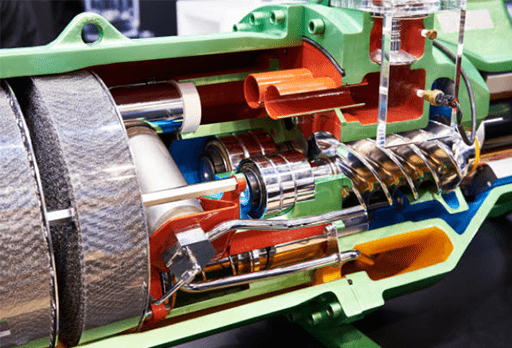

Figure 1: The cut section of a screw air compressor.

The screw air compressor adopts a single power connection and compressed air connection, and a built-in cooling system, which greatly simplifies the installation process.

Screw air compressors consistently provide high-quality compressed air for various industries with its advantages of high performance, high efficiency, high reliability.

So the daily maintenance of them is important to the users. This article will list some methods for the repair and replacement of components.

1. Intake Air Filter Maintenance

The air filter is a part to sieve the dust and dirt. The filtered clean air enters the screw rotor compression chamber. The screw compressor internal clearance is only allowed to filter out the particles within 15u.

If the air filter is blocked and damaged, lots of particles larger than 15u enter the inner circulation of the compressor, which will not only greatly shorten the service life of the oil filter and the oil mist separator, but also lead to particles directly entering into the bearing cavity, accelerating bearing wear, increasing the rotor clearance, and reducing the compression efficiency.

You should maintain the air filter once a week, unscrew the gland nut, and take out the air filter. And then you use compressed air of 0.2 Mpa - 0.4 Mpa to blow the dust particles on the outer surface of the air filter from the inner cavity, and use a clean cloth to clean the booty on the interior wall.

When installing the air filter, you should notice that the sealing ring in the front and the end face of the air filter shell are contacted tightly. The maintenance of the inlet air filter of the diesel engine driven air compressor should be carried out simultaneously with the air filter of the air compressor, and the method is the same.

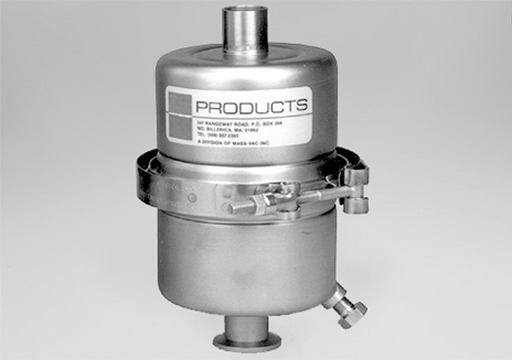

Figure 2: The intake air filter.

You should replace the air filter after using 1000-1500 hours under normal conditions. It is recommended to replace the air filter every 500 hours for use in harsh environments, such as industries of mines, ceramics factories, cotton mills, etc.

When cleaning or replacing the air filter, you should make the parts closed one by one to prevent impurities from falling into the intake valve. In daily use, it is necessary to frequently check whether the intake expansion pipe is damaged or flattened and if the connection between the expansion pipe and the air filter inlet valve is loose and leaked. If these failures occur, you should repair or replace the components as soon as possible.

2. Replacement of the Oil Filter

After running for 500 hours, the new compressor should be replaced with the oil filter. You should remove the oil filter with a special wrench. It is best to add screw compressor oil before installing the new filter. After installing it, you should tighten the oil seal to the oil filter seat.

It is recommended to replace the filter every 1500-2000 hours. You are supposed to replace the oil filter when changing the compressor oil. The replacement cycle should be shortened according to the actual conditions.

It is strictly prohibited to keep using the oil filter after the expiration date. Otherwise, due to the serious blockage of the filter and the pressure difference exceeding the bearing limit of the bypass valve, the bypass valve will automatically open, leading to a large number of dust and particles entering the screw main engine with the oil, which may cause serious damage to the compressor.

The replacement of the oil filter of the diesel engine driven screw air compressor should follow the relevant requirements, and the replacement method is similar to that of a screw oil filter.

3. Maintenance and Replacement of the Oil Mist Separator

Figure 3: An oil mist separator.

The oil mist separator is a component used to separate the lubricating oil and the compressed air. Under normal operation, the service life of the oil mist separator is around 3000 hours. But the quality of the oil and the filtration accuracy of the air will have a great impact on the service life of the oil mist separator.

Note that the maintenance and replacement cycle of the air filter must be shortened in a harsh environment, and a cabin air filter can be installed if necessary.

The oil mist separator must be changed when it expires or if the pressure difference exceeds 0.12 Mpa. Otherwise, it will cause the motor to overload and the oil mist separator to damage.

* How to change the oil mist separator

Remove the pipe fittings installed on the oil and gas barrel cover. You should take out the return pipe stretched into the oil and gas barrel and on the barrel cover, and remove the fastener of the top cover.

After removing the top cover of the oil barrel, you should take out the oil mist separator. Remove asbestos pad and dirt from upper cover. When installing the new oil mist separator, you should staple upper and lower asbestos pads, and align them carefully.

After that, you should put back the upper cover, the return pipe, and the control pipes as original, and check the machine for leakage.

4. Screw Compressor Oil Maintenance and Replacement

The quality of screw compressor oil has a great influence on the performance of the oil-injected screw compressors. The quality oil has the advantages of oxidation stability, rapid separation, good foam removal performance, high viscosity, and anti-corrosion performance. Therefore, users must use special screw compressor oil.

The first oil change will be carried out after 500 hours of run-in period of the new compressor, and then the oil should be changed every 2000 hours. You’d better change the oil filter when replacing the oil. The use in harsh environments will shorten the replacement cycle of the oil.

* Replacement method

First, you should start the air compressor to run for 5 minutes, so that the oil temperature rises to over 50°C, and the oil viscosity decreases.

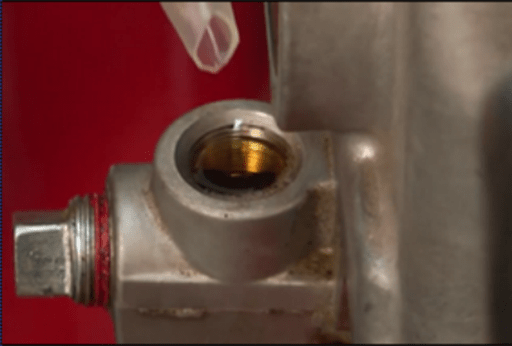

Stop the compressor. When the pressure in the barrel reaches 0.1 Mpa, you should open the oil drain valve at the bottom of the barrel and connect it to the oil storage tank. The oil drain valve should be slowly opened, so as to avoid the lubricating oil splattering.

Close the oil drain valve after the lubricating oil becomes drops. You then unscrew the oil filter, discharge the lubricating oil in each pipeline at the same time, and replace the new oil filter.

Figure 4: The oil drain valve on the compressor.

Open the screw plug on the oil port, and inject new oil, making the oil level within the range of the marking scale. And then you tighten the screw plug and check whether there is leakage.

Lubricating oil must be regularly examined in the process of use. If you find that the oil level is lower than normal, you should timely supplement it. In addition, you are supposed to discharge the condensate once a week, and on hot days you should drain it once every 2 or 3 days.

If the compressor is shut down for more than 4 hours, you should open the oil drain valve without pressure in the oil tank and drain the condensate. If you see the compressor oil flowing out, please close the valve as soon as possible.

It is strictly forbidden to mix lubricating oils of different brands for use. Plus, you should avoid using lubricating oils for extended periods of time. Otherwise, the quality of the lubricating oil will go bad, and the lubrication performance will be bad. It will tend to cause the high-temperature malfunction of the air compressor, leading to the spontaneous combustion of the oil.

Related Info

Air Compressor Troubleshooting and SolutionsList of Problems and Solutions for Screw Compressors

How to Reduce Noise of Air Compressor?

How to Prevent Air Compressor High Oil Consumption

Factors Affecting Air Compressor Performance in Long-Period Operation