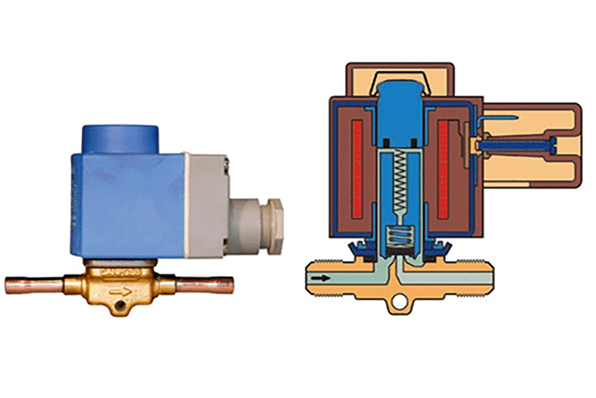

Figure 1: Solenoid valves for refrigeration systems.

The refrigeration solenoid valve is a valve that controls the automatic opening and closing of the refrigerant in the refrigeration system. It is composed of two parts: the valve body and the solenoid head, which are generally direct-acting. That is, the direct opening and closing solenoid valve uses the armature in the solenoid head to directly control the opening and closing of the valve hole, and the aperture is generally between 6-22mm.

Refrigeration solenoid valves are suitable for systems with no differential pressure or low pressure. The pulse solenoid valve inputs the positive pulse signal to the coil in the solenoid valve body through the wire. The working magnetic flux generated by the coil makes the moving core pull in and open the valve. Refrigeration solenoid valves can be divided into two types: direct acting and indirect acting. The solenoid valves used in commercial refrigeration equipment are generally direct acting.

Characteristics of Refrigeration Solenoid Valves

The refrigeration solenoid valve requires that the fluid in the pipeline must be consistent with the medium calibrated in the selected solenoid valve series model. And the temperature of the fluid must be lower than the calibration temperature of the solenoid valve. The allowable liquid viscosity of the solenoid valve is generally below 20CST, and it should be indicated if it is greater than 20CST.

In addition, the refrigeration solenoid valve has the following characteristics:

1. Special structure of recoil type integrating direct-acting valve opening and pilot-operating valve opening;

2. Zero pressure can also open the main valve. The flow rate of low-pressure difference is large, and the scope of application is wide;

3. Corresponding seals are required for different use media. This improves solenoid valve performance;

4. The valve plug adopts a one-time molding process, which further improves the life and reliability of the solenoid valve;

5. Precision cast copper body, exquisite and beautiful appearance.

Figure 2: Sectional view of a refrigeration solenoid valve in refrigeration system.

What do Refrigeration Solenoid Valves do?

The refrigeration system is divided into high pressure and low pressure, liquid and gas. In order to prevent the high-pressure liquid refrigerant from impacting the compressor after the compressor is stopped, a refrigeration solenoid valve is used to protect it. Before the compressor starts, the system pressure is in a balanced state, and there is no impact. At this time, the power supply of the solenoid valve is turned on, with the compressor started, and the refrigerant begins cooling process.

When the compressor is about to stop, the compressor is powered off or stopped, and the refrigeration solenoid valve is quickly cut off. The refrigerant on the high-pressure side does not return to the compressor in the opposite direction. Instead, it goes through the compressor in the direction of the cycle. Slowly, the entire refrigeration system and compressor stop, and the pressure returns to equilibrium.

Types of Refrigeration Solenoid Valves

1. Direct acting solenoid valve

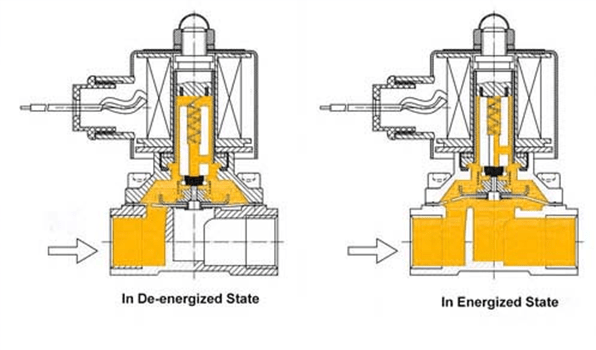

Figure 3: Direct acting solenoid valve in de-energized and energized state.

Working principles: When energized, the electromagnetic coil generates electromagnetic force to lift the closure member from the valve seat, and the valve opens; when de-energized, the electromagnetic force disappears. Also, the spring presses the closing member on the valve seat, and the valve closes.

Features: It can work normally in vacuum, negative pressure and zero pressure, but the diameter generally does not exceed 25mm.

2. Distributed direct acting solenoid valve

Working principle: It combines direct-acting and pilot-operating. When there is no pressure difference between the inlet and the outlet, after the power is turned on, the electromagnetic force directly lifts the pilot small valve and the main valve closure member upwards in turn, and the valve opens.

When the inlet and outlet reach the starting pressure difference, after power-on, the pressure in the lower chamber of the main valve rises and the pressure in the upper chamber decreases. And the differential pressure pushes the main valve upwards. When the power is off, the pilot valve uses the spring force or the medium pressure to push the closure member to move down, so that the valve closes.

Features: It can still operate under zero differential pressure, vacuum or high-pressure conditions. But the power is large and horizontal installation is required.

Related Info

Tips for Solenoid Coil WindingHow to Improve the Quality Factor of the Solenoid Coil?

What is a Color Coded Inductor Coil?

How does Solenoid Coil Work?

Parameters of the Solenoid Coil