Figure 1: Various air cylinders.

(Go to Okmarts and pick the Air Cylinder you need)

1. Selection Process

There are various of Air Cylinder and it is very important to choose the appropriate model. We provide you with the process of air cylinder selection as follow.

1.1 Select Cylinder Series

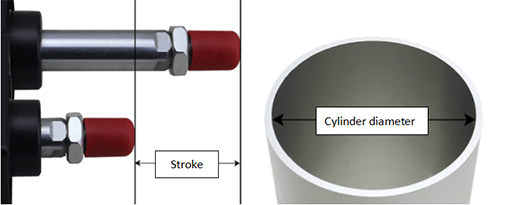

Select the appropriate cylinder series according to the purpose of use, cylinder diameter and stroke.

Figure 2: Select cylinder according to cylinder diameter and stroke.

1.2 Determine The Cylinder Diameter

Determine the cylinder diameter according to the load, running speed and working pressure. The steps are as follows: ① Determine the load weight (including the weight of movable parts such as workpiece, fixture and guide rod); ② Determine the air pressure (the compressed air pressure of the supply cylinder); ③ Determine the action direction of the cylinder.

1.2 Determine Cylinder Stroke

The stroke of the cylinder is related to the use occasion and the stroke ratio of the mechanism. In order to facilitate installation and commissioning, appropriate allowance should be made for the calculated stroke. Use standard strokes whenever possible to ensure fast delivery and reduce costs.

1.3 Determine Installation Form

It is determined by installation location, use purpose and other factors.

1.4 Determine The Buffer Form

Think about whether to use the buffer device according to the speed of the piston. Excessive load will make it difficult to absorb the impact capacity. So, it is necessary to design the buffer circuit or use the external buffer.

Figure 3: Buffer device of the air cylinder.

1.5 Determine Whether The Cylinder is Magnetic

The cylinder with magnetic switch can be selected when the pneumatic system adopts electrical control.

1.6 Select Accessories

Select accessories like solenoid valve, throttle valve, connector and even pipe, which seem insignificant but affect performance. Of course, as long as the problem of pneumatic selection is solved, others can basically be matched according to the demand.

2. What Factors Should be Considered

When selecting the air cylinder , we should comprehensively consider many factors.

2.1 Working Requirements

Correctly select the type of cylinder according to the working requirements and conditions. For example, if the cylinder is required to reach the end of the stroke without impact phenomenon and impact noise, please select the buffer cylinder; If light weight is required, please select light cylinder; If the installation space is required to be narrow and the stroke is short, please choose a thin cylinder; If there is transverse load, please select the cylinder with guide rod; If high braking accuracy is required, please select locking cylinder; If working in high temperature environment, please choose heat-resistant cylinder, etc.

and thin cylinder-min.png)

Figure 4: Heat-resistant cylinder (left) and thin cylinder (light).

2.2 Magnitude of Force

The thrust and tension output by the cylinder are determined according to the magnitude of the load force. Generally, the required cylinder force is balanced according to the external load theory, and different load rates are selected according to different speeds. Too short cylinder diameter will lead to insufficient output force. The long cylinder diameter makes the equipment bulky, increases the cost, increases the gas consumption and wastes energy. In the fixture design, the force expansion mechanism should be used as much as possible to reduce the overall dimension of the cylinder.

2.3 Movement Speed of Piston

This mainly depends on the input compressed air meteor of the cylinder, the size of the air inlet and exhaust port of the cylinder and the inner diameter of the conduit. The movement speed of the cylinder is generally 50 ~ 800mm / s. For high-speed motion cylinder, please select the intake pipe with large inner diameter; When it is is required to move smoothly (avoid impact), please select the cylinder with buffer device.

Related Info

How to Measure Air Pressure in A Cylinder?Comparison Between Air Cylinder and Electric Cylinder?

6 considerations when selecting plc

What is the difference between copper pipes using r410a refrigerant and r22

What are the input and output module i-o of plc