Compared with ordinary freezers, the cold storage has a larger cooling area. Because of the large cooling area of the cold storage, the power consumption is relatively large. Today, we will introduce to you how to make cold storage more energy-saving. Learning these skills can reduce operating costs and save energy.

1. Reducing the Heat Load of the Cold Storage

1.1 The Thermal Insulation of the Cold Storage

The temperature of the low-temperature cold storage is generally around -25℃, while the outdoor daytime temperature in summer is generally above 30℃, which means that the temperature difference of the inside and outside of the cold storage will be about 60℃. Plus the solar radiation during the day makes the heat load formed by heat transfer from the wall and ceiling to the storage quite large, which is an important part of the heat load in the entire storage.

The thermal insulation performance of the cold storage is enhanced mainly by thickening the insulation layer, applying high-quality insulation layer, and adopting reasonable design solutions.

Of course, if the insulation layer of the cold storage is thickened, the one-time investment cost will increase, but compared with the reduction in the regular operating costs of the cold storage, it is still reasonable from both an economic and technical management perspective.

1.2 Two Common Methods Used to Reduce Heat Absorption of the Outer Surface

One is that the outer surface of the wall should be white or light-colored to enhance the reflective ability. Under the strong sunlight in summer, the temperature of the white surface is 25℃ to 30℃ lower than that of the black surface.

The second is to make a sunshade enclosure or a ventilation interlayer on the outer wall surface.

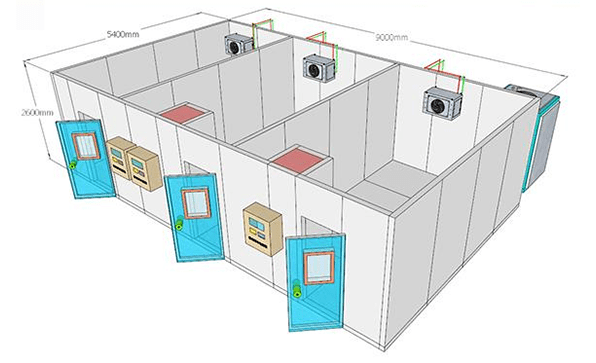

1.3 The Design of the Cold Storage Door

Since people often come in and out of the cold storage to load and unload goods, the storage door needs to be opened and closed frequently. If the insulation work is not done well at the door, a certain heat load will be generated due to the infiltration of high-temperature air outside the warehouse and the heat of the personnel brought in.

You can also choose to install an electric cold storage door and add an air curtainand a sensor-type automatic switch is installed in front of the door.

1.4 Cold Storage Lighting

Use high-efficiency lamps with low heat generation, low power and high brightness, such as sodium lamps. High-pressure sodium lamps are 10 times more efficient than ordinary incandescent lamps, while consuming only 1/10 the energy of inefficient lamps. At present, new LEDs are used as lighting in some more advanced cold storages, with lower heat generation and energy consumption.

2. Improving the Working Efficiency of the Refrigeration System

2.1 Use a Refrigeration Compressor with an Economizer

The screw compressor can be infinitely adjusted in the energy range of 20~100% to adapt to the change of load. It is estimated that a screw unit with a cooling capacity of 233kW and an economizer can save 100,000 kW·h of electricity per year based on an annual operation of 4,000 hours.

2.2 Selection of Heat Exchange Equipment

Preferably use evaporative condensers instead of water-cooled shell and tube condensers, which not only saves the power consumption of the water pump, but also saves the investment in cooling towers and water tanks. In addition, the water flow required by the evaporative condenser is only 1/10 of that of the water-cooled condenser, which can save a lot of water resources.

Regarding the evaporator in the cold storage, preferably use an air cooler instead of a tube evaporator, which not only saves materials but also makes the heat exchange efficiency higher. And if a stepless speed-adjustable air cooler is used, the air volume can be changed to adapt to the changes in the load in the warehouse.

When the goods are just put into the warehouse, the air cooler can be run at full speed to quickly reduce the temperature of the goods. After the goods reach the predetermined temperature, the speed can be reduced to avoid power consumption and machine loss caused by frequent start and stop.

2.3 Removal of Impurities in the Heat Exchange Equipment

Air separator: When there is non-condensable gas in the refrigeration system, the discharge temperature increases due to the increase in condensation pressure. According to the data, when air is mixed in the refrigeration system, its partial pressure reaches 0.2MPa, the system power consumption will increase by 18%, and the cooling capacity will decrease by 8%.

Oil separator: The oil film on the inner wall of the evaporator will greatly affect the heat exchange efficiency. When there is a 0.1mm thick oil film in the evaporator tube, in order to maintain the set temperature requirement, the evaporation temperature must drop by 2.5℃, and the power consumption will increase by 11%.

2.4 Removal of Scale in the Water Pipes of the Water-Cooled Condenser

The thermal resistance of scale is higher than that of the tube wall of the heat exchanger, which will affect the heat transfer efficiency and increase the condensation pressure. When the scale on the water pipe wall in the condenser is 1.5mm thick, the condensation temperature will rise by 2.8℃ compared with the original temperature, and the power consumption will increase by 9.7%. In addition, scale will increase the flow resistance of cooling water and increase the energy consumption of the water pump.

Methods for preventing and removing scale: Electronic descalers can be used for anti-scaling, and chemical pickling and mechanical descaling can also be adopted.

3. Evaporator Defrosting

When the thickness of the frost layer is larger than 10㎜, its heat transfer efficiency decreases by more than 30%, which shows that the frost layer has such a great impact on heat transfer. Especially when there is a frost layer on the finned tubes in the air cooler, not only does the thermal resistance increase, but also the air flow resistance increases, and in severe cases, there is even no air blowing out.

Hot gas defrost is preferred instead of electric defrost to reduce power consumption.

4. Other Ways to Save Energy

In addition, ice storage technology (IST) can be used. The ice produced at night can provide some cooling during the day, which can bear part of the load to a certain extent and reduce the power required by the system.