Installation and debugging methods and essentials of buffer hot water storage tank in heating system

With the large-scale promotion of "Coal to Electricity" and "Coal to Clean Energy" projects, the use of air source heat pumps for independent domestic heating has become one of the leading energy-saving, comfortable, clean and stable ways. This article analyzes the installation method and essentials of the buffer hot water storage tank equipped with the buffer hot water storage tank in the air source heat pump system.

Preface: As an important part of the air source heat pump heating system, the buffered hot water storage tank is no longer an optional accessory. The "2017 Guiding Opinions on the Promotion of Clean Heating in Rural Areas in Winter" clearly stated: "The air source heat pump system must be equipped with a water storage tank (ie buffer hot water storage tank) of no less than 60 liters." In response to this guidance, the China Energy Conservation Association Heat Pump Special Committee and the China Heat Pump Industry Alliance Enamel Hot Water Storage Tank Special Committee organized the drafting of "T/CECA-G0014-2017" Air source heat pump heating system buffer hot water storage tank installation specifications "Group Standards". The promulgation of this standard provides a basis for the use and acceptance of the installation of the buffered hot water storage tank in the air source heat pump heating system.

1.The structure type and installation example of the buffer hot water storage tank

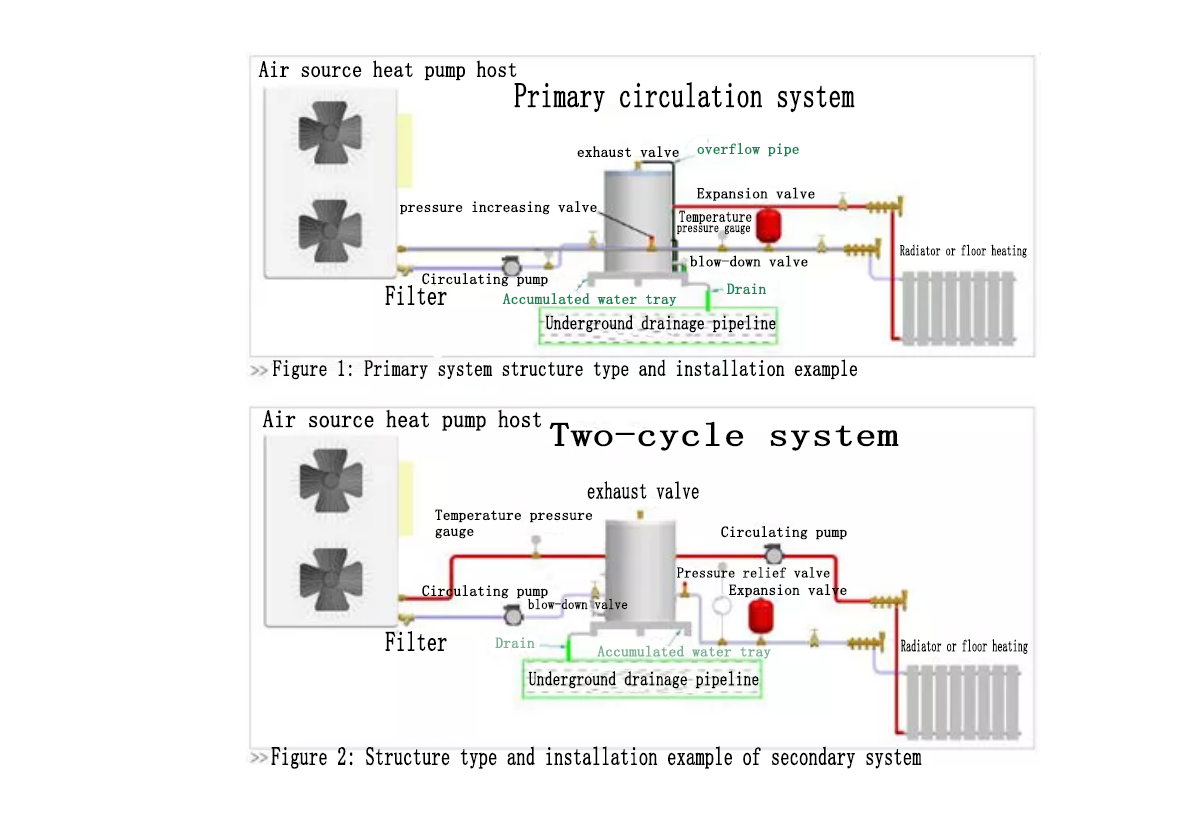

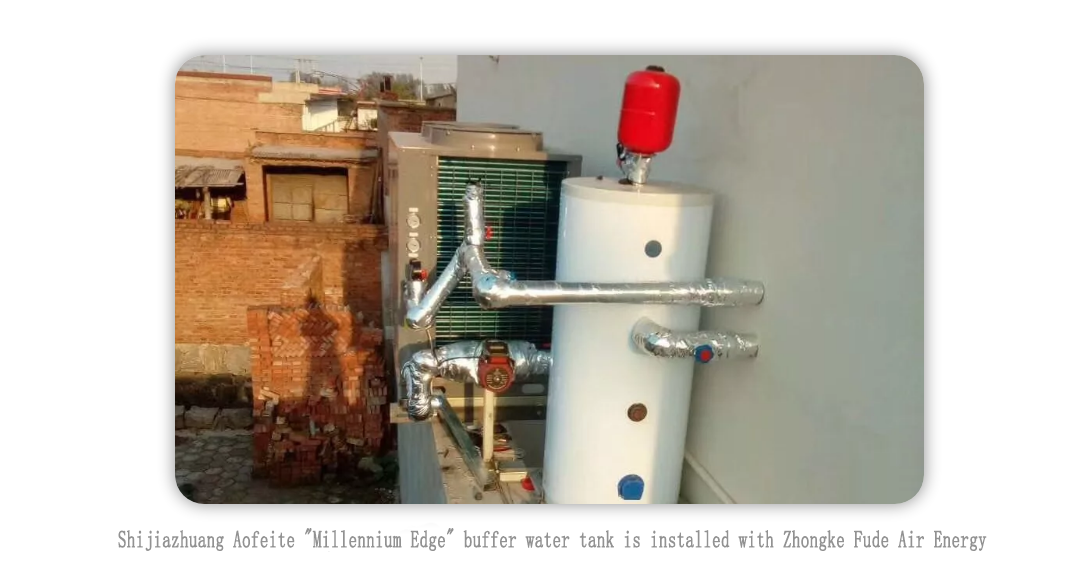

Of the two systems, Figure 1 shows the primary circulation system, and Figure 2 shows the secondary circulation system. These two operating systems are the most commonly used types of schemes in coal-to-electricity projects in the north. The buffering hot water storage tank used in the two installation examples adopts a vertical structure, and the water tank liner is an enamel liner, which has strong corrosion resistance and pressure bearing capacity.

The buffer hot water storage tank used in the primary circulation system in Fig. 1 has two circulation inlet and outlet ports, and the buffer hot water storage tank used in the two circulation system in Fig. 2 has four circulation inlets and outlets. The circulation inlet and outlet specifications are all DN32 internal threads. , Both types of circulating water tanks are equipped with exhaust valves and magnesium rods as standard, and are reserved for sewage port, temperature probe port and water replenishment port (generally, the specifications of these pipe ports are DN20).

Some buffer hot water storage tanks also have a pressure relief valve interface and a temperature pressure gauge installed. Installing these configurations and pipe interface fittings on the buffer hot water storage tank can greatly improve the installation efficiency and reduce the trouble of fixing the fittings on the pipeline.

For the selection of the buffer hot water storage tank, it is recommended to use an enamel water tank. The buffered hot water storage tank made of enamel liner is used in the air source heat pump heating system. It has many advantages such as strong corrosion resistance, strong pressure bearing capacity, excellent insulation performance, buffer system pressure, stable system operation, and automatic exhaust.

Especially in the north, due to the difference in water quality, the heavy metal mineral content in the water source in the north is relatively high, that is to say, the water quality is relatively hard and it is easy to accumulate fouling. Generally, the welding seam of the buffer hot water storage tank with stainless steel inner tank The area is easily oxidized and corroded, which directly causes the service life of the water tank to be far shorter than the operating life of the host system, which increases the probability of replacing the water tank and the frequency of after-sales service. The enamel buffer hot water storage tank completely overcomes these defects, which is also the key factor for many companies in the industry to choose the enamel buffer hot water storage tank.

2. Installation and debugging methods and installation essentials of the buffer hot water storage tank

1. Installation and debugging method

a. Installation of various pipe connections and pipe joints of the buffer hot water storage tank:

The connection and installation of the pipe joint and the water tank are generally sealed with raw material tape. The sealing and installation with raw material tape is simple and quick, but there are disadvantages when installing with raw material tape. First of all, the service life of the raw material tape is not too long (generally 1~ It will decay in 2 years); secondly, if the raw material belt is exposed to the sun or rainy areas for a long time, it will be easily damaged, and its sealing will be affected; thirdly, the installation level and installation habits of the installers are not All the same, its installation and sealing quality is greatly affected by human factors.

Here, the author suggests that metal pipe thread sealant should be used for sealing installation of threaded connections of our products, which is more reliable. Metal pipe thread sealant has all-weather use, good sealing performance, high quality and heavy load, corrosion resistance, lubrication of pipes, can conduct static electricity, convenient disassembly and long service life (the service life of metal pipe liquid sealants can generally be the same as the product life )Etc.

The installation arrangement of the pipes and pipes connecting the buffer hot water storage tank and the system: For the connecting pipes and pipes, most of them are made of plastic pipes and fittings. The selection criteria should comply with GB/T18991 "Thermoplastic pipes and pipes for hot and cold water Level 4 in "Pipe Fitting". Regarding the pipe fitting, site fitting and related matters needing attention, there are many items in clause 8 of GB50242-2002 "Code for Construction Quality Acceptance of Building Water Supply and Drainage and Heating Engineering" and clause 5.4 of JGJ142-2012 "Technical Regulations for Radiant Heating and Cooling" Clear regulations and reference basis.

Valves directly connected to the buffer hot water storage tank: especially in the two systems (Figure 2), since the host and the terminal are operated and controlled independently, some control valves will be installed near the loop interface of the buffer hot water tank , Such as manual gate valve, check valve or electric valve and so on.

These valves generally have a cut-off control function on the main pipe of the system. For the installation of these valves, please refer to the provisions of 9.2.4 in GB50243-2016 "Code for Construction Quality Acceptance of Ventilation and Air Conditioning Engineering" for installation and inspection.

b. The installation of the buffer hot water storage tank and the water accumulation chassis:

Regarding sewerage installations, only some areas have strict regulations regarding the conversion of coal to electricity in the northern region. I think that the installation of sewerage chassis should be given high priority, because the vast majority of coal-to-electricity installations in northern regions are in rural areas. The installation location, environment and structure of the house are different in each region, so we still recommend the use of a water trap device.

There are great advantages to adopting the drip tray device: firstly, the drip tray can be used as a diversion channel, and any water pipe, overflow pipe and sewage pipe can be integrated in the drip tray to discharge to the sewer; secondly, in the installation and commissioning and subsequent The water leakage at the installation interface that may occur during system maintenance can be directly discharged to the sewer through the drip pan (refer to Figure 1 and Figure 2).

Therefore, the water trap avoids the messy phenomenon of draining water from multiple overflow pipes such as the exhaust valve overflow port, the pressure relief valve overflow port and the sewage port. Therefore, the installation of the water tank on the drip tray has absolute advantages.

The drip pan is part of the installation frame in the entire system, and it is clearly stipulated in the group standard 4.3.1 of T/CECA-G0014-2017 "Code for Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating Systems" issued on June 20, 2017 : "The mounting frame and fasteners used in the installation of the water tank should be able to meet the installation strength requirements of the water tank, and the load-bearing capacity of the mounting frame and fasteners should not be less than 4 times the full weight of the water tank."

In addition to the installation strength of the water tank and the water pan should meet the requirements, we suggest that the water tank should be fixed on the surface of the water pan, and its fixing strength should also meet the requirements. After the water tank and the water tray are fixed, the water tray and the ground should be fixed by expansion bolts, so as to ensure the fixing strength and stability of the entire system.

c. Installation of wall-mounted buffer hot water storage tank:

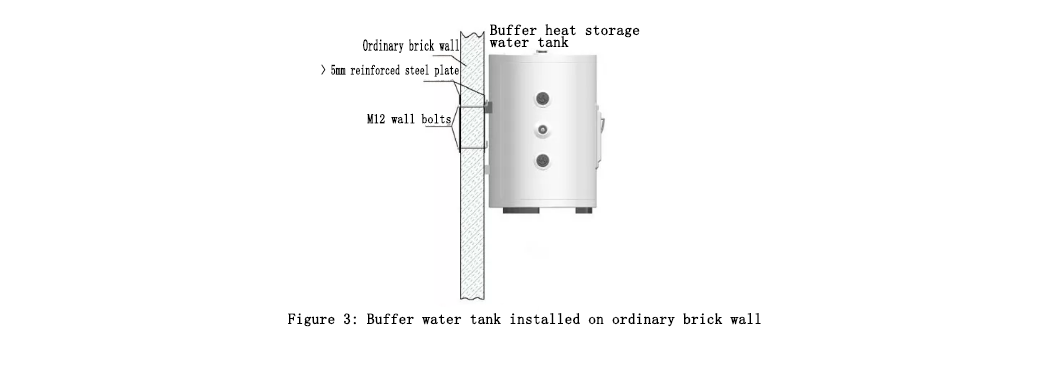

Limited by the installation area or conditions, the installation of buffer hot water storage tanks in some apartment types must be wall-mounted. The installation of wall-mounted buffer hot water storage tanks in rural areas in the north is particularly important for the fixing of the water tank on the wall. In the case of reinforced concrete pouring, it can be installed directly with only two expansion bolts, but the walls of many houses cannot meet the load-bearing requirements after the water tank is filled with water. In this case, the author recommends two different walls Installation method:

The first method is shown in Figure 3: The wall-mounted buffer hot water storage tank in the figure is installed on an ordinary brick wall. The installation on an ordinary brick wall must consider the load-bearing capacity of the entire wall. The method shown in the figure is to first use two steel plates with a thickness of more than 5mm to be embedded in the front and back walls. On the two steel plates, open the wall screw holes according to the center distance of the hook of the water tank installation hanger, and then use the wall screws to fix the two steel plates. A steel plate is fixed on the wall, and finally the water tank is hung on the surface of the steel plate.

This method is widely used in many engineering cases.

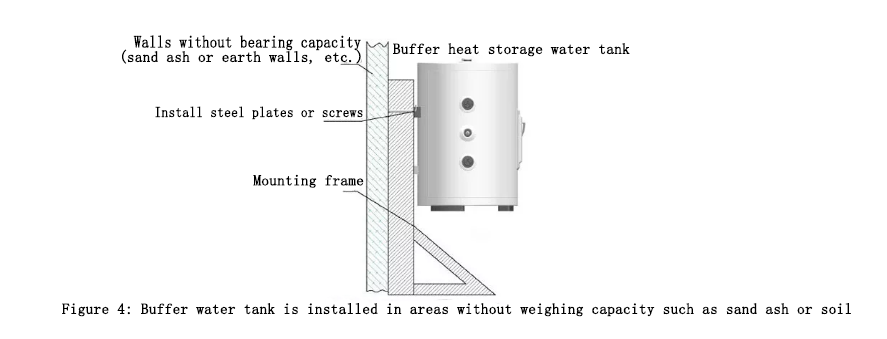

The second method is shown in Figure 4: This installation method is for installation areas with no load-bearing capacity such as sand dust or soil walls. In this case, only the installation frame can be customized or the installation surface that meets the load-bearing requirements can be re-made for installation. Therefore, for wall-mounted buffer hot water storage tanks, the prerequisite is the bearing capacity of the mounting surface or mounting frame. At the same time, the operational stability of the water tank after installation and the convenience of subsequent maintenance should be considered during the installation process.

d. Test and debugging:

The test and debugging of the buffer hot water storage tank after installation are mainly carried out in conjunction with the entire system, and no single component or individual in the system can be operated or tested independently. Clause 5.2.1 of the group standard T/CECA-G0014-2017 "Specification for Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating System" issued on June 20, 2017 clearly stipulates that the complete set of combined installation of water tank and air source heat pump heating system is completed. After that, the trial operation can be carried out.

For the test and commissioning after the system is installed, you can refer to clause 8.6 in the standard GB50242 "Code for Acceptance of Construction Quality of Building Water Supply and Drainage and Heating Engineering" or clause 5.6 in JGJ142-2012 "Technical Regulations for Radiant Heating and Cooling".

2. Installation essentials

a. Pay attention to the choice of installation location:

"Air source heat pump heating system buffer hot water storage tank installation specification" clause 4.2 of the group standard has detailed requirements and regulations on the selection of installation location, mainly divided into two parts, one is to combine the system requirements and the user's environmental conditions; the other is to Meet the requirements of environmental protection and city appearance.

b. All pipe connections of the buffer hot water storage tank are standard cylindrical pipe threads, and the pipe joints installed with it should be matched strictly according to the specifications.

The quality of cylindrical pipe thread fittings currently purchased on the market is rather messy. When selecting, you must choose the cylindrical pipe thread fittings required by the national standard. Only in this way can it match the threads of the water tank products on the market.

In order to save installation costs, some installation units blindly pursue low-priced accessories. The quality of these accessories generally does not meet the requirements of the national standard. When installing, the installer can only use multiple wraps of raw material to seal, maybe the initial trial operation I can't see anything, but after a long time, the seal of the pipe interface will easily leak, which brings endless hidden dangers of after-sales maintenance. This is a practice that does not pay for the gain, so when choosing such installation accessories as cylindrical pipe threads, be sure to choose accessories that meet the requirements.

c. Thermal insulation and drainage measures of drainage overflow pipe:

Among the components associated with the installation of the buffer hot water storage tank, there are three major components with drainage or overflow, mainly the exhaust valve overflow port, the pressure relief valve overflow port and the sewage valve drainage device. These three components will cause water or water vapor to overflow to different degrees during use. The water vapor discharged from the exhaust valve will form a condensed water discharge. The pressure relief valve will automatically open to relieve the pressure when the water temperature in the water tank is at high temperature and high pressure. The expansion water flow in the water tank will overflow the pressure relief valve overflow port. The use of the sewage valve is used in the system After a period of time, when the water source in the system needs to be replaced, the replaced water source will be discharged from the drain valve.

If the water or vapor discharged from these three components is not handled properly, it will have a certain impact on the normal life and work of others. In the low temperature in winter, the overflowing water or vapor will instantly freeze and freeze, once the overflow is blocked. , The exhaust valve and the pressure relief valve will lose their function, which will have a great impact on the normal operation of the system, and even cause the system to be paralyzed. Therefore, the insulation and drainage measures of these overflow ports are particularly important. "Air source heat pump heating system buffer hot water storage tank installation specifications" clauses 4.2 and 4.5 of the group standard have requirements and regulations on drainage measures and performance requirements of drainage pipes.

4.5.7 Regulations: The pipes and valves installed in connection with the water tank shall be insulated and the insulation material of the outdoor part shall be covered with a protective layer. This regulation clearly requires all drainage and overflow pipes to be unblocked at all times.

As for the drainage measures of drainage and overflow pipelines, the standard also clearly stipulates that sewage should not be directly discharged on the walls of buildings and outdoor roads. The author suggests that whether it is an overflow pipe or a sewage pipe, you can refer to the schemes in Figure 1 and Figure 2 in this article, and concentrate all the drainage pipes on the water tray for discharge, and install the discharge pipe at the bottom of the water tray directly to In the sewer or other pipelines that are conducive to discharge, in this way, the installation of the entire system not only meets the standard requirements, but also is safe and beautiful.

Third, the installation essentials of the main components associated with the buffer hot water tank

1. Installation of exhaust valve and pressure relief valve:

Although the functions of the exhaust valve and the pressure relief valve are different during use, the installation process is still the same.

"Air source heat pump heating system buffer hot water storage tank installation specifications" group standard 4.5.2 stipulates: the supporting safety valve should be installed according to the requirements of the product description, and the installation position and direction of the safety valve should not be changed at will. The discharge pipe of the safety valve should be installed in a continuous downward manner to avoid water accumulation in the pipe, and ensure communication with the atmosphere, unblocked drainage and safety. In cold climate areas, the discharge pipe should be prevented from being blocked due to freezing.

Standard 5.2.3 also stipulates for the trial operation of the safety valve: Manually operate the safety valve to confirm that the water tank can normally release pressure. The installation essentials of these two valves are very detailed in the standard. In the connection and fixation with the water tank pipe interface, it is recommended to use liquid thread glue for sealing.

2. Installation of the blowdown valve:

The blowdown valve is an important drainage device in the system. Its installation has a certain impact on people’s daily life, the discharge of system sewage, and whether the pipeline layout is reasonable. Therefore, the blowdown valve and the associated pipeline layout and The installation must strictly follow the requirements of the group standard 4.5.4 of the "Code for Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating Systems".

3. Installation of temperature probe cable:

The temperature probe is a necessary component in the system to measure the temperature of the circulating water. After the buffer hot water storage tank is installed in the system, most companies no longer install the temperature probe on the pipeline, but directly install it on the water tank. .

The water tank is generally equipped with a blind pipe device with an inner hole of about 8mm in the lower part of the middle. When installing, just insert the probe directly, but pay attention to the firm fixation of the temperature probe wire when installing. The blind pipe device on the lower tank will be matched with the PG7 waterproof connector. The waterproof connector of this specification plays a role of fixing the probe line and sealing, so the installation of this part during the installation process cannot be ignored.

There is a detailed provision for this device in clause 4.5.9 of the group standard "Code for the Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating Systems": The temperature probe wires or other signal wires connected to the water tank should be installed with waterproof connectors, Take effective measures to prevent loosening or easy pulling.

Four, with auxiliary electric heating structure type buffer hot water storage tank installation essentials

In order to prevent the extreme cold weather and the special situation of the system failure in the northern area, most of the buffer hot water storage tanks used in the coal-to-electricity conversion in the northern area are equipped with an auxiliary electric heating system, in order to ensure that the electric heater has sufficient heating capacity , That is, once the host system fails or shuts down due to extremely cold weather, the comfort of the terminal will not be affected. The power of electric heating is generally around 3000W. To install such a high-power hot water heating device in a home, electrical safety is particularly important.

According to the group standard related to the electrical part of the "Code for Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating Systems" just released, the author shares the following essentials with colleagues:

1. This standard quotes GB4706.32 "Special requirements for safety heat pumps, air conditioners and dehumidifiers for household and similar electrical appliances (IEC60335-2-40)", the part of the buffer hot water storage tank involved in the installation process of electrical All must comply with this standard.

2. According to 4.1.1 of the standard, the installation personnel of the water tank shall receive professional training and obtain corresponding qualifications before they can engage in installation work. The installation of the electric heater part of the buffer hot water storage tank is already a special installation work, and the installer must be qualified for electricity.

3. In 4.4.5 of the standard, the electrical inspection preparation before installation is also specified in detail. It is required to check whether the electrical connection line of the water tank is loose, and check whether the 3C certification and warning signs are clear and correct. Check whether the capacity of the user's wire, electric meter and leakage protector can meet the requirements of the water tank to be installed, and check whether the grounding of the user's power supply and the socket meet the installation requirements, etc. Inspection of these items must be carried out by professionally qualified electrical installers.

4. The window of the electric heater of the buffer hot water storage tank shall have reliable waterproof measures. Some of the buffer hot water storage tanks used in the coal-to-electricity conversion in the north will be installed outdoors. If the electrical window does not have good waterproof measures, once water penetrates into the electrical connection line area, it will cause leakage, power failure or even the entire electrical line burned. , A serious accident may cause electric shock.

5. High temperature protection measures for electric heaters: For the bipolar high temperature protection of electrical parts, there are strict mandatory regulations in the GB4706.32 standard. This article introduces the standard configuration method for the actual situation of the water tank during the installation process of coal-to-electricity in the northern area: the high temperature protection device of the electric heater is composed of "automatic reset thermostat + manual reset thermostat + connection line" , Among them, the temperature of the automatic reset thermostat is recommended to be selected between 50℃~65℃, and the temperature of the manual reset thermostat is recommended to choose between 65℃~85℃ (not more than 90℃), and the insulation layer is recommended for the connection line. The cross-sectional area of the wire body is 2.5mm2. Such a combination can meet the requirements of use and meet the 3C standard.

6. Reasonably use the power granted by the standard. The standard 4.4.6 stipulates: if the installation requirements of the water tank to be installed cannot be met, the installer should clearly inform the user and request rectification; if the rectification cannot be made, the installation should be refused. This is not only the power conferred by the standard, but also the guidelines that the installation and acceptance personnel should follow. Therefore, the manufacturing and installation process of our buffer hot water storage tank must be operated and executed in strict accordance with the established standards.

Five, summary

To sum up, there are many methods and essentials in the installation and commissioning process of the buffer hot water storage tank, especially the installation and commissioning methods. We also need the elites of our industry to continuously dig and sum up experience, but no matter what method we adopt For manufacturing and installation, we cannot easily break through the permissions granted by the associated standards.

As far as the group standard T/CECA-G0014-2017 "Code for the Installation of Buffer Hot Water Storage Tanks for Air Source Heat Pump Heating Systems" released on June 20, 2017 is concerned, the installation of buffer hot water storage tanks lacks national and industry standards. , The installation method and acceptance rules of the product in the market are not uniform, which caused the heating system engineering market to be compiled under the condition that the engineering market is not standardized.

We have reason to believe that with such a standard, the buffer hot water storage tank has a guiding direction during the installation and manufacturing process, and at the same time, it also restricts some irregular behaviors; it not only guides the standardized installation of enterprises, and guarantees product performance and quality, It can further promote the healthy development of the air source heat pump heating industry.