The adjustment principle of the screw compressor slide valve is actually very simple!

Screw compressor is composed of a pair of parallel, intermeshing female and male screws, which is widely used in medium and large refrigeration systems. Screw compression is divided into single screw and twin screw. Generally speaking, screw compressor refers to twin screw compressor. Screw compressor has the following characteristics:

1. The screw refrigeration compressor has a simple structure, a small number of parts, no vulnerable parts such as air valves, piston rings, rotors, bearings, etc., and its strength and wear resistance are relatively high.

2. The screw compressor has the characteristics of forced air delivery, that is, the displacement is almost unaffected by the discharge pressure, and there is no surging phenomenon when the displacement is small, and it can still maintain a relatively high temperature in a wide range of working conditions. High efficiency.

3. Screw compressors are not very sensitive to liquid hammer and can be cooled by oil injection. Therefore, under the same pressure ratio, the exhaust temperature is much lower than that of the piston type, so the single-stage pressure ratio is higher.

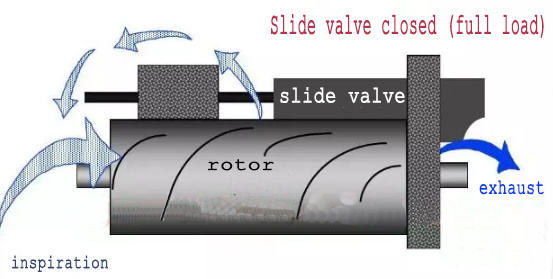

4. The slide valve is used to adjust, which can realize stepless adjustment of energy. The focus of this article today is to analyze the principle and process of the adjustment of the screw compressor slide valve.

We must know that the spool valve is used to control the capacity steplessly. After the normal shutdown, the component is not loaded. The spool valve is controlled by the micro-control board through oil pressure, which ultimately changes the compressor's refrigeration capacity.

(The slider above)

The following 3 pictures illustrate the process of the spool valve from being loaded to full load. Pay attention to the position changes of the piston and spool valve in the picture.

Through the left and right movement of the slide valve, the effective compression volume is increased or decreased, and the air volume is adjusted. When loading: the piston moves to the left to drive the slide valve to move to the left, and the air delivery volume increases; when the load is reduced: the piston moves to the right to drive the slide valve to move to the right, and the air delivery volume decreases.