Compressed air technology is moving towards an era of high efficiency

-2019 compressed air technology development trend report

Compressed air is the most widely used energy source in industry and commerce, in addition to electricity. Its wide application stems from its easy operation, fast speed, high power density, safety and good compatibility, but its higher cost cannot be ignored...

Compressed air is the most widely used energy source in industry and commerce, in addition to electricity. Its wide application stems from its easy operation, fast speed, high power density, safety and good compatibility, but its higher cost cannot be ignored. Therefore, it is important to understand and make the best use of all the savings potential. The fastest and most effective way to achieve this goal is to solve the problem of leakage. Sealing without leakage is generally impossible for compressed air users. About 30% of compressed air escapes into the environment unintentionally.

Regardless of the air compressor station equipment or the update and upgrade of the control software, Boge will start with the audit and inspection of the compressed air system to understand the current actual status of the air compressor station, and install the box-type measuring instrument on the user site, and use two It collects and records data on the compressed air usage and control status of the user’s air compressor station within a week. Finally, experts estimate the potential for optimization based on the collected data. The focus of optimization is the utilization of waste heat, the use of higher-level control systems, the adjustment of the speed of each air compressor (frequency conversion), and the use of more efficient compressed air preparation.

Compressed air distribution network

Reasonable compressed air distribution network is very important to improve the economic efficiency of compressed air utilization. The German Machinery Manufacturing Association VDMA drafted the industry standard 15391-1 "Compressed air distribution-economic and safety planning-Part 1: Planning and design and new installation of equipment" in the summer of 2018. This part has a total of 86 pages and is a general compressed air system The designer provides rich content auxiliary design tools.

Through the examples introduced in this article, users can clearly understand the importance of compressed air distribution networks. Bode Chemie can reduce more than 300,000 kW of electricity consumption and 160 tons of CO2 emissions per year through the technical transformation of the air compressor station. For example, the decentralized compressed air supply network of a company originally distributed in 2 plant buildings (with a total of 3 air compressors installed) has also been completely rebuilt. The core of the new compressed air system is to place all the air compressors in one room for control and management, and use the adjustable speed, oil-injected and lubricated GA 45 VSD screw air compressor developed and produced by Atlas. The original three air compressors were also moved to the new air compressor station and incorporated into the new compressed air supply system. Therefore, the entire compressed air supply system has a high peak buffer performance and required redundant reserves. The technical transformation measures adopted have also reduced the working pressure from the original 0.95MPa to 0.7MPa. Compression and heat generation are closely related. As this technical transformation has once again confirmed, the technical principle of "compressed air + thermal power plant" developed by altAIRnetive is to use a natural gas-burning internal combustion engine to generate working power to drive an air compressor. The mechanical power is 26-300kW, and the initial flow temperature is 108℃, which effectively combines air compression and production heat energy. The advantage is that there is almost no efficiency loss, because almost all the heat generated when the air is compressed is used in the production process instead of being released into the ambient atmosphere like a traditional air compressor. The heat generated by the combination of the heat generated by air compression and the heat generated by the internal combustion engine produces a thermal efficiency equivalent to that of a modern heating system. According to the supplier, compressed air is now almost "zero loss" used, and the investment payback period for the entire equipment is less than two on average. Years and a half.

Green power of compressed air

In addition, the technical model of "compressed air + energy storage power plant" (referred to as CAES) is also very important. Although our understanding of compressed air + energy storage power generation is not comprehensive enough, this technology can store green electricity for a long time and economically. Atlas Company said that its working principle is equivalent to a pumped storage power plant. When the power supply is surplus, the air compressor compresses the air into compressed air with a high compression ratio. Between 1~20MPa, according to different types of this system, different pressures can be reached. At the same time, the air compressed in this way is temporarily stored in a suitable container.

When using these compressed air, the stored compressed air is used to drive the turbo unit (turbine plus generator) to reduce pressure, and the generated electricity can be fed to the grid. In order to be able to directly apply this new technology in practice, Atlas has cooperated with community wind farms in the Schleswig-Holstein region to summarize the key data of the A-CAES (adiabatic) compressed air energy storage power generation system. The conclusion is that this system is more economical than other power storage systems. In addition, A-CAES also has the advantage of theoretically unlimited recycling. Traditional power storage methods will cause the aging of batteries and hydrogen fuel cells, and lose the ability to store power due to their aging, thereby reducing the performance of stored power. However, the service life of the A-CAES system is only affected by mechanical parts and The impact of small shrinkage factors.

divergent air compressor network

Boge company also provides brand-new detection and analysis services, and regards this detection and analysis service as a part of the company's continuous improvement plan (referred to as CIP). This is done to enable the networked air compressor to continuously provide data on the operating conditions of the air compressor detected by the sensors, and then pneumatic technology software can judge these data. For example, when an abnormality occurs in the power unit of an air compressor, the user's mobile terminal device will receive a prompt message. This software system can also provide forecasts of the working conditions of the air compressor, that is, warnings of possible wear and tear of the air compressor.

CIP continuously verifies the mechanical performance of the air compressor and provides the corresponding data to the manufacturer. Manufacturers analyze these data to find out the potential for improvement and optimization, for example, to find out measures to further reduce energy consumption. Within the framework of CIP, Boge provides users with free air compressor hardware and software upgrade services. Aerzen company recently launched the technical service of energy efficiency analysis of AERaudit sewage treatment plant. 80% of the total energy demand of the sewage purification treatment plant is used for biological aeration, because there are high energy-consuming blower stations there. Nowadays, users can collect real-time energy consumption data for ventilation and aeration with a mobile measuring device. This instrument can detect data such as flow, system pressure, temperature and power consumption in real time, and record it according to the load of the sewage purification equipment. On the basis of these data, Aerzen will provide users with more efficient energy-saving solutions.

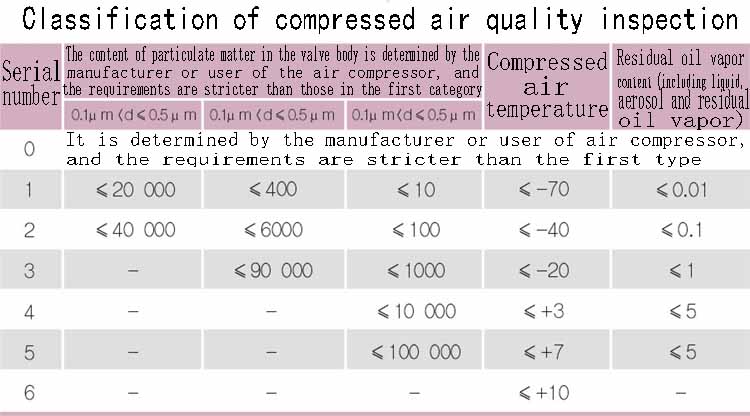

According to the ISO 8573.1 standard, Aerzen uses 3 digits to indicate the quality of compressed air, the first digit indicates the concentration of particles in the compressed air, the second digit indicates the moisture in it, and the third digit indicates the residual in the compressed air Oil vapor content. For the detection of residual oil vapor, Beko is expanding its product range in the field of measurement technology. Compared with the previous testing instruments, the new Metpoint OCV compact tester has a shorter test cycle and modular structure design. Therefore, the new instrument has the characteristics of compact device, convenient installation and use, and more powerful performance. It also has higher detection accuracy of compressed air residual oil vapor.

In some production processes, for example, ACU Pharma und Chemie requires no residual oil vapor in the compressed air. It uses a special jet mill, which requires very clean and dry compressed air to achieve the best micronization process. The company used three screw air compressors lubricated with lubricating oil in the past, and used a complex oil-free compressed air treatment system that combines centralized and decentralized control, including an activated carbon adsorber that absorbs residual oil vapor. When expanding the air compressor station, the company updates all air compressors for the purpose of economical, flexible and highly reliable production of oil-free and dry compressed air. After careful consideration, 4 DH-type oil-free air compressors developed and produced by Gardner Denver were selected, including a compressed air treatment system. The brand-new air compression technology adopted by the DH series air compressor is trustworthy. The lubrication, sealing and cooling required for the cylinder of the air compressor are all done with water. This not only achieves a clean, oil-free compression process, but also enables efficient production of compressed air.

Low loss design principle

Air compressor stations are usually designed in accordance with the modular principle. They use IE3 and IE4 energy-saving motors to ensure basic compressed air supply. During peak air consumption, peak load air compressors can be flexibly used to meet the increase Demand for compressed air. In the future, high-efficiency air compressors will be used to ensure air supply under partial load conditions. The ASD series of screw-type air compressors with adjustable speed developed and produced by Kaeser provide high performance and working reliability, with a volumetric flow of 3.15~5.5m3/min, low energy consumption and small footprint. This series of air compressors uses a synchronous reluctance motor developed and produced by Siemens. Under partial load conditions, the efficiency of this motor is 10% higher than that of an induction motor. The energy-saving variable frequency motor can also drive the RSF 87D screw air compressor developed and produced by Renner. The core component of this air compressor is the compression module, which can be optimally matched with other air compressor components of modular design Together. Therefore, the entire air compressor can be designed and manufactured accurately according to the user's requirements for compressed air.

Finally, it should be noted that when purchasing an air compressor, just focusing on the purchase cost will deviate from the most advantageous solution, and the sum of the various efficient components may not necessarily achieve a reasonable overall benefit.