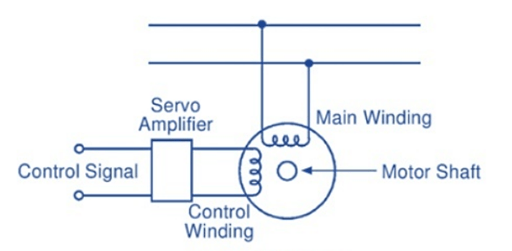

Most servo motors used in servos are AC motors. Figure 1 shows a circuit diagram of an AC servo motor. This article will introduce the construction, working principle, features of AC servo motors.

Figure 1: AC servo motor circuit diagram.

1. Composition of AC Servo Motor

The structure of an AC servo motor is similar to that of an ordinary induction motor, which consists of a stator and a rotor.

1.1 AC Servo Motor Stator

The structure of the AC servo motor stator is basically similar to that of the capacitor split-phase single-phase asynchronous motor, as shown in Figure 2. Its stator is equipped with two windings whose positions are different from each other by 90°. One is the excitation winding f, which is always connected to the AC voltage Uf, AND the other is the control winding C, which is connected to the control signal voltage Uc.

Figure 2: Schematic diagram of AC servo motor.

1.2 AC Servo Motor Rotor

The rotor of the AC servo motor is usually made into a squirrel cage type. In order to make the servo motor have a wide speed regulation range, linear mechanical characteristics, no "self-rotation" phenomenon and fast response performance, it should have two characteristics of large rotor resistance and small rotational inertia compared with ordinary motor.

At present, there are two types of rotor structures: one is a squirrel-cage rotor with high-resistivity bars. In order to reduce the rotor's moment of inertia, the rotor is made slender.

The other is a hollow cup rotor made of aluminum alloy. The cup wall is very thin, only 0.2-0.3mm. In order to reduce the magnetic resistance of the magnetic circuit, a fixed inner stator should be placed in the hollow cup rotor, as shown in Figure 3. The hollow cup rotor is widely used because of its small moment of inertia, rapid response and smooth operation.

Figure 3: Cross section of a two-phase servo motor with drag-cup rotor.

To minimize rotor kinetic energy, the servo motor is wound with as many poles as possible to allow it to operate at low speeds, which increases torque accordingly. AC servo motors have a small air gap to reduce magnetizing current and subsequent losses.

2. How AC Servo Motors Work

When the AC servo motor has no control voltage, there is only the pulsating magnetic field generated by the excitation winding in the stator, and the rotor is stationary. When there is a control voltage, a rotating magnetic field is generated in the stator.

As the magnetic field sweeps across the rotor, an electromotive force is induced in the rotor conductors, and then the induced current forms a closed path. The rotating magnetic field interacts with these currents, creating torque on the rotor in the direction of the magnetic field rotation.

When the load is constant, the speed of the motor changes with the size of the control voltage. When the phase of the control voltage is opposite, the servo motor will reverse.

There is no essential difference between the working principle of an AC servo motor and a single-phase induction motor. However, the AC servo motor must have a performance that can overcome the so-called "self-rotation" phenomenon of the AC servo motor, that is, when there is no control signal, it should not rotate. Especially when it is rotating, if the control signal disappears, it can stop rotating immediately. In contrast, after the ordinary induction motor rotates, if the control signal disappears, it often continues to rotate.

3. Features of AC Servo Motors

Although the working principle of an AC servo motor is similar to that of a single-phase asynchronous motor, the rotor resistance of the former is much larger than that of the latter. Therefore, compared with the single-phase asynchronous motor, the servo motor has the following three remarkable characteristics:

3.1 Large Starting Torque

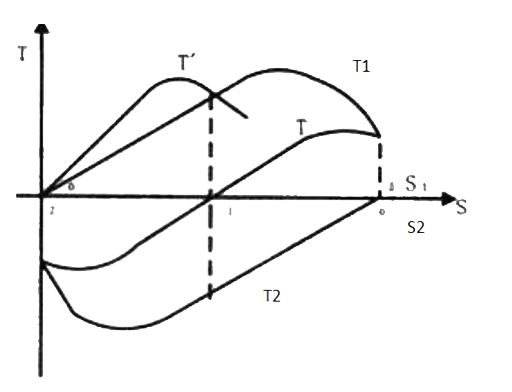

Due to the large rotor resistance, the torque characteristic curve of the AC servo motor is shown as curve 1 in Figure 4, which is significantly different from the torque characteristic curve 2 of the ordinary asynchronous motor.

It can make the critical slip ratio S0>1, which not only makes the torque characteristic (mechanical characteristic) curve closer to linear, but also has a larger starting torque. Therefore, when the stator has a control voltage, the rotor rotates immediately, that is, it has the characteristics of fast starting and high sensitivity.

Figure 4: Torque characteristic curve of the servo motor.

3.2 Wide Operating Range

As shown in Fig. 4, the servo motor can operate stably when the slip ratio S is in the range of 0 to 1.

3.3 No Self-rotation Phenomenon

When the servo motor is in normal operation, as long as the control voltage is lost, the motor will stop running immediately. When the servo motor loses the control voltage, it is in a single-phase operation state.

Due to the large rotor resistance, two rotating magnetic fields rotating in opposite directions in the stator interact with the rotor to generate two torque characteristic curves (T1-S1, T2-S2 curves). T1-S1, T2-S2 curves and the resultant torque characteristic curve (T-S curve), shown in Figure 5, are different from the torque characteristic curve T'-S of an ordinary single-phase asynchronous motor.

The resultant torque T at this time is the braking torque, thereby quickly stopping the motor.

Figure 5: Torque characteristic curve of servo motor in single-phase operation.

Fig. 6 is the mechanical characteristic curve when the servo motor runs in a single phase. When the load is constant, the higher the control voltage Uc is, and the higher the speed is . When the control voltage is constant, as the load increases, the speed decreases.

Figure 6: Mechanical characteristic curve of the servo motor.

4. Torque Speed Characteristics of AC Servo Motors

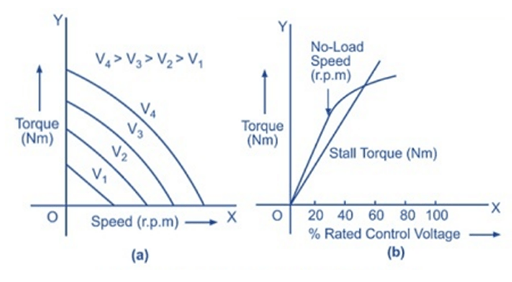

The general shape of the torque-speed characteristic of an induction motor depends heavily on the rotor resistance value (Figure 7). Increasing the rotor resistance can linearize the speed-torque characteristic curve. The rotor of a servo motor has high resistance, so its torque-speed characteristic is close to linear.

Figure 7: Variation of torque-speed characteristic curve of induction motors with rotor resistance.

Figure 8(a) shows the torque-speed characteristics of the servo motor under various control voltages (V14, etc.). It can be observed that servo motor torque (especially stall or starting torque) varies almost linearly with speed and control voltage.

In the zero-speed range, the torque of any given control voltage value is very high and the torque decreases as the motor accelerates. The reduction in torque is used as a stability characteristic of the control system.

Figure 8(b) shows the relationship between no-load speed, stall torque, and control voltage (stationary-phase voltage is constant).

Figure 8: (a) Typical torque-speed characteristic curve of servo motor (ac) under different control voltages, and (b) no-load speed, stall torque and control-voltage curves.

4.1 Other Performance Characteristics of AC Servo Motors

Figure 9 illustrates some additional performance characteristics of a typical AC servo motor.

Figure 9: Performance characteristics of a typical AC servo motor.

The output power of an AC servo motor is generally 0.1-100W. When the power frequency is 50Hz, the voltages can be 36V, 110V, 220V, or 380V; when the power frequency is 400Hz, the voltages can be 20V, 26V, 36V, 115V and so on.

The AC servo motor runs smoothly and has low noise. However, the control characteristics are non-linear, and due to the large rotor resistance, large loss and low efficiency, it is large and heavy compared with the DC servo motor of the same capacity.

Related Info

Three Control Methods of Servo MotorServo Motors: Construction, Types, Advantages & Applications

What is Positive Displacement Pump?

Positive Displacement Pump vs Centrifugal Pump

Servo Motor: Basics, Work Principle & Selection