Figure 1: Lubrication is a common solution to reducing gear noises.

During gear transmission, gears scrape and contact each other, and repeatedly, resulting in noises. A long time of such noises would not only affect the production environment, but also harm the health of the operators. Therefore, it is very important to find a reasonable way to reduce gear transmission noise. First, the various specific reasons for the noises will be analyzed.

1. Potential Reasons for the Noises

1.1 Overly Fast Vibration of Gears

The overly high speed of vibration of the gears can influence the frequency of the vibration and cause noises.

1.2 Noises from Resonance

The resonance generated by the gear transmission is based on the fact that the vibration generated by the rigidity differences of the gears themselves and that by the friction between the gears are at the same frequency. And such resonance brings noise.

Figure 2: Resonance rotational speed of driving gear from impulse excitation.

1.3 Rough Gear Surfaces

As we all know, if two objects are smooth, the vibration caused by friction is small. Also, the vibration frequency and high-frequency waves are small, and the noise is naturally small. However, the surface of many gears is too rough and the friction surface is large causing high vibration frequency and larger and more noises.

1.4 Wrong Lubrication

The traditional method of using lubricant is to inject a large amount of lubricant on the gear surface to reduce friction, but this has little effect on noise reduction. In fact, one should adopt the correct method to reduce noises: fully injecting the lubricant into the gear.

2. How to Prevent or Reduce Noises?

In general, gear transmission noises can be attributed to load, vibration frequency, gear friction, etc. Therefore, these points should be focused on when preventing or reducing gear noise.

2.1 Choose Gears according to the Product Weight

The load here mainly refers to the production weight that the old gear can bear. The selection of gears for the corresponding product is determined by the production weight that the product can bear. That is, exchange the gears appropriately according to the weight required by different products, so as to avoid noise caused by some gears that cannot bear the corresponding weight during the transmission process.

2.2 Reduce the Vibration Frequency

Figure 3: The sound pressure changes at different vibration frequency.

Due to the high friction and high speed between some gears, the vibration speed is too fast, resulting in noises. In the design of gears, one should pay attention to the speed of the gears, i.e., to specify the rotations of running within a certain period of time, rather than allowing the gears to rotate too quickly.

2.3 Reduce the Friction

As mentioned above, in case of high friction and large vibration between the gears, the corresponding noise will be very large. To reduce friction between gears, gears with smooth surfaces, instead of rough and frictional gears, should be selected. In addition, lubricants can also be injected into the gears to improve efficient operation between the gears.

2.4 Lubricate Correctly

As for reducing noise through gear lubrication, we should not only start from the selection of lubricants, but also innovate gear lubrication methods and save lubricants.

Studies have shown that centrifugal lubrication is one of the methods that can effectively reduce gear noises. First you need to check the gearbox within the specified time, and replace the gears with serious damage or of degraded quality in time. Then, on this basis, drill a small hole in the bottom of the gear. The centrifugal force allows the lubricant to be injected through the small hole and the used lubricant waste to be removed.

Through this method, effective friction between the gears can be achieved, avoiding the noises caused by poor lubrication.

2.5 Correct the Tooth Profile.

The tooth profile error causes the tooth crest of the gear to mesh, and the meshing accuracy is poor. In order to improve the meshing accuracy, the tooth profile correction method can help to eliminate the noise of the gear effectively. First, coat the gears with red lead powder for meshing. Then correct the meshing points of the gears so that the meshing points of the gears are distributed as close as possible to the reference circle to improve the meshing accuracy.

Figure 4: Gear meshing error.

In addition, the helical gear has a smooth transmission, less meshing impact, and is not prone to resonance. Therefore, changing the spur gear transmission to the helical gear transmission is also an important method to reduce the noise of the gear transmission.

Related Info

How to Maintain a Pressure Transmitter?What is a Smart Pressure Transmitter?

Characteristics of Smart Pressure Transmitters

What is a Gear Reducer?

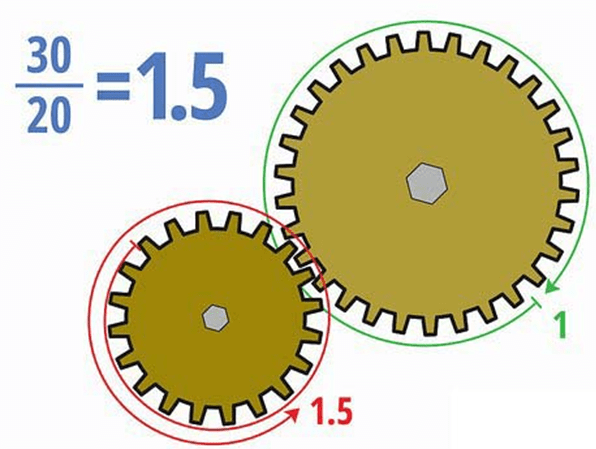

What is Gear Ratio?