Figure 1: A variety of air cylinders.

Styles of Air Cylinder

Cylinder is used in many positioning, driving and clamping applications.

Choices for air cylinder style include:

Tie Rods-Tie rod cylinders are held together by external tie rods, usually with a rectangular bolt pattern. They are available for all types of cylinders and loads of various sizes. Tie rods can be used to protect the cylinder from damage, but the tie rods must be tested at high torques to ensure that the tie rods do not stretch under high pressure.

Smooth body- In a smooth cylinder, the body of the cylinder is smooth and usually encloses the piston.

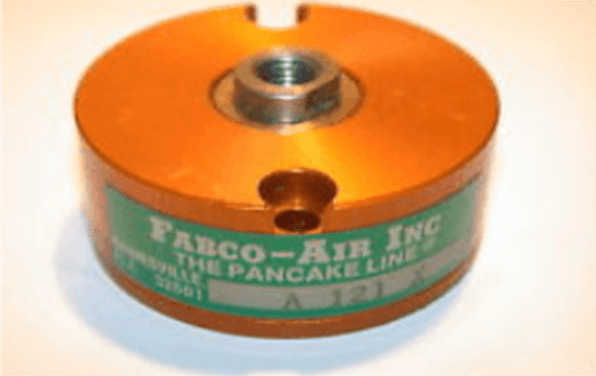

Pancake- Pancake cylinder has a shorter length and larger diameter than other air cylinder styles, which makes the cylinder looks like a “pancake". The piston rod may not be entirely encased in the frame.

Figure 2: The appearance and design mode of pancake cylinder.

Miniature- The miniature cylinder works in the same way as a regular sized cylinder, except that its profile is smaller and the body may be threaded for installation purposes. They may be as small as 2.5 mm and are mainly single acting cylinders for lightweight micro components and manufacturing.

Figure 3: The appearance and design mode of miniature cylinder.

Ram- A ram is a device in which the cross-sectional area of the piston rod is lager than half of the cross-sectional area of moving parts. The ram is primarily used to push rather than pull and is most commonly used in high pressure applications.

Welded- A smooth hydraulic cylinder with heavy welded cylinder housing to provide stability.

Rectangular- The rectangular cylinder is encased in a rectangular box frame.

Rotating- Rotary actuator uses air pressure to generate rotary motion. This type of actuator usually provides angular rotation up to 360 °. The rotary actuator can be a blade design or a rack and pinion design.

Heat in part areas will also cause additional internal stress in the cylinder itself, which will lead to cracks in the cylinder head. If the operating temperature exceeds the normal temperature, it will cause serious effects.

Figure 4: The appearance and design mode of rotating cylinder.

Multiple bore- In multiple bore cylinder, two or more bores and pistons are combined or stacked in the same cylinder.

Rodless- Rodless actuator uses a mechanical or magnetic coupling to apply force to the carriage that moves along the length of the cylinder block.

Characteristics of Air Cylinder

Many air cylinders have better availability and performance.

Adjustable stroke- Adjustable stroke allows to change the end point or entire stroke length.

Air/Oil tandem- Air/oil Tandem provides smooth, hydraulic-like motion. This combination is only for cylinders.

Bumper- Bumper, also known as cushion, slows down the piston before it stops. The unbuffered cylinder stops the piston by striking the end cap. Energy and noise from the piston and piston rod must be dissipated throughout the cylinder. This is usually very loud and will eventually lead to fatigue of the piston and end cap materials. In case of large piston or static state, the buffer can be adjusted for smaller and lighter work.

Figure 5: The appearance and design code of crankshaft shock absorber.

Figure 6: The appearance and design code of bumper.

Double-end rod- The double end rod extends from both ends of the cylinder, and both ends are provided with connection features such as threads.

Multi-position end-plate- The multi-position end-plate can be driven to different positions along its stroke, not just the end points.

Integrated overload slip clutch or torque limiter- the integrated flow control incorporates a flow control valve that limits the amount of air or fluid entering the cylinder.

Protective sleeve- Protective sleeve is a cover that protects moving parts from environmental damage.

Self-locking- When the signal is lost, the self-locking actuator is locked in the current position.

Integrated sensor- Integrated sensor is provided in the cylinder to monitor position and proximity.

Integral flow- integral flow control contains a flow control valve or device that limits the amount of fluid air entering the cylinder.

Non-rotating- Non-rotating means multiple rods to prevent the plunger from rotating.

Magnetic switch- Magnetic switch such as Hall effect sensor signals indicate whether the propeller is in the retracted or extended position.

Figure 7: the appearance and design mode of magnetic switch of air cylinder.

Thermal overload protection- thermal overload protection is used to trip the switch when the preset temperature is exceeded.

Intrinsic safety- Intrinsically safe electric linear actuators can be used in hazardous environments such as chemical processing facilities.

Water-proof- The device is sealed to prevent corrosion caused by water or liquid entering the housing.

Related Info

Test and Diagnosis of Cylinder SealingTypes of Cylinder Seals and Factors Affecting Sealing Performance

The Structure and Basic Working Principle of Air Cylinder

The Types of Air Cylinder and Notices for Use

The Importance of Air Cylinder Piston Sealing Ring and Solutions to Air Leakage