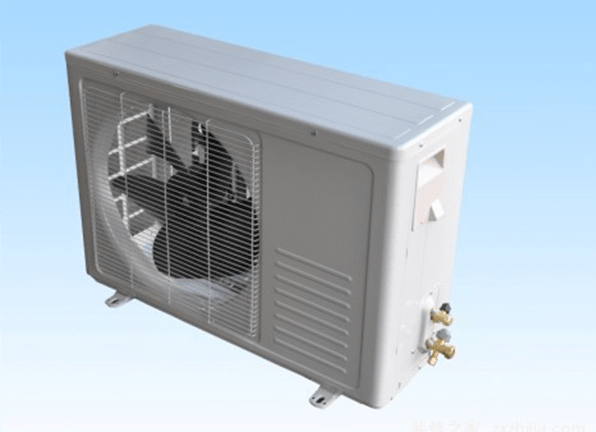

Figure 1: Air condition compressor.

The air conditioner mainly relies on the work of the air conditioner compressor (AC compressor) to achieve the cooling cycle. The air conditioner compressor, generally installed on the outdoor unit, is the heart of the air conditioner and determines the cooling effect of the air conditioner. It is very necessary for us to know more about the air-conditioning compressor, which is an essential air-conditioning component.

1. Air Conditioning System Components

Before explaining the working principle of the air-conditioning compressor, it is necessary to understand the composition of the air-conditioning cooling system. The air conditioning system is composed of four main components: compressor, condenser, throttling device and evaporator. These four components are the most critical and basic components of the air conditioning system.

Figure 2: Air conditioning system components diagram.

1. Compressor: It absorbs refrigerant vapor (refrigerant evaporated by the evaporator), then compresses, and discharges the refrigerant vapor after compression.

2. Condenser: It makes the high-temperature and high-pressure gaseous refrigerant discharged from the compressor dissipate its heat through the convection of air or water and condense into a high-pressure liquid refrigerant.

3. Evaporator: It evaporates the liquid refrigerant decompressed by the capillary tube (expansion valve) to absorb the heat of the air around the evaporator. This part of the air with low temperature is blown into the room through the centrifugal fan, so that the indoor temperature will drop to achieve the purpose of indoor cooling.

4. Capillary tube: The length and thickness of the capillary tube directly affects the evaporation temperature of the evaporator, and its function is to limit the flow and reduce pressure. It is generally installed in the outdoor unit, but the indoor unit of the cabinet air conditioner also has one.

5. Solenoid valve: According to the instructions sent by any temperature sensing element or pressure sensing element, it cuts off the flow of refrigerant in the liquid pipeline, suction pipeline or discharge pipeline.

6. Four-way valve / electromagnetic reversing valve: used to change the refrigerant flow direction when switching between the heat pump system and the cooling system.

7. Thermostat: It controls the start and stop of the compressor according to the indoor temperature. When the indoor temperature is higher than the set value, the thermostat can connect the circuit and start the air conditioner to run.

8. Defrost controller: There are many ways to defrost the outdoor heat exchanger, mainly including water flushing, electric heating element heating and hot air circulation heating, etc.

9. Overload protector: When the heat load in the air-conditioning room is too large, the ambient temperature is too high, the heat dissipation effect of the outdoor condenser is poor, the compressor cylinder is stuck, or the electrical circuit is short-circuited, the air conditioner compressor can be overloaded, and the compressor motor is easy to be burned out. Therefore, an overload protector is installed in the air conditioner to prevent the motor of the air conditioner from being burned out due to overload.

Figure 3: Air conditioner outdoor unit.

10. Run capacitor: It is mainly used to reduce the running current and improve the power factor of the motor.

11. Pressure controller: It is an electrical switch controlled by a pressure signal. When the discharge pressure of the compressor in the air conditioner exceeds the set value or the suction pressure is lower than the set value, the contacts of the pressure controller cut off the power supply, so that the compressor stops working, which plays the role of protection and automatic control.

12. Remote control: It consists of two parts: an infrared transmitter and an infrared remote control receiver.

13. Fan: It exchanges heat with the heat exchanger through air convection. The air conditioner uses several kinds of fans, the indoor unit of the cabinet unit uses a centrifugal fan, the indoor unit of the hanging unit uses a cross-flow fan, and the outdoor unit of the split unit uses an axial fan; the window unit also uses an axial fan.

14. Fan motor: It is a single-phase or three-phase asynchronous motor, requiring the characteristics of smooth running, little vibration and low noise.

15. Air filter: a fine mesh shape made of various fiber materials. Indoor air first passes through the air filter to remove dust and then enters the evaporator for heat exchange.

1.1 Common AC Compressor Types

Air conditioning compressors currently used mainly include

·Piston (reciprocating) compressor

·Rotary compressor

·Scroll compressor

·Screw compressor

From the perspective of AC compressor structure, air conditioner compressors can be divided into

·Open type,

·Semi-hermetic type

·Fully hermetic type

The compressor of the small air conditioner is usually a hermetic compressor, such as rotary compressor and scroll compressor.

Figure 4: Rotary compressor.

2. Working Process and Principle of Air Conditioning Compressor

The compressor is the heart of the refrigeration and air conditioning system. Whether it is an air conditioner, cold storage, chemical refrigeration process and other working conditions, a compressor, as an important component, must be needed.

How does a AC compressor compress gas? Simply put, the gas compression and delivery process is completed by changing the volume of the gas. Any power equipment needs a prime mover to do the work, and as the same the compressor needs an electric motor to drive itself.

Before understanding the working principle of the air conditioner compressor, first understand the working circuit of the AC compressor. The working circuit of the AC compressor is divided into an evaporation area (low pressure area) and a condensation area (high pressure area). The air conditioner compressor plays the role of compressing and driving the refrigerant in the air conditioner cooling circuit.

When the air conditioner is cooling, the AC compressor draws the refrigerant from the low-pressure area, compresses it, and sends it to the high-pressure area for cooling and condensation. The heat is released into the air through the heat sink, and the refrigerant also changes from gaseous to liquid.

The refrigerant then flows from the high-pressure area to the low-pressure area, and is sent into the evaporator through the capillary tube. As the pressure drops suddenly, the liquid refrigerant immediately becomes gaseous, and absorbs a large amount of heat in the air through the heat sink. In the above way, the cycle is repeated to complete the cooling. The heating system is roughly the same principle, but in the opposite way.

Figure 5: Working principle diagram of air conditioner compressor.

Generally speaking, the working principle of the AC compressor can be summarized as follows: when the air conditioner compressor is working, the refrigerant continuously absorbs the heat at one end of the low-pressure area and then the heat is sent to the high-pressure area to dissipate into the air, continuously adjusting the temperature.

3. Functions of Compressors in Air Conditioning Systems

The function of the air conditioner compressor is to compress and drive the refrigerant in the air conditioner refrigerant circuit. The air conditioner compressor is generally installed in the outdoor unit. Its role is mainly manifested in the following points:

(1) The air conditioner compressor absorbs refrigerant vapor from the evaporator to ensure a certain evaporation pressure in the evaporator;

(2) The air conditioner compressor increases the pressure (compression pressure) of refrigerant vapor to create conditions for condensation at higher temperatures;

(3) The air conditioner compressor can convey the refrigerant, and then make it complete the cooling cycle.

4. Common Faults and Repairs of Air-Conditioning Compressors

4.1 Common Air Conditioning Compressor Faults

1. Refrigerant leakage: Refrigerant leakage is the most common problem in air conditioning compressor systems.

2. The AC compressor has an abnormal sound (air conditioner compressor buzzing noise). There are many reasons for the abnormal sound of the air conditioner compressor. For example, the electromagnetic clutch of the air conditioner compressor is damaged, or the internal wear of the compressor is serious, etc., which can cause abnormal noise.

3. Vibration and noise of the compressor: This kind of problem often occurs in maintenance work. Generally, it does not have much impact on the cooling performance, but it will make the user feel uncomfortable. This is often caused by the collision between the pipe and the casing, the loose fixing bolts of the compressor, and the shock absorber falling off.

4. The AC compressor does not work. There are many reasons why the compressor does not work, usually because of related circuit problems. It is possible to preliminarily check whether the compressor is damaged by directly supplying power to the electromagnetic clutch of the compressor.

5.The AC compressor is jammed. If the compressor is not lubricated enough or there are impurities entering in the system, it will often cause the compressor to be stuck. The fault phenomenon is that the compressor does not run after power-on, and the protector operates.

6. The suction and discharge valves of the AC compressor are not closed tightly. If the suction and discharge valves of the compressor are damaged, even if the refrigerant is sufficient, the system cannot establish high and low pressure or it is difficult to establish a qualified high and low pressure, and the system does not cool or the cooling effect is very poor.

Figure 6: Severely worn compressor scrolls.

4.2 Air Conditioning Compressor Fault Repair Methods

If the motor part of the AC compressor has a problem, the suction and discharge valves of the compressor are not closed tightly, or the thermal protector is faulty, the corresponding parts or the compressor should be replaced. If you encounter the stuck compressor problem, you can first try to repair it. The specific methods are as follows:

(1) Tapping method:

After starting up, tap the lower half of the compressor with a wooden hammer to make the stuck parts inside the compressor vibrate and start running.

(2) Capacitor starting method:

A capacitor with a larger electrical capacity than the original can be connected to the circuit to start the compressor.

(3) High voltage starting method:

A regulator can be used to turn up the power supply voltage to start the compressor.

(4) Pressure relief method:

Start the AC compressor after all the refrigerant in the system is discharged.

If none of the above methods work, the only option is to replace the air conditioner compressor. Note: If you lack relevant maintenance knowledge of compressors, please do not repair or replace the damaged compressor yourself, and it is a better choice to seek professional help.

5. FAQs

5.1 Does the AC Compressor Compress Gas or Liquid?

Gas. The high-temperature and high-pressure gas comes out of the compressor, and then goes to the condenser to dissipate heat and become a liquid. The refrigerant liquid then evaporates in the evaporator, absorbs heat and cools, turns into gas and is sucked into the compressor.

5.2 How Much is an Air Conditioner Compressor? (air conditioner compressor cost)

About $200-$3,000. The air conditioner compressor is the core part of the air conditioner, and its price depends on the brand and type of the compressor. Generally, the price of a household air conditioner compressor is around $200-$3,000.

5.3 How Much Does It Cost to Replace a Compressor in an Air Conditioner?

About $400-$4,000. The cost of replacing an air conditioner compressor, based on a single compressor, plus labor and installation costs, generally ranges from $400 to $4,000. In addition, depending on the type of air conditioner and the position of the installation, there may be some price fluctuations.

5.4 How to Tell If an Air Conditioner Compressor is Bad?

Signs of a bad air conditioner compressor include:

· Strange noises from external devices

· System overheating

· Lukewarm air blown from vents

· Water leaking of HVAC system components

· Dirty condenser coils

·High electricity bills

5.5 How Long Should an Air Conditioner Compressor Last?

About 10 years.

Generally, the service life of air conditioner products is about 10 years. Beyond this period, the air conditioner is prone to problems such as loud noise, increased power consumption, decreased cooling capacity, and severe odor at the air outlet. At the same time, due to long-term exposure to the outdoors, the bracket of the external unit is prone to corrosion, rust, looseness and bending, which poses certain safety hazards.

P1 = P2 + F

P1: The pressure generated by the filling medium (refrigerant) in the sensing bulb, acting on the top of the diaphragm;

P2: Evaporating pressure (for internally equalized type, it is the evaporator inlet pressure, and for externally equalized type, it is the evaporator outlet pressure), acting under the diaphragm;

F: Spring force, acting below the diaphragm.

When the temperature of the sensing bulb decreases, P1

Note: other forces, such as diaphragm stiffness, frictional resistance of transmission parts, fluid force on the valve core, etc., are not considered in the analysis.

3. Functions of Thermal Expansion Valve

Thermal expansion valves are widely used in refrigerators, air conditioners, central air-conditioning chillers, and HVAC systems. In the refrigeration system, thermal expansion valve, for example AC thermal expansion valve (thermal expansion valve air conditioning), is installed on the evaporator inlet, which has three functions:

Figure 7: Throttling function of thermal expansion valve in refrigeration system.

① Throttling and depressurization

The high-temperature and high-pressure refrigerant condensed by the condenser is throttled and depressurized, and becomes a low-temperature and low-pressure gas-liquid mixture that is easy to evaporate. It enters the evaporator to evaporate, and absorbs external heat.

② Flow adjusting

According to the temperature signal obtained by the sensing bulb or the power head, the expansion valve can automatically adjust the refrigerant flow into the evaporator to meet the changing needs of the cooling load.

③ Maintaining a certain degree of superheat, preventing liquid slugging and abnormal overheating

The expansion valve make the evaporator have a certain degree of superheat by adjusting the flow rate, ensures the effective use of the total volume of the evaporator, and avoids liquid refrigerant entering the compressor to cause liquid slugging; at the same time, it can control the degree of superheat within a certain range to prevent abnormal overheating.

4. How Do You Know if a TXV Valve is Bad? (Bad Thermal Expansion Valve Symptoms)

Common failure phenomena of thermal expansion valves include the following three aspects.

·Failure symptom 1: The refrigerant flow rate provided by the thermal expansion valve is insufficient (small opening).

·Symptom 2: The refrigerant flow rate provided by the expansion valve is too large (large opening).

·Symptom 3: The expansion valve sometimes supplies insufficient refrigerant liquid, and sometimes supplies too much (fluctuation).

4.1 Symptom 1: Insufficient Refrigerant

【Reason】:

1): Ice blockage. If there is a lot of water in the refrigerant, when the evaporation temperature drops below 0°C, it may freeze at the throttling port of the thermal expansion valve, resulting in "ice blockage".

Figure 8: Frosting on the outside of the thermal expansion valve.

2) : Dirty blockage. There are impurities in the system. The sources of impurities in the refrigeration system include: the oxide film that was not removed during the welding of the copper tube, the metal fines produced by the wear and tear of the compressor operation, and the substances produced by the chemical reaction of the refrigeration oil.

3) : Filling medium leakage of the sensing bulb.

4) : Incorrect installation position of the sensing bulb.

5) : The sensing bulb fails to feel the accurate temperature.

Reason 6: Filling medium migration (with MOP function)

6) : The valve core is stuck.

7) : The capacity of the selected expansion valve is too small, and the superheat degree is not adjusted properly.

4.2 Symptom 2: Too Large Refrigerant Flow Rate

【Reason】:

1) The valve core of the thermal expansion valve is stuck.

2) The external equalizer line is blocked. The sensed pressure cannot be quickly transmitted to the diaphragm underneath, resulting in a small valve closing force and a large opening of the valve port.

3) There is a problem with the installation of the sensing bulb. If the installation location and method are wrong, or the contact is not good, and the heat preservation is not good, it may cause too much liquid supply.

4) The cooling capacity of the selected expansion valve is too large.

5) Improper adjustment of superheat degree of thermal expansion valve.

4.3 Symptom 3: Refrigerant Flow Rate Fluctuation

【Reason】:

1) The cooling capacity of the selected expansion valve is too large to cause fluctuations.

2) The installation position of the temperature sensing bulb is inappropriate.

3) Uneven dispensing of liquid from the dispensing head.

Related Info

Functions and Types of Condensers in Refrigeration SystemWhat is Refrigeration Cycle? The Refrigeration Cycle Explained

What is a scroll compressor? Everything You Need to Know

Thermal Expansion Valve (TXV): Everything You Need To Know

How Water Source Heat Pumps Work