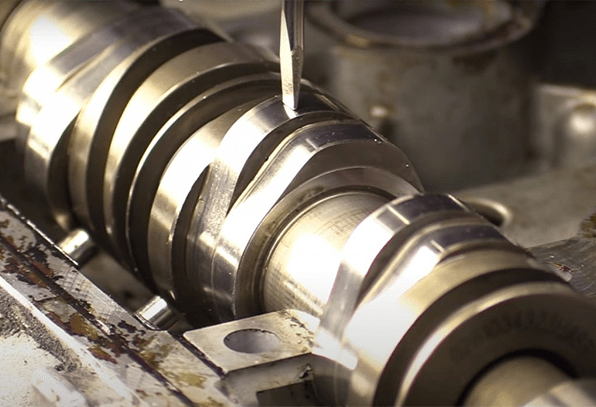

Figure 1: Variable valve timing solenoids used in cars.

The valve timing system of a traditional engine is a mechanical system in which the valve timing (i.e., valve opening and closing) remains unchanged. This kind of air distribution system is difficult to meet the needs of the engine for air distribution under various working conditions, and cannot meet the strong power requirements of the engine under various rotational speed conditions.

The variable valve timing system (VVT) is an electronic control system that changes the valve opening time or opening size. It matches the vehicle with more reasonable valve opening or closing timing at different speeds. This enhances the balance of the vehicle's torque output, increases engine power and reduces the vehicle's fuel consumption.

The VVT solenoid controls the left and right movement of the spool valve according to the duty cycle signal provided by the engine control unit (ECU), thereby controlling the direction of the oil passage on the camshaft. If the outflow direction of the lubricating oil is the same as the rotation direction of the camshaft timing gear, the valve opening is advance time; if it is the opposite, the valve opening is lag time.

In order to better illustrate the working process and working principle of the VVT system, the following takes the intake VVT as an example to describe its three most basic working processes:

1. Reference Position

The duty cycle of the pulse width modulation (PWM) signal input to oil control valve (OCV) is usually 0%, and the spool does not move. The oil pressure in the oil chamber on the right side of the phaser is greater than that on the left side. The left side of the blade rests on the stator shoulder, and there is no relative rotation between the rotor and the stator. The camshaft is not adjusted relative to the crankshaft timing. Usually, the intake VVT reference position is the intake valve phase lag position, i.e., the intake valve is opened and closed lag. This process is shown in figure 2.

Figure 2: The situation of PWM, rotor rotation, oil flowing at reference position.

2. Working Position

The duty cycle of the PWM signal input to the OCV gradually increases, and the spool moves to the farthest position. The pressure of the left oil chamber in the phaser gradually increases. After unlocking, the pressure in the oil chamber on the left is greater than that on the right. After overcoming the friction torque of the camshaft and the internal friction torque of the phaser, the rotor rotates clockwise relative to the stator. The camshaft is adjusted in the direction of timing advance, i.e., the intake valve will open and close in advance. This process is shown in figure 3.

Figure 3: The situation of PWM, rotor rotation, oil flowing at working position.

3. Stable Position

It is also known as control position: After the rotor rotates clockwise relative to the stator for a certain angle, the duty cycle of the PWM signal input to the OCV is about 50%. The oil cavities on the left and right sides of the phaser supply oil at the same time, and the rotor and stator remain in this relative position. Usually, after VVT is involved in adjustment, it works in a dynamic stable position at a certain angle most of the time. This process is shown in figure 4.

Figure 4: The situation of PWM, rotor rotation, oil flowing at stable position.

Related Info

What is a Directional Control ValveCommon Directional Control Valve Failures and the Solutions

What is a Variable Valve Timing Solenoid?

What is a Refrigeration Solenoid Valve?

5 Refrigeration Solenoid Valve Failures and the Solutions