The condenser is one of the main heat exchange equipment in refrigeration units. Its task is to cool and condense the high-pressure superheated refrigerant vapor discharged from the compressor into a saturated liquid or even a supercooled liquid by releasing heat to the ambient medium.

According to the different cooling media and cooling methods used by the condenser, there are mainly three types of condensers:

● Air cooled type

● Water cooled type

● Evaporative type

1. Water-Cooled Condenser

This type of condenser uses water as a cooling medium to take away the heat released when the refrigerant condenses. The cooling water can be used once or recycled.

When using circulating water, a cooling tower or cold water pool must be equipped to ensure that the water is continuously cooled. According to its structure, there are mainly shell and tube type, tube in tube type, and plate type that is now commonly used.

1.1 Shell and Tube Condenser

According to different refrigerants used in the refrigeration unit, the structural characteristics of condensers are also different. Generally, vertical shell and tube condensers are suitable for large ammonia refrigeration units, while horizontal shell and tube condensers are commonly used in large and medium-sized ammonia or Freon refrigeration units.

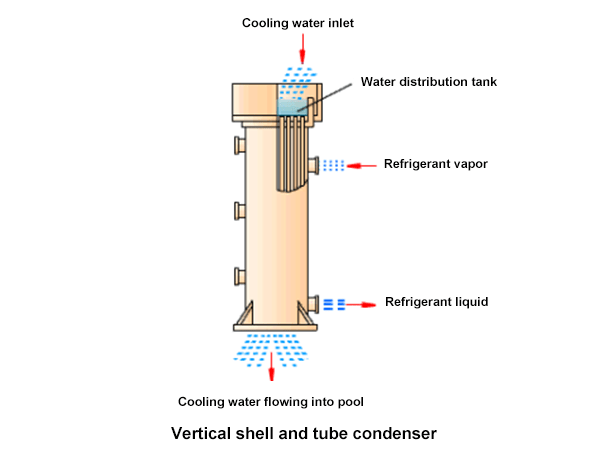

(1) Vertical Shell and Tube Condenser

The main features of vertical shell and tube condenser are:

● Thanks to the high cooling water flow rate and high flow velocity, the heat transfer coefficient is relatively high, generally K=600~700 (kcal/m2/h/℃).

● Vertical installation occupies a small area.

● The cooling water flows directly and has a high flow rate, so the water quality requirements are not high, and general water sources can be used as cooling water.

● The scale in the tube is easy to remove, and there is no need to stop the refrigeration system.

● Because the cooling water temperature rise in the vertical condenser is generally only 2~4℃, and the logarithmic mean temperature difference is generally around 5~6℃, the water consumption is relatively large.

(2) Horizontal Shell and Tube Condenser

It has a similar shell structure to the vertical condenser, and the main difference is the horizontal placement of the shell and the multi-path flow of water.

Features of horizontal shell and tube condenser:

● High heat transfer coefficient, low cooling water consumption, easy operation and management;

● High requirements for cooling water quality.

● This device is currently widely used in large and medium-sized refrigeration devices.

1.2 Tube in Tube Condenser

It is a water-cooled condenser made of tubes of different diameters, which are sheathed together and bent into a spiral or serpentine shape. As shown in the figure, the refrigerant vapor condenses in the tube, and the condensate is drawn out from the bottom. The cooling water flows from bottom to top in the tube with a smaller diameter, which is countercurrent with the refrigerant, so the heat transfer effect is better.

1.3 Plate Condenser

The plate condenser is composed of a group of stainless steel corrugated plates connected in series, forming cold and hot fluid channels on both sides of the heat transfer plate, and heat is exchanged through the plate wall during the flowing process.

The thickness of the heat exchange plate is about 0.5mm, and the plate spacing is generally 2-5mm.

Features of plate heat exchanger:

Plate heat exchangers feature small size, light weight, high heat transfer efficiency, less refrigerant filling required, and high reliability, and have been widely used in recent years.

However, its internal volume is small, and the condensed liquid refrigerant should be removed in time. It has high requirements for cooling water quality and is difficult to clean. Besides, the internal leakage is not easy to repair.

2. Air-Cooled Condenser

This condenser uses air as the cooling medium. The refrigerant condenses in the tube, and the air flows outside the tube to absorb the heat released by the refrigerant vapor in the tube. Due to the small heat transfer coefficient of air, fins are often set outside the tube (air side) to enhance the heat transfer.

Air-cooled condenser is divided into:

● Natural convection air-cooled condenser

● Forced convection air-cooled condenser

2.1 Natural Convection Air-Cooled Condenser

The air convection of this condenser relies on thermal pressure. There is no fan and no fan noise. The condenser features simple structure, low failure rate, but low heat transfer efficiency, usually used in refrigeration devices with very small cooling capacity, such as household refrigerators, etc.

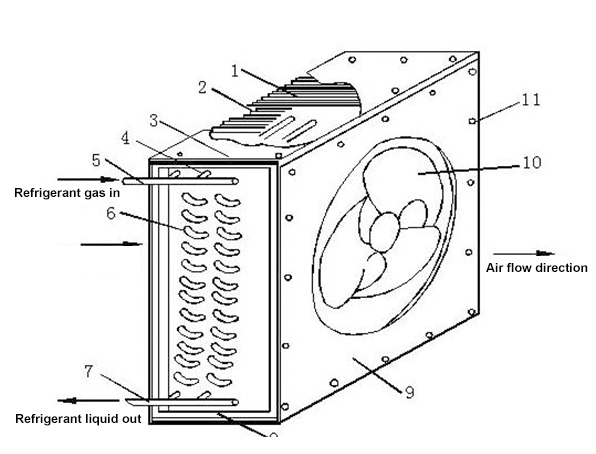

2.2 Forced Convection Air-Cooled Condenser

Forced convection condensers have fan noise, but high heat transfer efficiency, easy use, no water source required, and wide application. Home air conditioning systems use this type of condenser for heat exchange.

It consists of several groups of serpentine coils with fins on the outside. An axial fan is set on one side of the coil group.

Comparison between air-cooled condensers and water-cooled condensers:

① The initial investment and operating costs of water-cooled equipment are lower than those of air-cooled equipment in places with sufficient cooling water;

② Due to the high outdoor air temperature in summer, the condensation temperature can generally reach 50°C. In order to obtain the same cooling capacity, the capacity of the refrigeration compressor of the air-cooled equipment needs to be increased by about 15%;

③ The refrigeration equipment system using air-cooled condensers is simple in composition and can alleviate water shortage.

3. Evaporative Condenser

The heat exchange of an evaporative condenser is mainly through the cooling water evaporating in the air to absorb the latent heat of vaporization. According to the air flow mode, it can be divided into forced-draft and induced-draft types.

The evaporative condenser consists of a cooling tube set, water supply equipment, ventilator, water baffle and box. The cooling tube set is a serpentine coil set made of seamless steel pipes and installed in a rectangular box made of thin steel plates. A fan is installed on both sides or one side or the top of the box, and the bottom of the box also serves as a cooling water circulation pool.

Features of evaporative condensers:

① The condensation heat is taken away by water vaporization, and the cooling water consumption is small;

② The wet-bulb temperature of the inlet air of the evaporative condenser has a great influence on the heat exchange. For the same condensation temperature and air volume, the lower the inlet wet-bulb temperature, the greater the evaporation of cooling water and the better the condensation effect;

③ The evaporative condenser consumes less water, and the required air volume is less than 1/2 of the air-cooled type, so it is particularly suitable for dry and water-scarce areas.