of the spray heat exchanger tube is a layer of liquid film with a higher degree of turbulence, and the heat supply coefficient outside the tube is much larger than that of the immersion type.

In addition, this kind of heat exchanger is mostly placed in a place where the air is circulating, and the evaporation of the cooling water also takes away a part of the heat, which can reduce the temperature of the cooling water and increase the driving force for heat transfer. Therefore, compared with the immersion type, the heat transfer effect of the spray heat exchanger is greatly improved.

6. Heat pipe heat exchanger

A sealed metal tube, the inner wall of the tube is covered with a core net made of capillary structure material, and the middle is empty. The tube contains a certain amount of heat carrier (such as liquid ammonia, freon, etc.), which is vaporized and flows to the cold end, where the steam is condensed at the cold end, releasing latent heat of vaporization, and heating the cold fluid. The condensate flows back to the hot end, and so on.

Performance characteristics:

(1) The heat pipe heat exchanger can completely separate the cold and hot fluids through the middle partition of the heat exchanger. During operation, when a single heat pipe is damaged due to wear, corrosion, over-temperature and other reasons, it will basically not affect the heat exchanger run. Heat pipe heat exchangers are used for fluids that are flammable, explosive and corrosive, and have high reliability in heat exchange situations.

(2) The cold and hot fluids of the heat pipe heat exchanger flow completely separately, which can easily realize the countercurrent heat exchange of the cold and hot fluids. Both cold and hot fluids flow outside the tube. Because the heat transfer coefficient flowing outside the tube is much higher than the heat transfer coefficient flowing inside the tube, it is very economical to use in low-grade heat energy recovery occasions.

(3) For fluids with higher dust content, heat pipe heat exchangers can solve the problems of heat exchanger wear and ash blocking through structural changes and expansion of the heating surface.

(4) When the heat pipe heat exchanger is used to recover the corrosive flue gas waste heat, the temperature of the heat pipe wall can be adjusted by adjusting the heat transfer area of the evaporation section and the condensation section, so that the heat pipe avoids the largest corrosion area as much as possible.

7. Double-pipe heat exchanger

The cold and hot fluids flow and exchange heat in the inner tube and the sleeve respectively.

(1) Advantages

This kind of heat exchanger has several outstanding advantages, so it is still widely used in petrochemical and other industrial sectors.

The structure is simple, and the heat transfer area can be increased or decreased freely. Because it is composed of standard components, no additional processing is required during installation.

High heat transfer efficiency. It is a pure counterflow heat exchanger, and at the same time, you can select a suitable cross-sectional size to increase the fluid velocity and increase the heat transfer coefficient of the fluid on both sides, so its heat transfer effect is good. When liquid-liquid heat exchange, the heat transfer coefficient is 870~1750W/(m2·℃). This is particularly suitable for the heat exchange of fluids with high pressure, small flow, and low heat transfer coefficient. The disadvantage of the double-pipe heat exchanger is that it covers a large area; the metal consumption per unit heat transfer area is about five times that of the shell-and-tube heat exchanger; there are many pipe joints, which are easy to leak; and the flow resistance is large.

The structure is simple, the working range is large, and the heat transfer area is easy to increase or decrease. The fluid on both sides can increase the flow rate, so that both sides of the heat transfer surface can have a higher heat transfer coefficient, which is a large metal consumption per unit heat transfer surface. In order to increase the heat transfer area and improve the heat transfer effect, various forms of fins can be added to the outer wall of the inner tube, and a scraping perturbation device is added to the inner tube to adapt to the heat exchange of high-viscosity fluids.

The form can be changed arbitrarily according to the installation position, which is conducive to installation.

(2) Disadvantages

Maintenance, cleaning and disassembly are troublesome, and it is easy to cause leakage at the detachable connection.

In production, many material choices are limited. Since most of the tube-in-tube heat exchangers do not allow welding in the inner tube, because welding will cause thermal expansion and cracking, and most of the tube-in-tube heat exchangers are selected to save space. Bending, the disc is made into a snake tube shape, so there are more special corrosion-resistant materials that cannot be produced normally.

There is no uniform welding standard for tube heat exchangers in China. Each company chooses the welding method based on the experience of other heat exchange products. Therefore, it is common for the welding of tube heat exchangers to have various problems and need to be checked frequently. ,maintenance.

2. Heat exchanger with compensation ring

1. Floating head heat exchanger

One section of the tube sheet at both ends is not connected to the shell and can float freely in the tube length direction. When the shell and the tube bundle cause different thermal expansion due to different temperatures, thermal stress can be eliminated.

Performance characteristics:

The structure is simple, but the heating surface is limited by the container wall, and the heat transfer coefficient is not high. In order to improve the heat transfer coefficient and make the liquid in the kettle evenly heated, a stirrer can be installed in the kettle. When cooling water or non-phase-change heating agent is passed into the jacket, spiral partitions or other measures to increase turbulence can also be arranged in the jacket to increase the heat supply coefficient on one side of the jacket. In order to supplement the lack of heat transfer surface, a snake tube can also be installed inside the kettle. Jacketed heat exchangers are widely used for heating and cooling in the reaction process.

3. Plate-fin heat exchanger

A unit body is composed of baffles, fins and side bars, and a plurality of unit bodies are assembled into an assembly through counter flow or cross flow, and then a collecting box with a collecting outlet is welded to the assembly. Due to the light and thin materials, the ratio of heat exchange area to heat exchanger volume can reach 4000 m2/m3.

Performance characteristics:

(1) The heat transfer efficiency is high. Due to the continuous rupture of the boundary layer due to the disturbance of the fins to the fluid, it has a large heat transfer coefficient; at the same time, because the partitions and fins are very thin and have high thermal conductivity, the plate-rib type The heat exchanger can achieve high efficiency.

(2) Compact, because the plate-rib heat exchanger has an extended secondary surface, its specific surface area can reach 1000 m2/m3.

(3) Lightweight, because it is compact and mostly made of aluminum alloy. Now steel, copper, composite materials, etc. have also been mass-produced.

(4) The adaptability is strong, and the plate-rib heat exchanger can be applied to: heat exchange between gas-gas, gas-liquid, liquid-liquid, various fluids, and phase-change heat with changes in state. Through the arrangement and combination of runners, it can be adapted to different heat exchange conditions such as counter flow, cross flow, multi-stream, multi-pass flow. The combination of series, parallel, series and parallel between units can meet the heat exchange needs of large-scale equipment. Industrially, it can be shaped and mass-produced to reduce costs, and interchangeability can be expanded through modular combination.

(5) The manufacturing process is strict and the process is complicated.

(6) It is easy to be clogged, not resistant to corrosion, and difficult to clean and repair, so it can only be used where the heat exchange medium is clean, non-corrosive, not easy to scale, not easy to deposit, and not easy to block.

4. Eddy current hot film heat exchanger

The volume of the flow film heat exchanger is only 1/5 of the traditional shell and tube heat exchanger, and it adopts an all-stainless steel welded structure. It not only has the advantages of small size and high temperature resistance of the brazed plate heat exchanger, but also overcomes the defects of aging and high maintenance cost of the frame plate heat exchanger. It uses the stainless steel vortex tube processed by nanotechnology as the heat exchange element. Greatly improve the overall performance of the heat exchanger.

Performance characteristics:

High efficiency and energy saving, the heat transfer coefficient of the heat exchanger is 6000~8000W/(m2·℃);

All stainless steel production, long service life, up to more than 20a, free replacement of heat exchanger quality problems within ten years;

Change laminar flow to turbulent flow, improve heat exchange efficiency and reduce thermal resistance;

Fast heat exchange speed, high temperature resistance (400℃), high pressure resistance (2.5MPa);

Compact structure, small footprint, light weight, convenient installation, saving civil construction investment;

Flexible design, complete specifications, strong practical pertinence, saving money;

Wide range of application conditions, suitable for large pressure, temperature range and heat exchange of multiple media;

Low maintenance cost, easy operation, long cleaning cycle, convenient cleaning;

Adopt nano thermal film technology to significantly increase the heat transfer coefficient;

It has a wide range of applications and can be widely used in thermal power, factories and mines, petrochemicals, urban central heating, food and medicine, energy electronics, machinery and light industry.