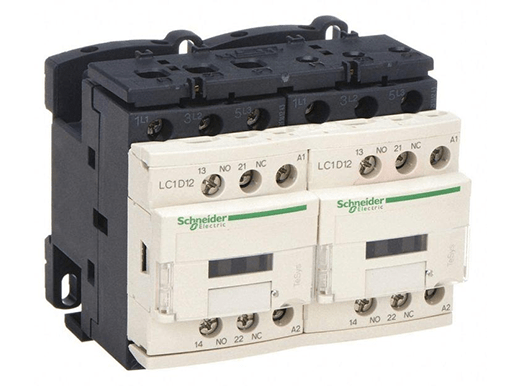

Figure 1: An AC contactor in operation.

In many cases, the magnetic contactor is simply referred to as a contactor. It is an electrical appliance that uses the current flowing through the coil to generate a magnetic field to close the contacts to control the load in industrial electricity. The circuit that controls the contactor usually has a much lower power level than the switched circuit. For example, a 230-volt motor switch may be controlled by a 24-volt coil electromagnet.

1. Basics about the Magnetic Contactor

In industrial electrical, there are many types of magnetic contactors, with the current ranging from 5A to 1000A, and their uses are quite extensive. In electrical engineering, a magnetic contactor is an automatic switcher that is used to connect or disconnect an AC/DC main circuit or a large-capacity control circuit with a load. Its main control object is the motor.

In addition, it is also used for other electrical loads, such as electric heaters, welding machines, lighting equipment. The contactor can not only make and cut the circuit, but also has the function of low voltage release protection. The contactor has a large control capacity and is suitable for frequent operation and remote control. It is one of the important components in the automatic control system.

2. Constitution of a Magnetic Contactor

The contactor is composed of magnetic system (armature, fixed iron core, magnetic coil), contact system (normally open contact and normally closed contact) and arc extinguishing device.

Figure 2: Schneider Electric 24VDC IEC Magnetic Contactor.

2.1 Magnetic Mechanism

The magnetic mechanism is one of the most important parts of a magnetic contactor, including a moving iron core, a fixed iron core and coil. The coil is powered to generate electromagnetic force to drive the contact.

As their names indicate, in operation, the coil and the fixed iron core don’t move while the moving iron core slides into the fixed iron core.

2.2 Contacts

There are several types of contacts and can be divided into the main contact and the auxiliary contact. There are also normally open (NO) contact and normally close (NC) contact.

2.3 Arc Extinguishing Devices

The arc extinguishing cover is a simple insulating and high temperature arc extinguishing device made of clay and asbestos cement. In the arc extinguishing cover, the longitudinal joint method is generally applied.

2.4 Other Parts

Other components include reaction spring, buffer spring, transmission mechanism and shell, etc.

Figure 3: The components of a magnetic contactor.

3. Working Principles of a Magnetic Contactor

When the coil of the contactor is energized, a strong magnetic field will be generated, which will cause the fixed iron core to generate magnetic force to attract the moving iron core and drive the contacts to move. The NC contact is disconnected and the NO contact is closed, and the two are linked.

When de-energized, the magnetic force disappears. The moving iron core releases under the action of the release spring, making the contact back to its place. The NC contact is closed and the NO contact is open.

Related Info

Top 3 Things you must Know about Circuit BreakerHow do Circuit Breakers Extinguish Electric Arc?

Top Circuit Breaker Brands

What are the Main Parameters of a Molded Case Circuit Breaker?

How to Calculate the Breaking Capacity?