What are the main faults of the compressor How to replace it if it is broken 1. Analysis of the main faults and causes of the compressor 1. Stalling (stuck): The compressor does not move and emits a "buzzing" sound: Foreign matter enters, moving parts such as crankshaft, piston, cylinder are stuck; High and low pressure side pressure imbalance; Motor burnout; The voltage is too low; The compressor runs short of oil or overload, and the mechanical parts are worn down; Oil degradation, mechanical parts are severely worn; During low temperature heating, the compressor temperature is too low; Compressor capacitor damage or attenuation; Defective rotor clearance. 2. The compressor can operate, but the discharge pressure is low: Compressor suction liquid; condenser failure; Protector action; The pipeline resistance is large. 3. The compressor can be operated, but it stops due to the gradual increase of current: Protector action; Inspiratory pressure is too high; The mechanical part of the compressor is damaged; 4. Compressor overcurrent: Two devices failure; The refrigeration system is blocked; Overload operation (refrigerant volume, voltage); Fan motor speed (capacitance attenuation, fan failure); Inverter should pay special attention to the failure of electric control. The three cameras run out of phase and the winding is burnt. When using an external overload protector, use a multimeter to measure whether the overload protector is conducting. Normally, it is conducting. 5、Noisy: When the compressor is started, within 3 to 5 minutes, due to the unstable system, there will be a loud sound; Pipe vibration sound, motor and fan blade sound, sheet metal resonance sound; When air is mixed in the system, there will be airflow sound; When there are impurities or copper shavings in the system, the metal will hit the valve blade sound; Poor rotor clearance; Lack of refrigeration oil; Liquid refrigerant enters the compressor and produces liquid compression; 6. The valve piece is broken (no suction and exhaust capacity, high and low pressure series gas): The valve disc has a large gap and is stuck (rotor type); Crankshaft is broken, no rotation; spring break; Compressor oil shortage, excessive valve plate wear; Foreign matter enters the compressor cylinder; Four-way valve series gas; Lack of refrigerant; Three-phase power supply, reverse power supply will cause compressor to reverse; Excessive water content, causing ice blockage. 7. Large winding current: Whether the other parts of the system (mainly the motor and electric control) work normally; Stator burnout (coil short circuit, overload, phase loss operation, refrigerant leakage); Too much refrigerant charge will cause high power; Is the system likely to be clogged, resulting in a situation where the high pressure is too high and the low pressure is too low; Whether the capacitance is normal; The ambient temperature is too high;

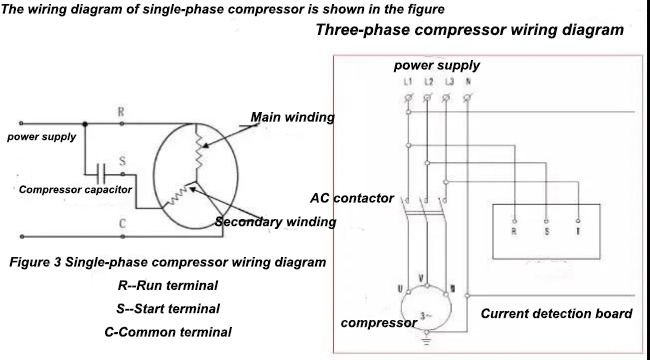

Second, the steps and points of attention for compressor replacement 1. Refrigerant: pay attention to the ventilation of the working environment, the speed of the refrigerant should not be too fast, so as to prevent people from being injured by the refrigerant; the speed of the refrigerant should not be too fast, so as to prevent the refrigerant oil in the compressor from being discharged with the refrigerant, once the compressor is intact after subsequent inspection , The lack of refrigeration oil will affect normal use. Pay attention to the color of the sprayed refrigerant. If the spray is white or colorless, the internal cleanliness of the system is high. The compressor may not be damaged, so be careful! 2. Remove the suction and exhaust pipe: nitrogen filling operation to avoid the generation of oxide scale inside the system, pay attention to whether there are impurities or foreign bodies on the inner wall of the copper pipe. 3. No-load operation: Before the old compressor is removed, ensure that the suction and exhaust pipe openings are open, and the running time is not more than 5 seconds. [This article from the refrigeration encyclopedia public number] judge whether the compressor unit is blocked or not Inhale and exhaust. To test whether the compressor has suction and exhaust, you can feel the finger close to the exhaust port; old compressors with poor insulation and high voltage and high operating current may leak electricity and cannot be tested in this way. 4. Remove and dispose of the old compressor: the old compressor must seal the suction and exhaust ports within 15 minutes; it must ensure that the old compressor code and machine barcode are clear; 5. Cleaning system: The cleaning fluid requires high-dissolved oil and is easily volatile. R11 is recommended; the nozzle of the welding place must be clean. 6. Replace with a new compressor: in principle, it is required to use the original model and original brand compressor. If it cannot be satisfied, the capacity of the new compressor must be consistent with that of the old compressor; scroll compressor and rotor compressor cannot be interchanged; single The phase compressor and the three-phase compressor cannot be interchanged; the rubber plug of the compressor must be removed before the exhaust pipe and the suction pipe; the maintenance process must ensure that the lubricating oil cannot contact the rubber feet of the compressor to avoid the deterioration of the rubber feet. 7. Welding new compressor: must be filled with nitrogen and welded, and ensure that the nitrogen reaches the welding position; it is appropriate to preheat until the copper pipe turns pink; the electrode must be melted by the temperature of the copper pipe, not directly by the flame.