Mechanical seals are used in centrifugal pumps to keep water or any liquid from making contact with the delicate parts of the machine. They are situated on the shaft of the motor. Regular maintenance of these seals is needed to ensure there are no leaks. This article teaches you how to replace the mechanical seal.

2.1 Turn off the Power

If the centrifugal motor is in motion, turn it off. Shut off the main power supply. Ensure that there is no possibility of the machine starting up, once you get to work

Figure 1: Turn off the power.

2.2 Cut the Plumbing

Cut the plumbing tubes connected to the centrifugal pump. You can use a saw to perform this action. Once disconnected, you are free to set the pump on a table or the floor, wherever you are comfortable.

Figure 2: Cut the plumbing.

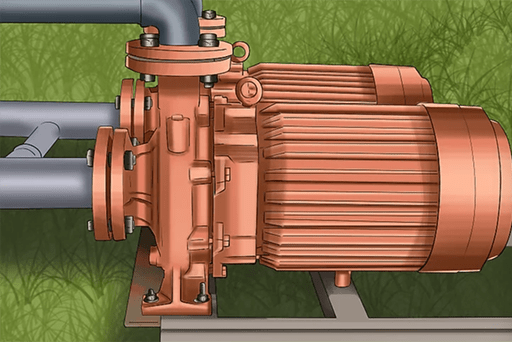

2.3 Disconnect the Pump

Using a wrench, unscrew the bolts holding the pump housing in place. Carefully disconnect and detach the pump located beyond the housing. Keep these bolts safe. You will need it later to reattach this setup.

Figure 3: Disconnect the pump.

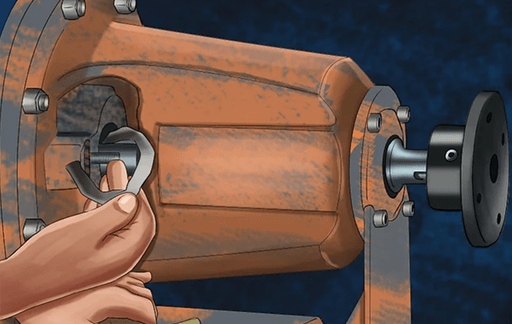

2.4 Dismantle the Centrifugal Pump’s Impeller

The seal is located on the shaft behind the impeller. To detach the shaft, first hold the shaft in place using a wrench. Then unscrew the impeller by rotating it.

Figure 4: Dismantle the centrifugal pump’s impeller.

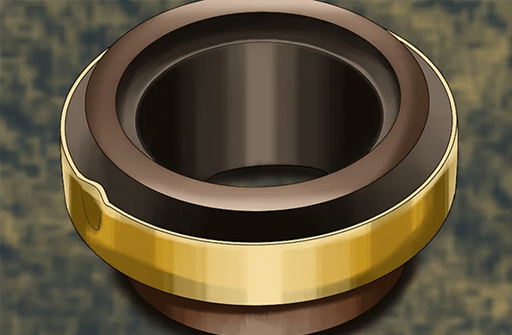

2.5 Remove the Seal

Part of the seal will be attached to the impeller, while the other part will be attached to the motor shaft. Slide the seal off from both these places.

Figure 5: Remove the seal.

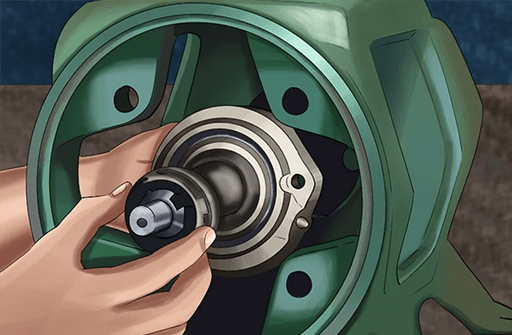

2.6 Replace the Seal

Slide a mechanical seal along the shaft of the motor. Note that the front face of the shaft is extremely sensitive, even to the oils secreted by the fingers. Make sure that you don’t touch the face.

Figure 6: Replace the seal.

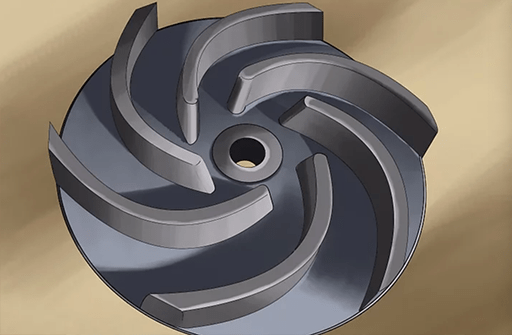

2.7 Screw on the Impeller

With the help of a wrench, hold the motor shaft. Screw on the impeller.

Figure 7: Screw on the impeller.

2.8 Reconnect the Pump

Using a wrench and the bolts from Step 3, reattach the pump and the motor.

Figure 8: Reconnect the pump.

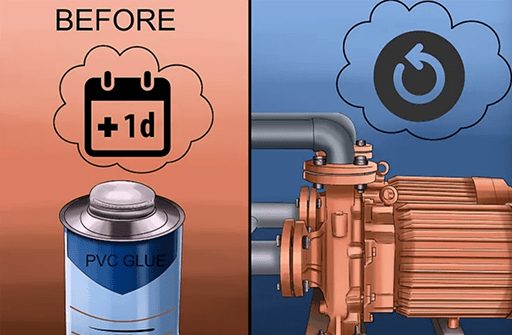

2.9 Reconnect the Centrifugal Pump

Place the reconnected system back into the plumbing. Reconnect the plumbing tubes with the help of industrial strength PVC glue and primer.

Figure 9: Reconnect the centrifugal pump.

2.10 Restart the Machine

After reattaching the plumbing to the centrifugal pump, the PVC glue and primer takes a minimum of one day to dry off completely. Start the machine after a day.

Figure 10: Restart the Machine.

Related Info

Components and Types of Mechanical Seals6 Reasons for Why Mechanical Seals Fail

Proportional Valve Types for Different Applications

What is A Mechanical Sealing