Process installation and energy saving measures in the operation of refrigeration system

Refrigeration is the operation of lowering the temperature of the material to be cooled to below the temperature of water or ambient air. The purpose of the refrigeration process in the composition ammonia device is: in the process of ammonia composition, liquid ammonia is used to evaporate and absorb heat in the ammonia vaporizer, and the ammonia will pass through The recirculating gas after the compression cooling is further cooled to below normal temperature to condense gas ammonia into liquid ammonia. After transpiration, gas ammonia is compressed, cooled and condensed, and then converted into liquid ammonia, which is recycled and used in small cold storage equipment.

1.Basic principles

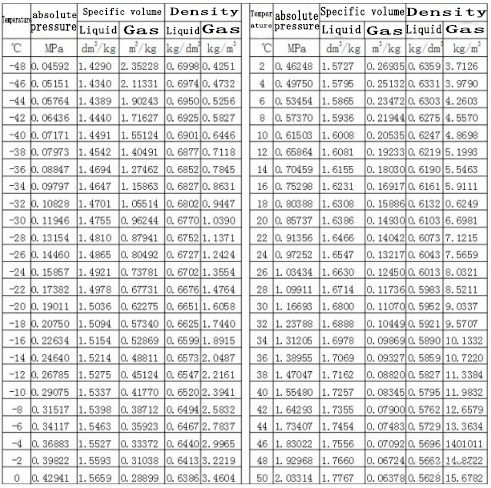

The transpiration of liquid ammonia and the liquefaction of gaseous ammonia, according to the principle of gas-liquid balance, we know that the transpiration temperature of liquid ammonia is related to the full steam pressure. The lower the transpiration temperature of liquid ammonia, the smaller its full vapor pressure and the greater the heat of vaporization; on the contrary, the opposite is true. Therefore, in actual production, the evaporation pressure of liquid ammonia can be determined according to the requested freezing temperature to reach the requested cooling temperature. After the liquid ammonia is transpired into gas ammonia, it is necessary to liquefy it from the beginning and recycle it. It can be seen from Table 1: the condensation temperature of gas ammonia is added with the increase of pressure. When the pressure has increased to a certain level, the condensation temperature will be higher than the cooling temperature. At this time, it can be liquefied with a simple water cooler.

R717 (ammonia) refrigerant temperature and pressure comparison table

2. Ammonia compressor device

(1) The detailed device request (including test run and inspection request) of various ammonia compressors shall conform to the current "General Specification for Construction and Inspection of Mechanical Equipment Installation Engineering" (GB50231-98), and shall conform to the skill requirements of the corresponding product samples. Before ramming the foundation of the ammonia compactor, it is necessary to check the construction drawing of the foundation with the objects to verify the orientation of the screw holes and the length of the bolts. It can be connected and firm when grouting.

(2) Auxiliary equipment and pressure vessels in the ammonia refrigeration system (such as oil-ammonia separator, transpiration condenser, high-pressure liquid reservoir, auxiliary liquid reservoir, central cooler, low-pressure circulation barrel, ammonia liquid separator, drain Barrels, air separators, oil collectors, emergency ammonia drains, etc.) It is necessary to check the factory qualified certificates before the installation. If there is no qualified certificate or if damage is found after transportation, the robustness and air tightness test should be carried out. The pressure test conditions are as follows Standardize the "Steel Pressure Vessel" (GB150-89) technical conditions rules. It is necessary to check the positioning of the bolt holes for the refrigeration auxiliary equipment before ramming. In addition to the requirements indicated in the drawings, the installations of auxiliary refrigeration equipment must generally be straight, strong and accurate, with accurate connection pipelines, oil-ammonia separators, condensers and other sensational pressure vessels. The anchor bolts should be double-screws. Cap or add spring washers. When installing low-temperature pressure vessels, skids should be added to minimize cold bridges. The skids should be oil-soaked skids.

(3) All measuring surfaces and components must be made of special ammonia products, and their accuracy and sensitivity should be approved according to relevant product samples or technical documents before installation. Condensers, oil-ammonia separators, high-pressure reservoirs, high- and low-pressure conditioning stations, auxiliary ammonia storage, oil collectors, central coolers, low-pressure circulation barrels, high- and low-pressure containers such as ammonia refueling stations are equipped with pressure gauges, The pressure gauge for ammonia should not be less than 2.5 accuracy. All appearances should be well-lit, easy to investigate, and not obstruct the orientation of operation and maintenance.

(4) The refrigeration system piping should use special valves and fittings for ammonia, whose nominal pressure is ≥2.5MPa, and must not have copper, galvanized, or tinned parts. Various valves used in the ammonia system (such as stop valves, throttle valves, check valves, safety valves, float valves, solenoid valves, electric valves, and float type liquid level indicating devices, etc.) must be individually tested for their sensitivity and Tightness. It is necessary to pay attention to the flow direction of various valve devices, and do not install them backwards, and it is necessary to straighten the valve device, and the valve handle is strictly forbidden to face down. Before installing the safety valve, check the status of the lead seal and the factory certificate, and do not open it at will. If the pressure does not match the planned pressure, the safety valve should be adjusted according to the professional skills rules, and the pressure adjustment record should be made. After the professional and technical personnel pass the inspection, they shall be sealed again. The opening pressure of the safety valve installed on the high-pressure vessel is 1.85Mpa, and the opening pressure of the safety valve installed on the low and medium pressure vessels and pipelines is 1.25MPa.

3. Energy saving in the operation of refrigeration system

(1) Avoid too low transpiration temperature. Too low transpiration temperature will reduce the refrigeration coefficient and increase energy consumption. If the transpiration temperature is too low, the heat transfer area of the evaporator may be too small and the compressor is too large. At this time, it should be calculated from the beginning, and it is better to use other methods to solve the problem.

(2) Avoid excessively high condensing pressure. The increase in condensing pressure causes a decrease in the refrigeration coefficient and an increase in energy consumption. Excessive condensing pressure is not only because the condensing area selected in the plan is too small and must be increased, but also factors such as scaling during system operation, lack of cooling water, and non-condensable gas in the condenser should be considered. Attention should be paid to timely sweeping of non-condensable gases, regular elimination of fouling, and checking the amount of cooling water to avoid excessively high salinity due to transpiration and affecting condensation.

(3) Avoid excessive exhaust temperature. Excessive exhaust temperature will make it smooth and bad, increase friction work, and reduce the power of the compressor. The factors that cause excessive exhaust temperature should be removed in time. For example, avoid excessively high condensing pressure, avoid excessively high suction temperature, too small amount of cooling medium or too high temperature of the compressor.

(4) Strictly control the oil pressure and oil level of the compressor. If the oil pressure and oil level are too high, the oil consumption will increase and the power consumption will increase. So pay attention to the role of the oil separator to avoid excessive oil storage in the system. But in any case, there is always oil to enter the condenser and evaporator, which will cause an oil film in the condenser or evaporator to increase the thermal resistance, decrease the heat transfer power, increase the condensation temperature, and decrease the evaporation temperature. Therefore, the oil accumulated in the system should be discharged regularly to improve the heat transfer function of the system and reduce power consumption.

(5) Regular maintenance of the compressor. After the compressor has been running for a period of time, it may show signs of wear or damage of parts, poor sealing function, etc., which all lead to increased power consumption. Therefore, the compressor should be maintained regularly to keep all components of the compressor in normal condition. Operating status to reduce power loss.

(6) Reduce the cooling load as much as possible. Strengthen the maintenance and management of the refrigeration system, strictly control the number and time of emptying or draining oil and water, and often check the sealing function of the system. Take care of the anti-corrosion and heat preservation of the refrigeration system together to prevent cold loss. And try to maintain the stability of the load of the tower system.