Classification of air-conditioning compressors The air-conditioning compressor plays the role of compressing and driving the refrigerant in the air-conditioning refrigerant circuit. The working circuit is divided into an evaporation area (low pressure area) and a condensation area (high pressure area). The indoor unit and outdoor unit belong to the high-pressure or low-pressure area (depending on the working state), and the compressor is generally installed in the outdoor unit. The compressor draws the refrigerant from the low-pressure area, compresses it, and sends it to the high-pressure area for cooling and condensation. The heat is emitted into the air through the fins. The refrigerant also changes from a gaseous state to a liquid state, and the pressure increases. The refrigerant then flows from the high-pressure area to the low-pressure area, and is ejected into the evaporator through the capillary. The pressure drops suddenly, and the liquid refrigerant immediately becomes gaseous, absorbing a large amount of heat in the air through the heat sink. In this way, the machine continues to work, it will continue to absorb the heat at one end of the low pressure area into the refrigerant, and then send it to the high pressure area to distribute it to the air, which plays a role in regulating the temperature Working principle of air-conditioning compressor Classification of air compressor Air compressor is the main body of the air source device. It is a device that converts the mechanical energy of the prime mover (usually an electric motor) into gas pressure energy. It is a pressure generating device for compressed air. There are many types of air compressors, which can be divided into positive displacement compressors and speed compressors according to the working principle. The working principle of a volumetric compressor is to compress the volume of gas, increasing the density of gas molecules per unit volume to increase the pressure of compressed air; the working principle of a speed compressor is to increase the speed of movement of gas molecules, so that the kinetic energy of gas molecules Converted into gas pressure energy, thereby increasing the pressure of compressed air. The working principle of piston air compressor In pneumatic transmission, the volume type piston air compressor is usually used. Two typical structures are introduced here to help understand the working principle of air compressors. Figure 3.33 (animation) and Figure 3.34 (animation) give the working principle of vertical and horizontal air compressors respectively. The center line of the cylinder of the vertical air compressor is perpendicular to the ground, and the center line of the cylinder of the horizontal air compressor is parallel to the ground. The rotary motion of the prime mover (electric motor or internal combustion engine) is converted into a reciprocating linear motion of the piston by the crank connecting rod mechanism. The air intake and exhaust processes in the air compressor are similar to the oil suction and pressure processes of the hydraulic pump, and will not be repeated here. The choice of air compressor The choice of air compressor is mainly based on the working pressure and flow rate of the pneumatic system. The working pressure of the air source should be about 20% higher than the highest working pressure in the pneumatic system, because the loss and partial loss of the gas supply pipeline must be considered. If the working pressure requirements are low in some parts of the system, a pressure reducing valve can be used to supply gas. The rated discharge pressure of the air compressor is divided into low pressure (0.7~1.0MPa), medium pressure (1.0~10MPa), high pressure (10~100MPa) and super high pressure (above 100MPa), which can be selected according to actual needs. With the development of the domestic economy, my country's air compressor design and manufacturing technology will also develop by leaps and bounds, and the technical level in certain aspects has also reached the international advanced level. However, there are still some gaps with the international advanced level in some aspects. I hope that the users of air compressors can be realistic in the selection of models, combined with the needs of the enterprise, choose economical, reliable, efficient and environmentally friendly air compressors to avoid problems such as machine maintenance and increased costs caused by incorrect selection of models. For various types of air compressors, many users cannot have a precise understanding of the selection of air compressors. Sometimes it is because they cannot fully understand the efficiency and performance of different air compressors, which makes it impossible to choose reasonably. It is impossible to choose a reliable, efficient and energy-saving air compressor model. Now we will give a brief introduction to the advantages and disadvantages of several commonly used air compressor models and their scope of application, hoping to make a reference for users when choosing an air compressor. According to the different gas methods of air compressors, air compressors are usually divided into two categories, namely, volumetric and power (also known as speed) air compressors. Due to the different structural forms of volumetric and power compressors, the following classifications have been made:

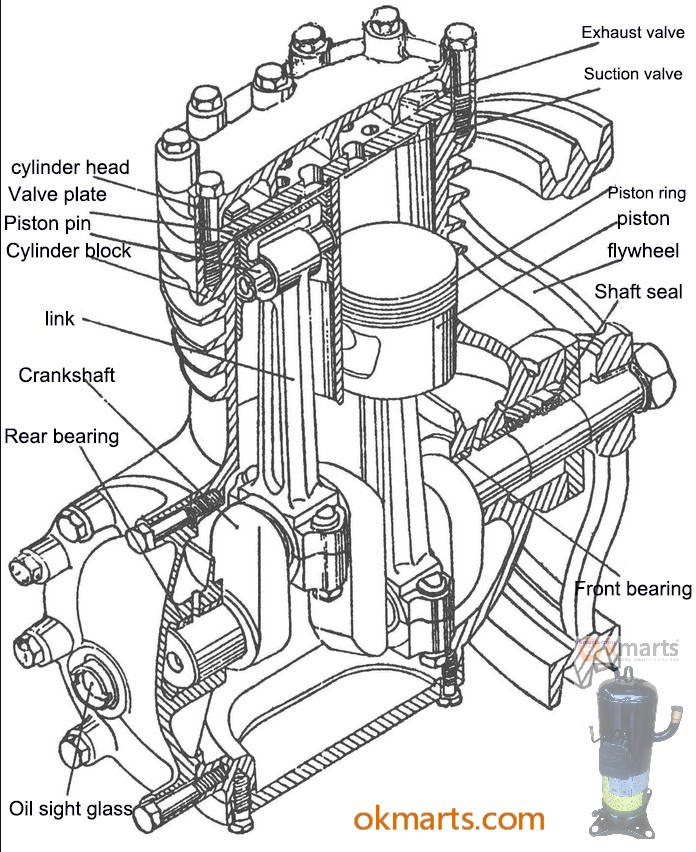

Mobile air compressor Mobile air compressor is a kind of power type air compressor, in which there are one or more rotating impellers (the blades are usually on the side) to accelerate the gas, and the main air flow is radial. Power type air compressors are divided into jet type and turbine type air compressors. Centrifugal type air compressors belong to turbine type air compressor units. In the centrifugal air compressor, the impeller rotating at a high speed gives the centrifugal force of the gas and the gas diffusion in the diffuser channel to increase the gas pressure. Scope of application In recent years, the chemical industry and large-scale chemical plants have been established one after another, making centrifugal air compressors a key machine for compressing and transporting various gases in chemical production, occupying an important position. With the achievement of gas dynamics research, the efficiency of centrifugal air compressors has been continuously improved, and due to the high-pressure sealing, the processing of small flow narrow impellers, and the development of key technologies such as multi-oil wedge bearings, the high pressure of centrifugal air compressors has been solved. A series of problems in the development of a wide flow range have greatly expanded the application range of centrifugal air compressors, so that it can replace reciprocating air compressors in many occasions and greatly expand the application range. Some basic chemical raw materials, such as propylene, ethylene, butadiene, and benzene, can be processed into important chemical products such as plastics, fibers, and rubber. In petrochemical plants producing this basic raw material, centrifugal air compressors also occupy an important position and are one of the key equipment. In addition, in other industries such as petroleum refining and refrigeration, centrifugal air compressors are also extremely critical equipment. The principle of the centrifugal air compressor: the centrifugal air compressor is driven by the impeller to rotate the gas at high speed, causing the gas to generate centrifugal force. Due to the diffused flow of the gas in the impeller, the flow velocity and pressure of the gas after passing through the impeller are increased and continuous To produce compressed air. The centrifugal air compressor belongs to the speed type compressor. When the gas load is stable, the centrifugal air compressor works stably and reliably. The structural characteristics of the centrifugal air compressor: the centrifugal air compressor unit has a simple structure and reliable operation; the main components of the centrifugal air compressor, the aerodynamic part, the interstage cooler, the overall transmission device, the lubrication system and the operation control can be manufactured Guaranteed to provide reliable performance; in the compressed air channel, the centrifugal air compressor does not have any parts that need to be lubricated; the centrifugal air compressor's precisely balanced flexible disc coupling reduces vibration to a minimum and does not require connection The lubricating oil of the compressor can also provide other connection methods; the compact set base of the centrifugal air compressor integrates the frame, the intercooler and the lubricating oil tank, thus having excellent torsional rigidity. The application of centrifugal air compressors: centrifugal air compressors are widely used in automotive, chemical, pharmaceutical, mining and air separation industries. Centrifugal air compressors also have good development prospects in these industries. main advantage: 1. Large flow, high power, conducive to energy saving. The medium flowing through the impeller of the turbomachine has been continuous. The volume of the cylinder is large, and the impeller can rotate at high speed. Therefore, the exhaust flow and the generated power of the turbomachine can be greatly increased. Therefore, the exhaust of the centrifugal air compressor is uniform, and the air flow has no pulse. 2. The structure is compact, the sealing effect is good, the leakage phenomenon is small, and the size is small, so the footprint and weight of the unit are much smaller than the piston air compressor of the same air volume. 3. The operation is stable and the operation is reliable. Therefore, it has a high operation rate, a flat performance curve, a wide operation range, and low maintenance costs and personnel. 4. The compression process of the centrifugal air compressor can be absolutely oil-free and does not require lubrication in the machine, which is very important for the production of many industries. 5. Few wearing parts, long running period, few and simple moving parts, and low manufacturing precision, so its manufacturing cost is relatively low and its reliability is high. Easy to realize automation and large-scale. Main disadvantages: 1. At present, the centrifugal air compressor is not suitable for occasions where the air volume is too small and the pressure ratio is too high. 2. The stable working area of the centrifugal air compressor is narrow. Although its air volume adjustment is more convenient, it is less economical. The air flow speed is large, and the parts in the flow channel have a large friction loss. 3. The efficiency of centrifugal air compressors is still generally lower than that of piston air compressors. The adaptability of the operation is poor, and the nature of the gas has a great influence on the operation performance. When the unit starts, stops, and runs, the load changes greatly. 4. The centrifugal air compressor has a high speed, which may produce mechanical vibration. In terms of operating characteristics, there will be a surge phenomenon, which is extremely harmful to the machine. 5. The operation is relatively complicated, the gear box is noisy, the technical content of the equipment is high, and the maintenance cost is relatively large. Piston air compressor Piston air compressor is one of the most common volumetric air compressors. Taking Fusheng Air Compressor as an example, it uses the crank connecting rod mechanism to change the rotary motion of the driving machine into the reciprocating motion of the piston. The piston and the cylinder together form the working chamber of the air compressor, relying on the reciprocating movement of the piston in the cylinder, and by the automatic opening and closing of the intake and exhaust valves, the gas periodically enters the working chamber of the cylinder for compression and discharge. The piston air compressor is mainly composed of three parts; the motion mechanism (crankshaft, bearing, connecting rod, crosshead, pulley or coupling, etc.), working mechanism (cylinder, piston, air valve, etc.) and the fuselage. In addition, there are three auxiliary systems: the lubrication system, the cooling system and the regulation system. The motion mechanism is a crank connecting rod mechanism, which changes the rotary motion of the crankshaft to the reciprocating motion of the crosshead. The fuselage is used to support and install the entire motion mechanism and working mechanism. The working mechanism is the main component to realize the working principle of the air compressor. Scope of application Piston air compressor belongs to a reciprocating air compressor, the pressure level belongs to medium pressure, high pressure, ultra high pressure level, suitable for high pressure occasions, the flow rate is medium and small flow range is mainly suitable for medium and small displacement , High pressure occasions. Working principle: In pneumatic transmission, volumetric piston air compressors are usually used. The piston-type air compressor uses the crankshaft to drive the reciprocating motion of the piston to compress the gas in the cylinder cavity and continuously generate compressed air. Piston air compressors are volumetric air compressors. The working principle and characteristics of this model are limited. In order to stabilize the air supply, the general piston air compressors are equipped with air storage tanks. The following figure is a structural isometric view of a vertical two-cylinder piston crank connecting rod type refrigeration compressor.

Operation of piston refrigeration compressor Preparations before starting View running log By checking the operation record, understand the reason and time of refrigeration compressor shutdown, and determine the number of startups. If the normal stop can be driven by the duty team leader, if the machine is shut down or the machine is regularly repaired, it should be checked whether the machine has been repaired and should have a test record after the repair. If the continuous downtime exceeds one month or after the machine is overhauled, the workshop director or technicians must be present for the first start-up for the commissioning. Check refrigeration compressor 1. Check that there are no obstacles in the running parts of the refrigeration compressor and motor, and whether the safety protection cover is in good condition. 2. Check the crankcase pressure, if it exceeds 0.2Mpa (gauge pressure), the pressure should be reduced first. If this happens frequently, the cause should be identified and eliminated. 3. Check the oil surface of the crankcase. If the side cover has only one oil sight glass sight hole, the oil surface should not be less than 1/2 of the sight hole; if there are two upper sight holes, the oil surface should be more than 2/3 of the lower sight glass hole , Less than 1/2 of the viewing hole of the upper glass. 4. Check whether the closing valves of each pressure gauge have been fully opened and whether each pressure gauge is sensitive and accurate, and the damaged gauge should be replaced. 5. Check whether the handle of each pressure energy adjustment device is set to the "zero position". If there is no zero position, it should be set to the position with the smallest number of cylinders. 6. Check whether the water jacket cooling water system of the compressor and the refrigerant water system with refrigerant have been supplied with water. 7. Check whether the pointers of automatic protection devices such as oil pressure relays, high and low pressure relays are adjusted to the required values. Check other equipment 1. Refrigerant liquid pumps (such as ammonia pumps), water pumps, fans on the cooling fan, and the operation parts of the cooling water tower fan should be free of obstacles and can work normally. 2. Check the water tank of the evaporator, the water level of the spray chamber, and the water level of the humidifier should be kept at a certain height. Make sure that there is water at the suction end of the pump. 3. The refrigerant system should be free of refrigerant leakage, if the leakage should be dealt with in advance. 4. Water supply Start the water pump to supply water to the condenser, the water jacket of the cylinder of the refrigeration compressor and the oil pipe in the crankcase. main advantage: 1. Wide applicable pressure range. Because it works on the principle of volume change, it can reach a high working pressure regardless of its flow rate. At present, it has been made into various low, medium, high and ultra-high pressure air compressors. Among them, the working pressure of industrial ultra-high pressure air compressors can reach 350MPa (3500kgf/cm2). 2. Low equipment price, low initial investment, convenient operation and long service life. 3. Because the compression process is a closed process, the thermal efficiency is higher. 4. Strong adaptability, wide range of exhaust volume, and less affected by changes in exhaust pressure. When the medium weight changes, its volume displacement and exhaust pressure change are also small. Main disadvantages: 1. The inertial force is large, and the rotation speed cannot be too high, so the machine is bulky, especially at large displacement. 2. The structure is complicated, there are many wearing parts, the repair work is heavy, and the maintenance cost is relatively high. 3. The exhaust is discontinuous, the pressure of the airflow is pulsating, and it is easy to produce air column vibration. 4. Vibration and noise during operation are high, and the equipment installation requirements are high. Since the piston machinery can only intermittently intake and exhaust, the cylinder volume is small, and the speed of the piston reciprocation cannot be too fast, so the exhaust volume and the power of the piston machinery must be greatly limited. In order to promote the advantages and overcome the shortcomings, the structural parameters tend to high speed and short stroke, making the structure compact. At the same time extend the life of wearing parts such as air valve, sealing element, etc., in order to improve the operating rate. With the development of optimization design theory and computer technology, new prospects have been opened for rational selection of design parameters and improvement of benefits. Rolling piston air compressor Rolling piston air compressor is also called rotor air compressor. It is called rolling piston air compressor or rolling rotor air compressor after adding a set of rings to the original eccentric wheel. It is also referred to as roller air compressor, fixed-piece air compressor or rotary air compressor in my country. This type of air compressor does not require a suction valve, its biggest feature is that it is suitable for variable speed operation, so that the system performance can be improved by frequency conversion control. The rolling piston air compressor includes a cylinder, an air inlet on the cylinder, an exhaust valve, a ferrule in the cylinder that can be moved in a plane, and a slide and a slide spring are arranged between the ferrule and the cylinder. For the eccentric pressure block connected with the shaft, the inner wall of the cylinder and the circumferential and radial directions of the ferrule are blocked and sealed to form a rolling friction contact between the ferrule and the eccentric pressure block, thereby improving the sealing performance and lubrication performance of the air compressor. And volume coefficient, no need to prepare complex lubrication system, can be used effectively without adding lubricating oil in compressed air system. Scope of application: Rolling piston air compressors account for a large proportion of small fully enclosed refrigeration air compressors, and are widely used in room air conditioners, refrigerators and small commercial refrigeration equipment. Working principle: Rolling piston air compressor is composed of rolling piston, gas cylinder, sliding plate and its back spring, eccentric axle and two ends of cylinder and other main accessories. The center of rotation of the eccentric wheel shaft coincides with the center of the cylinder bore. The rolling piston is mounted on the eccentric wheel shaft, and the rolling piston is concentric with the eccentric wheel shaft, so that the outer surface of the rolling piston is tangent to the inner surface of the cylinder. There is a crescent space between them, which constitutes the working chamber of the air compressor. main advantage: 1. The vibration is small, the operation is stable, and the flow rate of the gas in the intake port and the exhaust valve is low. 2. The rolling piston air compressor does not need to install an intake valve, and there is no suction and exhaust muffler, so the flow resistance loss of the intake and exhaust is small, and the volume ratio is high. 3. Fewer wearing parts, simple structure, small size and light weight. Main disadvantages: 1. Since there are some characteristic angles in the working process of rolling piston air compressors, they have an adverse effect on the performance and working life of the air compressor, so it is necessary to consider the characteristic angle as small as possible. 2. The energy loss of the gas in the intake and exhaust ports is large, so the installation of the exhaust valve should be careful. 3. The processing requirements of parts are high, the assembly is complicated, and the maintenance is difficult. Slider air compressor Slide vane air compressor belongs to a type of rotary air compressor. Its axial vane slides radially on the rotor eccentric to the cylindrical cylinder. The air trapped between the vanes is compressed and discharged. There are two situations in the rotary air compressor: one is that the sliding plate is installed in the groove on the cylinder body, because the sliding plate does not rotate with the rotor, it is called a fixed sliding (blade) plate air compressor, that is, the rolling piston is empty Compressor; the other is that the vane is installed in the groove of the rotor and rotates with the rotor. It is called a rotary vane (blade) air compressor, referred to as a vane or rotary vane, rotary vane air compressor. Scope of application: The vane type air compressor is mainly used as an air compressor. The exhaust volume is generally 0.3 ~ 40m3/min, and the market share is low. According to the different lubrication methods, it can be divided into three types: oil dripping, oil injection and oil-free. The sliding vane air compressor is widely used in various compressed air devices, small refrigeration air conditioning devices and automobile air conditioning systems. In the chemical industry and the food industry, oil-free machines can be used to transport or pressurize various gases, and can also be used as a gas source for solid particulate materials. The sliding vane machine can also be used as a vacuum pump. Working principle: The sliding vane compressor uses traditional technology to directly drive at a lower speed. The rotor is a continuously running component with a number of slots cut along its length, in which slides that slide on the oil film are inserted. The rotor rotates in the stator of the cylinder. During the rotation, the centrifugal force throws the slider out of the slot to form a single compression chamber. The rotation reduces the volume of the compression chamber and the air pressure continues to increase. Oil controls the heat generated by the compression, which completes the compression of the air. Because the method adopted is relatively backward, the gas will contain a lot of engine oil. At this time, the oil and gas separator is needed, and it can be put into production after being filtered clean. This equipment is not suitable for high gas accuracy requirements. Industry, there are also the problems of noisy and high maintenance cost of the host. The sliding vane air compressor is mainly composed of three parts: the rotor of the airframe (ie cylinder) and the sliding vane. The outer surface of the rotor is circular with the inner surface of the cylinder. The rotor is eccentrically installed in the cylinder so that the two are tangent, forming a crescent-shaped space between the inner wall of the cylinder and the outer surface of the rotor. The rotor is provided with a number of slide slots, each of which is equipped with freely sliding slides. When the rotor rotates, the slides are thrown out of the slots under the action of centrifugal force, and their ends are closely attached to the inner surface of the cylinder to hold the crescent The shaped space is divided into a number of fan-shaped cells, called primitives. With the continuous rotation of the rotor, the cell volume changes from small to large.

Sliding vane air compressor structure As shown in the picture: the whole machine of the vane compressor looks relatively simple, and almost no parts can be seen. It condenses the air filter, intake valve, oil-gas separator, safety valve, minimum pressure valve, oil filter, temperature control bypass valve, oil return valve and other components in the main unit in the form of modules.

Moving parts The moving parts of a sliding vane compressor include a rotor and sliding vanes. The rotor makes a single rotary motion in the housing, and the inlet and exhaust ports are perpendicular to the axis of the rotor and are not subject to axial forces. The radial force acts directly on the rotor. As shown in the figure on the right, the rotor has high strength and good rigidity, and the radial force received can be ignored. The processing level and installation accuracy of the rotor itself have almost no effect on the efficiency and reliability of the compressor. At the same time its life is not affected by other components. For the rotor, it will never be broken. The sliding part of the other moving part comes into contact with the housing through a layer of oil film and rotates under the drive of the rotor. In fact, the housing is a large sliding bearing, and the rotor and the sliding plate are the shaft. Under the care of the oil film, The slide will never be bad in theory, not to mention that it has a very good compensation capability. So no matter under any working condition, we guarantee its service life exceeds 100,000 hours. The moving parts of screw compressor include rotor, bearing and gear. The inlet and exhaust ports of the screw compressor are horizontal to the axis of the rotor. Under the strong pressure difference between the inlet and exhaust ports and the meshing force of the female and male rotors, the rotor is subjected to both axial and radial forces. The machining accuracy of the rotor itself is high, and the accuracy of the rotor assembly depends on the bearing. Therefore, the life of the rotor is affected by the accuracy of the rotor processing equipment, bearing accuracy, gear box, coupling and other related equipment. The design life of this screw is 100,000 hours, but its service life is difficult to determine due to many factors.

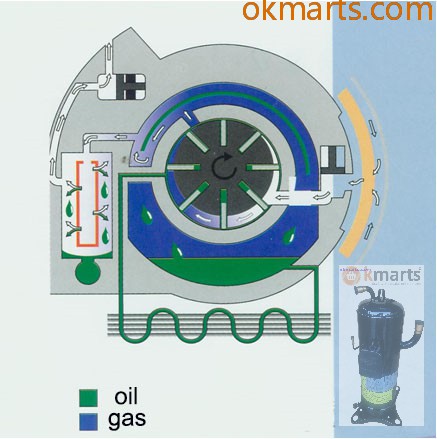

main advantage: 1. Simple structure, few parts, easy processing and assembly, and easy maintenance. 2. Stable operation, low noise, low vibration, and low starting impact. 3. Compact structure, small size, light weight, easy to install in narrow space. 4. Large gas transmission volume, uniform flow rate, small pulsation, no need to install a large gas reservoir. Main disadvantages: 1. The mechanical friction between the slider and the rotor and cylinder is serious, and the wear and energy loss are large. 2. Due to the large wear, the service life and efficiency are low. Scroll type air compressor Scroll type air compressor has developed rapidly in the past ten years, which constitutes a new bright spot in the development of air compressor technology. The scroll-type volumetric rotary air compressor has received more and more attention because of its small size, high efficiency, and smooth operation. It has great application prospects in small air compressors. The emergence of high-precision CNC milling machines has also brought development opportunities to the development of scroll machinery. Scope of application: The field of air-conditioning air compressors is the most suitable field for scroll machinery to be used in air compressors, and it is also the area with the largest output of the current products; because the pressure of scroll air compressors is relatively high, it is also suitable for refrigeration air compressors; Scroll compressors have a large compression process index and are also used for air compression and other gas compression; scroll machinery can also be used as a vacuum pump. Working principle: The scroll air compressor is composed of the main accessories such as the static scroll and the movable scroll, the cross slip ring, the main shaft, the frame, etc. The scroll body or scroll of the static scroll and the movable scroll generally consists of uniform and gradually Open-line configuration, facing each other, and the phase missed 180O. When the scroll air compressor is in operation, the movable scroll performs planar circular motion (around the center of the main shaft) while the main shaft is driven and the phase of the anti-rotation mechanism is maintained. As shown below. A pair of working chambers completes an inhalation-compression-exhaust process. Different vortex turns have different rotation angles during the compression process. The more the vortex turns, the greater the rotation angle. When the outermost suction chamber forms a closed volume and starts to advance toward the center, another new suction chamber begins to form at the same time, and the above process is repeated. Therefore, regardless of the number of scrolls, the air compressor completes the intake and exhaust process once per revolution. Scroll compressor structure Scroll compressor has novel and precise structure, and has the advantages of small volume, low noise, light weight, small vibration, low energy consumption, long life, continuous and stable gas transmission, reliable operation, clean air source and so on. Scroll compressor is an energy-saving compressor in the world today, known as "new revolutionary compressor". The scroll, the main operating part of the scroll compressor, has little wear and therefore has a longer life. It is known as a "maintenance-free compressor." The scroll compressor runs smoothly, has little vibration, and has a quiet working environment. It is also known as "ultra-static compressor". Gaseous refrigerant is compressed in the space formed between the vortex stator, the vortex rotor, and the supporting end cover plate (which is integrated with the stator in the figure). A suction port is provided on the circumference of the vortex stator, and an exhaust port is provided in the center of the end cover.