In this article, we will have a comprehensive understanding of the types, structures, working principles, features and application ranges of condensers and evaporators.

1. Types of Condensers

Condensers can be divided into: air-cooled condensers, water-cooled condensers (shell and tube condensers, tube in tube condensers, shell and coil condensers, spiral plate condensers), evaporative condensers and spray condensers according to the cooling method.

1.1 Air-Cooled Condenser

Air-cooled condensers are often used in some small refrigeration and air conditioning devices such as refrigerators, freezers, small air conditioners, refrigerated trucks, and car air conditioners.

Advantages: No water required, simple installation.

Disadvantages: Small heat transfer coefficient, greatly affected by ambient temperature, difficult to remove dust, and only used in Freon refrigeration and air conditioning units.

According to the flow of air, air-cooled condensers can be divided into natural convection condensers and forced convection condensers.

1. Natural Convection Air-Cooled Condenser

(1) Components: copper tube (seamless steel tube) and copper clad steel wire.

(2) Features: no fan, reduced power consumption, low noise, low heat transfer coefficient.

2. Forced Convection Air-Cooled Condenser

Components: copper tube (seamless steel tube), fins and axial flow fan.

(3) Features: high power consumption, high noise, high heat transfer coefficient.

1.2 Water-Cooled Condenser

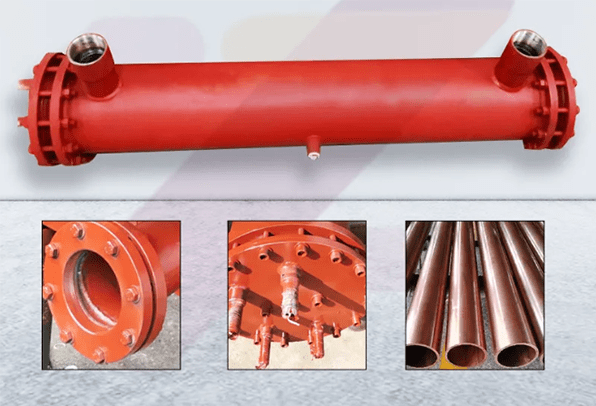

1. Shell and Tube Water-Cooled Condenser

1-Liquid outlet pipe; 2-Pressure gauge connector; 3-Gas inlet pipe; 4-Water distribution tank; 5-Safety valve connector; 6-Equalizer pipe; 7-Vent pipe

Vertical shell and tube condenser:

Features: high heat transfer coefficient, small footprint, easy to clean, large water consumption, bulky body.

Applicable to: large and medium-sized ammonia refrigeration systems.

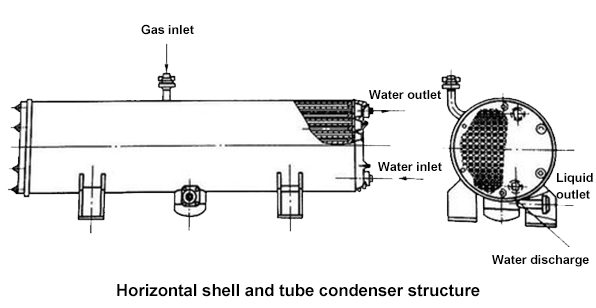

Horizontal shell and tube condenser:

Features: high heat transfer coefficient, low water consumption, high water quality requirements, difficult to clean.

Applicable to: Ammonia or Freon refrigeration system.

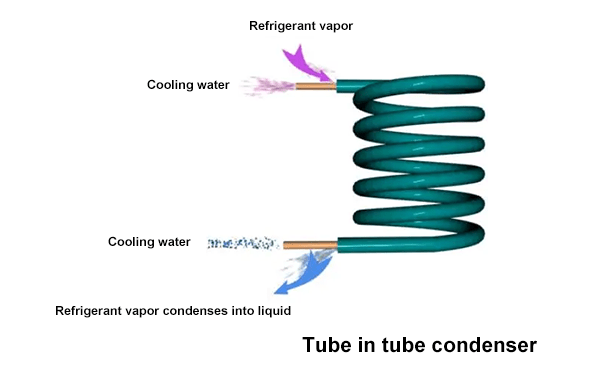

2. Tube in Tube Condenser

Features: high heat transfer coefficient, small unit footprint, simple structure, large metal consumption, difficult to clean, large water resistance.

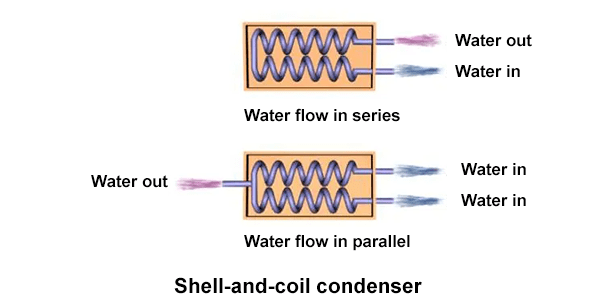

3. Shell and Coil Condenser

Features: simple structure, unable to be mechanically cleaned, strict water quality requirements, and regular chemical cleaning required.

4. Spiral Plate Condenser

Features: small size, light weight, high heat transfer coefficient, but not suitable for high pressure application, difficult to clean and repair inside, and strict water quality requirements.

1.3 Evaporative Condenser

Features: water saving, low cost, simple structure, easy to remove scale, small size.

1.4 Spray Condenser

Features: simple structure, easy to use, easy to remove scale, low water quality requirements, but large metal consumption, large footprint, and low heat transfer coefficient.

2. Types of Evaporators

1. Function:

The refrigerant liquid vaporizes in the evaporator to absorb the heat of the cooled medium to achieve the purpose of refrigeration / cooling.

2. Types:

According to the filling degree and evaporation condition of the evaporator, it can be divided into four types:

Dry evaporator, flooded evaporator, forced circulation evaporator, and spray evaporator (falling film evaporator).

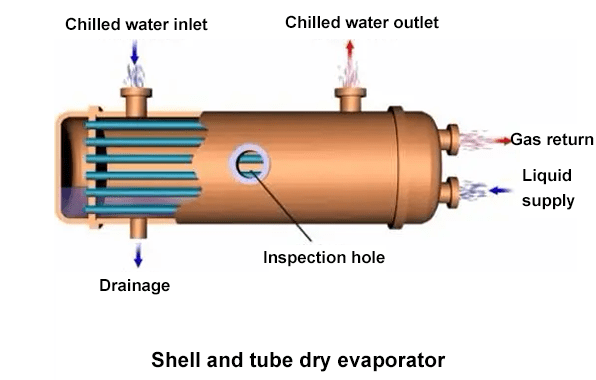

2.1 Dry Evaporator

1. Definition: An evaporator in which the refrigerant liquid is completely vaporized in the tube at one time.

2. Working principle diagram:

3. Application: Commonly used in cold storage or ice storage air conditioning.

4. Characteristics of dry evaporators

(1) Advantages: small amount of refrigerant liquid required, no need for a liquid receiver or a small one needed, easy to drain the lubricating oil in the evaporator back to the compressor, small cooling loss, and able to reduce the risk of freezing.

(2) Disadvantages: low heat transfer coefficient, poorer heat transfer effect compared to the flooded type.

5. Types:

According to the cooling object, it can be divided into: cooling liquid type (U-tube, straight tube, plate type), and cooling air type (bare tube evaporator, finned tube).

(1) U-tube dry evaporator

Advantages: The tube set can be pre-assembled, dirt on the outside of the tube can be removed and cleaned, thermal stress can be eliminated, the refrigerant is evenly distributed, and the heat transfer effect is good.

Disadvantages: Different molds are used when manufacturing the tube group, so it is difficult to replace the tube when it is damaged.

(2) Straight tube dry evaporator

Components: shell, tube, baffle, end cover, tube sheet, etc.;

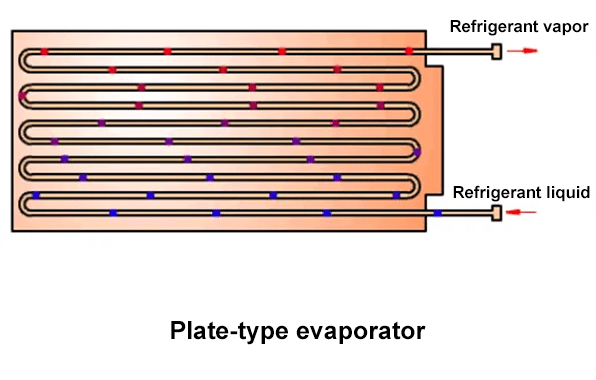

(3) Plate evaporator

Advantages: small resistance, compact structure, low metal consumption, adjustable heat transfer area, etc.

(4) Bare tube evaporator

(5) Finned tube evaporator

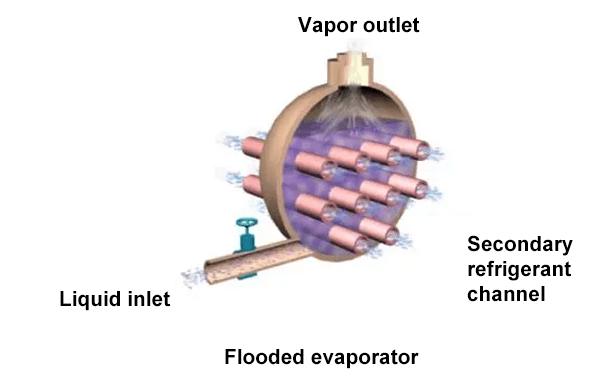

2.2 Flooded Evaporator

1. Working principle diagram:

2. Features:

Compact structure, good heat transfer effect, easy to install, easy to use; but large refrigerant filling volume, slightly higher evaporation temperature at the bottom, which reduces the heat transfer temperature difference. For Freon evaporators, lubricating oil is difficult to discharge and the refrigerant is prone to freezing.

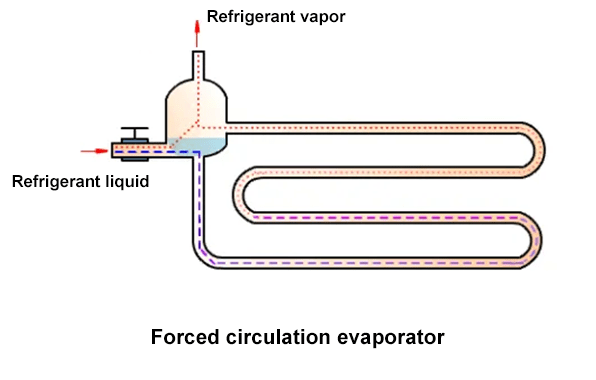

2.3 Forced Circulation Evaporator

1. Definition:

An evaporator in which the refrigerant liquid needs to be circulated several times before it can be completely vaporized.

2. Working principle diagram:

3. Features:

High heat transfer coefficient, but large size, large amount of refrigerant required, and high operating costs.

2.4 Spray Evaporator

Features: Use a pump to spray the working fluid on the heat transfer surface. High boiling heat release coefficient, small working fluid filling volume, able to eliminate the influence of static liquid height on evaporation temperature, but high equipment cost.

2.5 Other Types of Evaporators

1. Air cooler: An evaporator that cools forced air.

2. Vertical tube and cold water tank type evaporator: