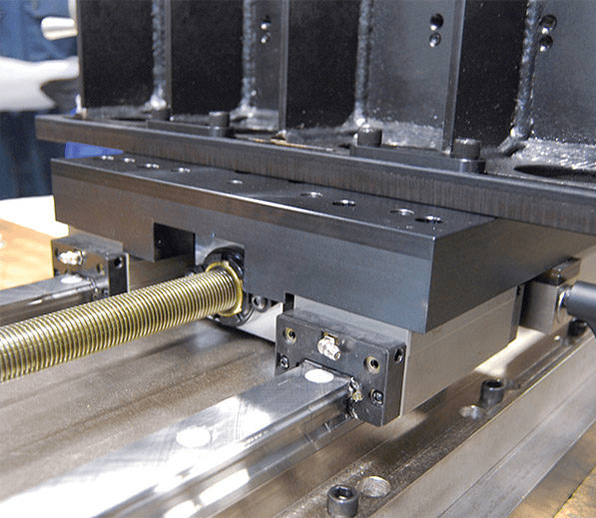

Figure 1: Linear guideways applied in machine tools.

The rolling element on the slider of the linear guideway moving back and forth inside the track groove will produce noise, which is a normal phenomenon. But if the noises are too loud or not the same as the noise in daily use, chances are that there is something wrong with the linear guideway. Here are some tips to deal with these abnormal noises.

1. Choose the Right Preload.

Different devices require different preloads and inconsistent preloads can cause noises. As for a linear guideway, preload is achieved by loading the guide block with balls whose diameter is slightly larger than the distance between the block and rail raceways. The grades of the preloads are divided into light, medium, and overweight preload. Here is a guide to choose the right preload.

1) Light preload: for equipment with a certain load direction, small vibration and impact force, and dual-axis use; and for equipment with low precision requirements and small sliding resistance. For example: laser welding equipment, binding equipment, automatic packaging machines, XY axes in common industrial machinery, automatic door and window processing equipment, welding machines, etc.

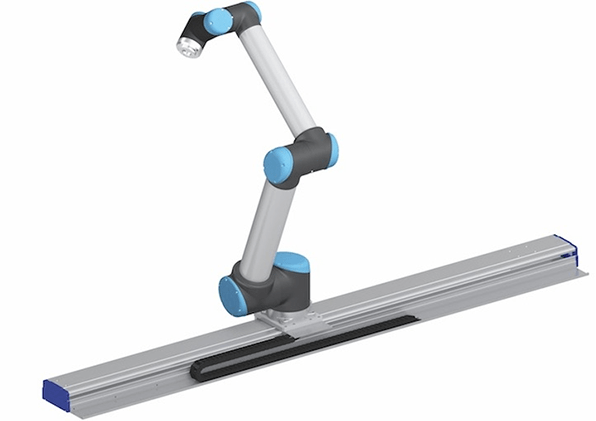

2) Medium preload: for equipment with cantilever load or moment; equipment used in single axis, light load and high precision equipment, such as the feed shaft of grinding machine table, industrial robot, measuring instrument, precision XY track, etc.

Figure 2: Linear guideway applied on industrial robot.

3) Heavy preload: for machinery with high rigidity requirements and large vibration and impact force, such as the Z-axis of work machinery.

2. Dustproofing

In operating conditions with too much dust, the linear guideway may produce abnormal noises. To solve this problem, we can choose a linear guideway with dustproofing devices, or certain slider according to the actual needs.

3. Correct Lubrication

Inappropriate lubricate grease can also give rise to unwanted noises during operation. To spare the difficulties of adding lubricant, some users may choose high-strength grease with very high viscosity, largely increasing the friction of the roller and aggravating the noise problem.

In other cases, some users don’t lubricate the linear guideway frequently enough, i.e., insufficient lubrication. This can also invite more noises and shorten the serve life of the linear guideway.

The solution is to choose the correct lubricant and lubricate sufficiently.

Figure 3: Lubricate the linear guideway.

4. Choose the Right Linear Guideway.

Some devices have very low loads, but some users don’t calculate their loads before selecting a linear guideway for them, and often overload them. This could reduce the serve life of the linear guideways and cause extra noises. Therefore, users should consult professional engineers when selecting and purchasing linear guideway products.

Related Info

How to Calculate the Service Life for Linear GuidewaysMaterials for Linear Guideways

Top 7 Linear Guideway Brands

How to Maintain a Linear Guideway?

The Lubrication of the Linear Guideway