The influence of capillary tube length on refrigeration system parameters and troubleshooting

The capillary tube generally refers to a slender copper tube with an inner diameter of 0.4~2.0mm. As the throttling mechanism of the refrigeration system, the capillary tube is the simplest one. Because of its low price and flexible selection, it is widely used in small refrigeration devices. So what effect does the capillary length have on the refrigeration system parameters? How to eliminate the "ice blocking" phenomenon in the capillary? Let's take a look!

The influence of capillary tube length on refrigeration system parameters

Influence on suction and discharge temperature and pressure

At the same charge volume, the shorter the capillary tube, the greater the refrigerant flow rate, so the suction temperature and the discharge temperature will decrease; similarly, when the capillary tube is fixed, the greater the charge volume, the greater the refrigerant flow rate and the suction temperature, The exhaust temperature also drops.

However, the increase in flow rate increases the suction pressure. For the exhaust pressure, when the filling volume is constant, the shorter the capillary tube is, the smaller; and when the capillary length is fixed, the larger the filling volume is, the higher the filling volume.

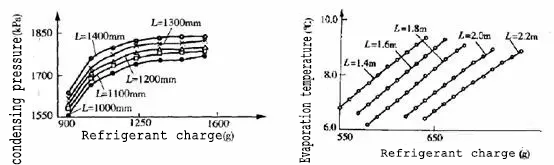

2 Influence on condensation temperature and pressure

When the refrigerant charge is constant, the shorter the capillary tube, the lower the condensation temperature and pressure;

When the length of the capillary tube is fixed, the greater the charge, the higher the condensation temperature and pressure;

3 Influence on evaporation temperature and pressure

When the refrigerant charge is constant, the shorter the capillary tube, the higher the evaporation temperature and pressure;

When the length of the capillary is fixed, the greater the filling volume, the greater the evaporation temperature and pressure.

4 Influence on supercooling and superheating

When the refrigerant charge is constant, the longer the capillary tube, the greater the degree of subcooling and the higher the degree of superheating;

When the length of the capillary tube is constant, the greater the filling volume, the greater the degree of supercooling and the lower the degree of superheating.

5Influence on cooling capacity, power consumption, EER

When the refrigerant charge is constant, the longer the length of the capillary tube, the lower the power consumption, but the cooling capacity also becomes smaller, and the EER becomes smaller;

When the charge volume increases to a certain extent, because of the greater influence of the heat exchange temperature difference, the cooling capacity becomes larger and the EER becomes larger.

6 Design points of capillary system

1) On the high-pressure side, the accumulator is generally not used. In fact, whether the accumulator is used does not depend on what kind of throttling device is, but depends on whether the operation of the entire system is required, such as a heat pump system, a shutdown evacuation system. For refrigerators, air conditioners, etc., the original system design rarely needs a liquid reservoir.

2) In the suction pipe, it is best to use a gas-liquid separator. For refrigerators, if the return pipe is relatively long, it can ensure that the return air temperature is within the design requirements (the compressor company recommends a minimum of 5oC). Most air-conditioning compressors come with a gas-liquid separator when they leave the factory.

Because the capillary system is shut down, the high and low pressure sides will balance and the evaporator will accumulate refrigerant liquid, the gas-liquid separator can well prevent liquid hammer and refrigerant migration.

3) The high-pressure side can contain all the refrigerant charged, which prevents damage to the high-pressure piping system and compressor when the capillary is blocked.

4) Under high load conditions of the evaporator, because the capillary system can be fed back to the condenser side, the condenser should consider whether the condensing pressure will be too high under this condition, so it is necessary to increase the condensation heat exchange area.

5) It is best not to accumulate refrigerant liquid in the pipeline between the condenser outlet and the capillary inlet;

One theory is that when the compressor is stopped, this part of the refrigerant liquid will evaporate due to the pressure drop, and then condense after flowing into the evaporator, thereby bringing some heat to the refrigeration space, which may have an impact on the enclosed space of the refrigerator. For air conditioners, this part of heat can be ignored;

Another way of saying this is that this will delay the balance of the high and low pressure sides, which may cause problems when the low torque compressor restarts. This can generally be solved by adding a delay to the control (in fact, this is for reducing the starting current and other electrical appliances. The impact of components or power grids is also beneficial).

6) A filter must be added to the capillary inlet to prevent clogging, especially the HFC refrigerants currently used, such as R134A, R404a, R410a, etc. are more sensitive to moisture, and a dryer is required in the design.

7) Before the refrigerant enters the capillary tube, it is best to have a certain degree of subcooling. This can be achieved by adding a section of supercooling tube to the evaporator, or heat exchange with the suction tube, so as to minimize the flash of gas in the capillary tube. Increase cooling capacity and ensure refrigerant flow.

However, it should be noted that under low temperature conditions, the subcooling may be too large due to a little liquid back in the suction pipe, thereby increasing the capillary flow rate, which in turn increases the degree of subcooling, which may eventually cause liquid back.

How to eliminate the capillary ice blocking phenomenon

"Ice blockage" is caused by poor vacuum processing of the refrigeration system, excessive water content in the system, or excessive water content of the refrigerant itself. "Ice blockage" mostly occurs at the outlet end of the capillary tube. When the liquid refrigerant evaporates from the capillary tube to the evaporator, its volume greatly expands and becomes gaseous, absorbing a large amount of heat. At this time, the evaporation temperature can reach about -5 degrees, and the trace moisture in the system freezes into ice when the refrigerant circulates to the outlet end of the capillary tube. As the refrigerant continues to circulate, the volume of ice formed gradually increases, and to a certain extent, the capillary tube is completely blocked.

How to judge the capillary "ice block"

Judgment method 1: After the power is turned on and the compressor starts to run, the evaporator is frosted and the condenser heats up. With the formation of "ice block", the evaporator frost is all gone, the compressor is running with dull sound, and there is no cold air blowing into the room . After stopping, wrap the capillary tube with a hot towel several times to enter the entrance of the evaporator. After the ice block melts, you can hear the sound of refrigerant flowing in the pipeline. After starting the compressor, the evaporator begins to frost again. After running for a period of time, the above situation will occur again, which can judge the capillary ice block.

Judgment method 2: (1) A three-way overhaul valve is installed on the liquid filling process pipe of the compressor. ⑵Start the compressor, after running for a period of time, if the low pressure has been maintained at the position of 0Pa, it indicates that the capillary tube may be in a semi-dirty blocked state. If it is vacuum, it may be completely dirty and should be further checked. There is a dull sound when the compressor is running. ⑶ After stopping the compressor, if the pressure balance is very slow, it takes ten minutes or more than half an hour, indicating that the capillary tube is dirty. The location of dirty blockage is generally at the joint between the filter drier and the capillary tube. If the connection between the capillary tube and the filter drier is cut off, the refrigerant is sprayed out, which can judge that the capillary tube is dirty.

How to eliminate capillary "ice block"

After confirming that the capillary tube is "ice blocked", first release the refrigerant in the refrigeration system and perform the vacuum drying process again. The main components of the refrigeration system evaporator and condenser are cleaned once. When reconnecting the refrigeration system, it is best to replace with a new filter drier. If there is no new filter drier, you can remove the removed filter drier, pour out the molecular sieve inside, wash the inner wall of the filter with gasoline or carbon tetrachloride, and use it after drying.

If it is caused by the excessive water content of the refrigerant itself and the formation of "ice blockage", a filter drier can be added at the outlet of the refrigerant cylinder. So that when the refrigerant is charged, moisture is absorbed