R32 refrigerant training

1.Features of R32:

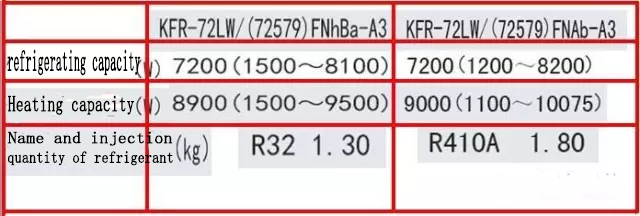

Note: For products using R290 (such as dehumidifiers), if system failures are involved, automatic welding torch repairs are strictly prohibited. Please return the products to the factory according to the process. 1. The global warming coefficient of R32 refrigerant is 1/3 of R410A, which is more environmentally friendly than traditional R410A and R22 refrigerants, but R32 has certain flammability; Relatively environmentally friendly and flammable 2. Compared with R410A refrigerant, the saturation pressure of R32 is about 3% higher, the exhaust temperature is about 8-15℃ higher, the power is about 3-5% higher, and the energy efficiency ratio is about 5% higher; High energy efficiency and high operating pressure 3. Under the same working conditions, the same compressor and the same operating frequency, the cooling capacity of the R32 system is about 5% higher than that of R410A refrigerant. Fast cooling 2. R32 product features Gree has launched T Di, T Pie, Cool King-Ⅱ, and Fresh Air series products using R32 refrigerant in 2015, and will soon launch Q Li, Yue Feng, and T Long series products. 1.The product model is marked with "Nh";

2.Use anti-disassembly nuts on the inner machine side;

3.The perfusion volume of R32 system is 20%-30% less than that of R410A system.

Three, R32 product installation notes

1.The anti-disassembly nut end of the large and small connecting pipe needs to be connected to the indoor unit, and the non-disassembly nut end is connected to the outdoor unit;

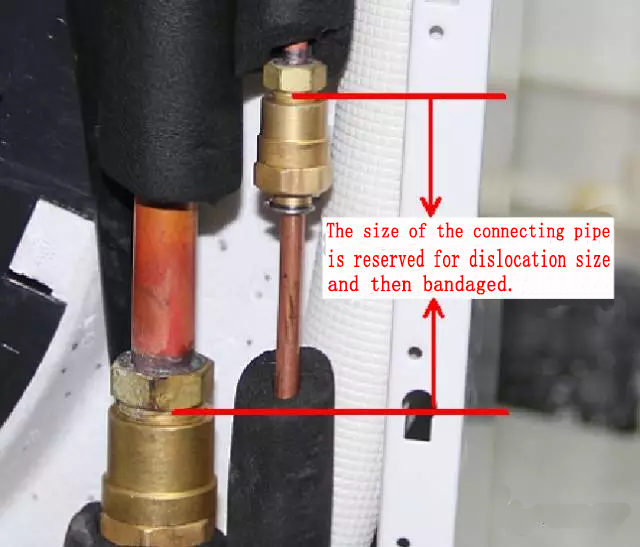

2.Before bandaging the connecting pipe, determine the dislocation size of the anti-disassembly nut end of the connecting pipe according to the dislocation size of the evaporator size joint and then bandage;

3.When connecting the connecting pipe, make sure that the bell mouth is perpendicular to the cone of the evaporator joint, and then tighten the joint;

4.Use two adjustable wrenches to fix at the arrow position, and then take heat preservation measures;

5.Refer to R410A product requirements, vacuum, maintain pressure, open the size of the valve core, and fix the back cover nut;

6.After installation, install the valve protection handle;

7. Other ①.If you need to lengthen the copper pipe, you need to use a thicker copper pipe with a thickness ≥ 8mm;

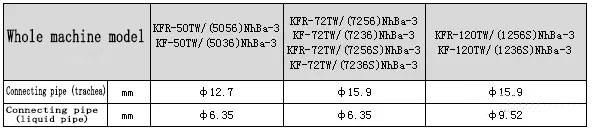

②.If you need to wire in advance for installation, how many wires need to be wired according to the model? (For example, fixed frequency 26 single cooling needs 5 cloths, fixed frequency 26 heating and cooling needs 7 cloths), what pipe diameter is needed? Cannot rely on experience;

Note: Pay attention to the difference of pipe diameter with R22 refrigerant

③. The internal machine and the connecting pipe must be vacuumed and pressure-maintained to ensure that the system is leak-free, and it is not allowed to use the form of emptying instead of vacuuming;

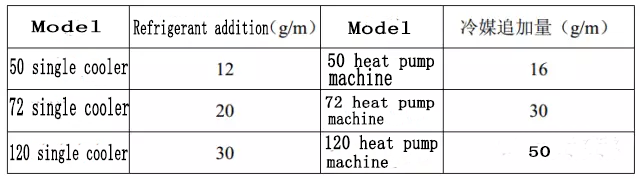

④. For the lengthened copper pipe, it is necessary to add refrigerant according to the situation:

When the connecting pipe is less than or equal to 8m, no additional refrigerant is required. If the connecting pipe exceeds 8m (based on the liquid pipe), additional refrigerant must be added for every 1m over 5m, and an electronic scale must be used for quantitative addition , It is not allowed to add based on feeling or according to parameters such as current and pressure. The additional amount of refrigerant shall be added according to the following standards:

Four, R32 product maintenance precautions

Since the indoor side connecting pipe cannot be disassembled, when the indoor unit system needs to be repaired, the anti-disassembly nut must be destroyed. The operation requirements are as follows:

1. Disassemble the indoor unit

①Recover the refrigerant first, and close the valve cores tightly;

② Use a cutter to cut the connecting pipe 15 mm away from the anti-disassembly nut;

③Because the cutter cannot rotate 360 degrees, you need to shake the connecting pipe left and right by hand to completely disassemble it;

④ After cutting off, dust-proof the connecting pipes, evaporator and evaporator, and then repair the indoor unit;

2. Second installation after maintenance

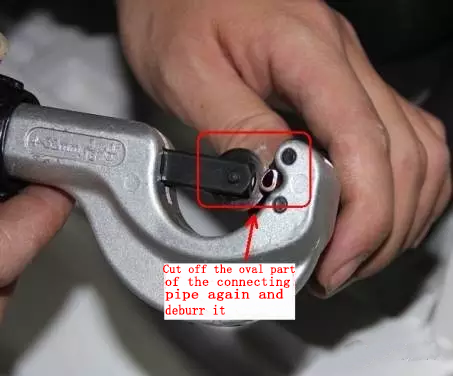

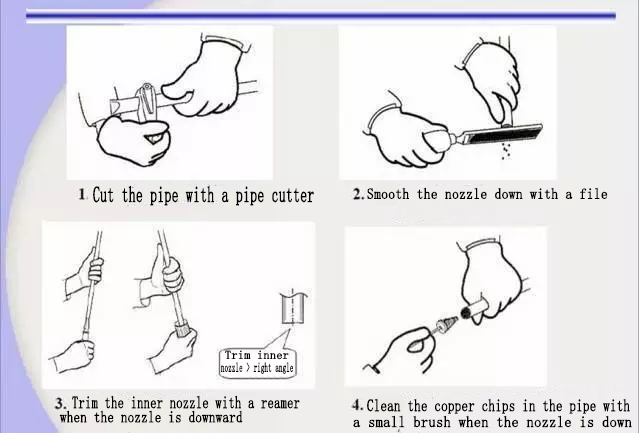

①Reserve the welding size of the anti-disassembly nut fittings, and cut off the irregular oval part;

②Clean up the burr of the bell mouth;

③Welding new anti-disassembly nut fittings on the connecting pipe; (In order to avoid burning the inner machine parts, the inner machine end connecting pipe first welds the anti-disassembly nut, and then penetrates into the machine to connect.)

④ Cut off the evaporator joints, clean up the burrs on the bell mouth, and weld new joint accessories;

⑤The connecting pipe is inserted into the indoor unit and connected, and the connecting pipes are tightened with a wrench;

⑥ Vacuum and maintain pressure;

⑦Open the big and small valve core and tighten the nut of the back cover;

⑧ Install the valve handle.

3. Other

①Welding at the user's house, no combustibles within 2 meters. If a large amount of refrigerant leaks in an unexpected situation, timely ventilation is required, and be careful not to introduce fire sources;

② If the parts need to be replaced in the maintenance of the refrigeration system, the welding operation must be carried out after vacuuming;

③. For the use of hose pliers to remove the "anti-disassembly nut", it is necessary to ensure that there is no damage during the second installation to avoid potential safety hazards.