Figure 1: BITZER scroll compressors.

Compressors are essential components in air conditioning and refrigeration systems. They are responsible for compressing the refrigerant gas, which is then circulated through the system to absorb and release heat. One type of compressor that has gained popularity in recent years is the scroll compressor.

In this article, we will take a closer look at how a scroll compressor works, including its components, operating principles, advantages, and disadvantages.

1. What is a Scroll Compressor?

A scroll compressor is a type of positive displacement compressor that uses two intermeshing spiral-shaped scrolls to compress the refrigerant gas. The scrolls have a fixed and an orbiting component, with the orbiting scroll moving around the fixed scroll.

As the orbiting scroll moves, it creates pockets of gas between the scrolls, which get smaller as they move towards the center. This process compresses the gas and increases its pressure.

Components of a Scroll Compressor

A scroll compressor consists of several main components, including:

Fixed scroll: The fixed scroll is a stationary component that contains a spiral-shaped groove. The groove is designed to trap gas as it is compressed.

Orbiting scroll: The orbiting scroll is a rotating component that fits inside the fixed scroll. It contains a spiral-shaped groove that meshes with the fixed scroll and compresses the gas.

Motor: The motor is the component that drives the orbiting scroll. It is typically an electric motor that provides the necessary power to rotate the scroll.

Inlet and outlet ports: The inlet port is the point where gas enters the compressor, while the outlet port is the point where compressed gas is discharged from the compressor.

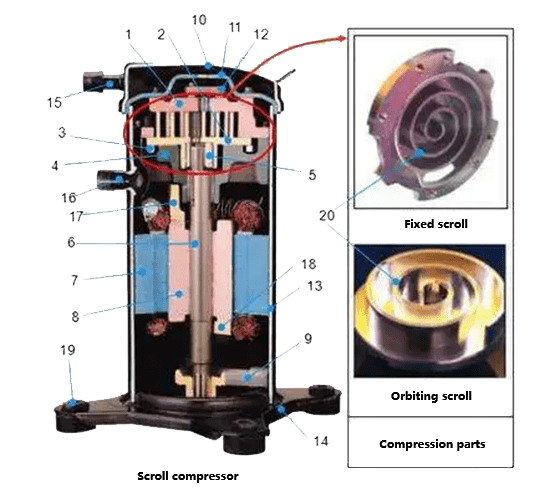

Figure 2: Scroll compressor diagram.

1.Fixed scroll 2. Orbiting scroll 3. Anti-rotation ring 4. Frame 5. Dynamic seal 6. Crankshaft 7. Stator 8. Rotor 9. Auxiliary structure 10. Outer cover 11. Discharge cover 12. Check valve 13. Housing 14. Base 15. Discharge port 16. Suction port 17. Upper balance weight 18. Lower balance weight 19. Support pad 20. Scroll body

2. How Does a Scroll Compressor Work?

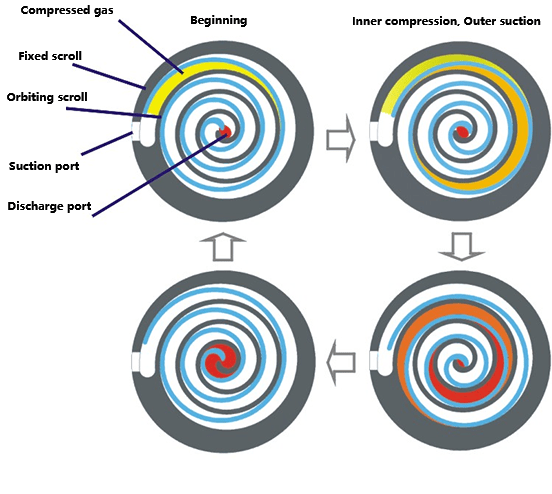

The operation of a scroll compressor can be broken down into three stages: suction, compression, and discharge.

Suction Stage

During the suction stage, the orbiting scroll moves away from the fixed scroll, creating a larger space between them. This creates a low-pressure zone at the inlet of the compressor, which allows the refrigerant gas to enter the compressor.

Compression Stage

As the orbiting scroll starts moving towards the fixed scroll, the pockets of gas trapped between them start to decrease in size. This reduces the volume of the gas and increases its pressure. The compression process continues until the pockets of gas reach the center of the scrolls.

Discharge Stage

At the center of the scrolls, the compressed gas is forced out of the compressor through the discharge port. The high-pressure gas then flows through the discharge line and into the condenser.

Figure 3: Scroll compressor working process.

3. Advantages of Scroll Compressors

High Efficiency

Scroll compressors are highly efficient compared to other types of compressors. This is because they have fewer moving parts, which reduces friction and energy losses. They also have a longer lifespan and require less maintenance, reducing operating costs.

Low Noise

Scroll compressors produce less noise than other types of compressors. This is because they operate at a lower RPM (Revolutions Per Minute) and have a smooth operation. They are therefore ideal for applications where noise levels need to be kept low, such as in residential air conditioning units.

High Reliability

Due to their simple design, scroll compressors are highly reliable and have a long lifespan. They are less prone to mechanical failure, reducing downtime and repair costs.

Compact Size

Scroll compressors are compact and lightweight compared to other types of compressors. This makes them ideal for use in small spaces or portable air conditioning units.

Figure 4: Digital scroll compressor diagram.

4. Disadvantages of Scroll Compressors

Despite their many advantages, scroll compressors have some disadvantages, including:

Cost

Scroll compressors can be more expensive than other types of compressors, such as reciprocating or rotary compressors.

Limited Capacity Range

Scroll compressors are best suited for low to medium capacity applications. For larger capacities, multiple scroll compressors may need to be used in parallel, which can add to the cost.

Sensitivity to Liquid Refrigerant

Scroll compressors are sensitive to liquid refrigerant, which can cause damage to the compressor if it enters the compression chamber.

Temperature Limitations

Scroll compressors are not suitable for very high-temperature applications, as they can experience thermal overload at high temperatures.

Maintenance

The design of scroll compressors can make them difficult to maintain and repair, especially if there is a problem with the compressor's internal components.

Limited Serviceability

Scroll compressors are often designed as sealed units, making them difficult to service or repair in the field.

5. Applications of Scroll Compressors

Air Conditioning

Scroll compressors are widely used in air conditioning systems, both in residential and commercial settings. They are preferred due to their high efficiency, low noise, and compact size.

Refrigeration

Scroll compressors are also used in refrigeration systems, such as refrigerators, freezers, and ice makers. They are preferred due to their reliability, low noise, and high efficiency.

Medical Applications

Scroll compressors are used in medical applications, such as oxygen concentrators and vacuum pumps. They are preferred due to their high reliability and low noise levels.

Figure 5: Copeland scroll compressor units.

6. Conclusion

In conclusion, a scroll compressor is a type of positive displacement compressor that uses two intermeshing spiral-shaped scrolls to compress the refrigerant gas. It operates through three stages: suction, compression, discharge.

Scroll compressors offer several advantages, including high efficiency, low noise, high reliability, and compact size. However, they also have some disadvantages, such as limited capacity and higher cost.

They are widely used in air conditioning, refrigeration, and medical applications. Overall, scroll compressors are an important component of many systems and offer a reliable and efficient solution for compressing gas.

Related Info

How to Add Oil to Semi-Hermetic Compressor: A Step-by-Step GuideWhat is a Hermetic Compressor? Understanding the Basics

Troubleshooting Air Conditioning Compressor: A Comprehensive Guide

Troubleshooting a Refrigerator Compressor Running But Not Cooling: A Comprehensive Guide

What is a Semi-Hermetic Compressor? Everything You Need to Know