1. It should be selected according to the calculated value of the mechanical load of each evaporation temperature, and no other equipment should be used.

2. When selecting refrigeration compressors, the cooling capacity of each refrigeration compressor should be matched.

3. There should not be more than two series of refrigeration compressors. If there are only two refrigeration compressors, the same series should be used.

4. The driving power required by the refrigeration compressor should be calculated according to the actual working conditions, and a suitable driving motor should be selected through its manufacturer.

5. The intercooler, gas-liquid separator, oil separator, condenser, liquid receiver, low-pressure liquid receiver, low-pressure circulating liquid receiver, etc. used in the refrigeration system of the cold storage shall be selected through checking calculations and shall be compared with The refrigerating capacity of the refrigerating compressor set in the refrigerating system matches. For large and medium-sized cold storages using ammonia refrigeration systems, no less than two high-pressure ammonia storage devices should be selected.

6. The liquid inlet of the washing type oil separator should be 250mm —— 300mm lower than the liquid outlet pipe of the condenser.

7. The selection of the condenser should meet the requirements. The condensing temperature of the water-cooled type should not exceed 39°C; when the evaporative condenser is used, the condensing temperature should not exceed 36°C. The temperature difference between the inlet and outlet of cooling water in the condenser should be 1.5°C to 3°C for vertical shell and tube condensers; 4°C to 6°C for horizontal shell and tube condensers.For medium and small cold storages that use hydrofluorocarbons and their mixtures as refrigerants, air-cooled condensers should be used.

8. The volume of the liquid discharge bucket in the refrigeration system of the cold storage should be determined according to the room with the largest liquid discharge volume of the evaporator in the cold room of the cold storage. The fullness of the drain bucket should be 70%.

9. The pump for transporting refrigerant should be determined according to the volume flow rate and head of the refrigerant it transports. The cycle multiple of the refrigerant: For evaporators with relatively stable load, fewer evaporator groups, and less oil accumulation, bottom-in and top-out The liquid supply method can be 3 to 4 times; for the evaporator with fluctuating load, large number of evaporator groups, and easy oil accumulation, the liquid supply method can be 5 to 6 times, and the upper inlet and lower outlet The liquid supply method adopts 7 times to 8 times.

At the same time, the pressure at the liquid inlet of the refrigerant pump should have a margin of not less than 0.5m refrigerant liquid column.Under normal circumstances, small-scale cold storage mainly uses fully enclosed compressors. Because the power of the fully enclosed compressor is small, the price is relatively cheap; medium-sized cold storage generally uses semi-hermetic compressors; It is large and can be used for multiple purposes, but the installation and management of cold storage are cumbersome.

When selecting the evaporator, the high-temperature cold storage uses the air cooler as the evaporator, which is characterized by a fast cooling speed, but it is easy to cause moisture loss in the refrigerated product; the medium and low-temperature cold storage mainly uses the evaporation pipe made of seamless steel pipe, and its It is characterized by good constant temperature effect and timely cold storage.

Cold storage maintenance solutions

Freezers refer to facilities that are refrigerated with various equipment and can be artificially controlled and maintained at a stable low temperature. Refrigeration systems, control devices, insulated warehouses, ancillary buildings, etc. are the basic components of cold storage. Cold storage is used for food, medicine, mechanical freezing processing and cold storage. It uses artificial refrigeration to keep the room at a certain low temperature.

The main purpose

Cold storage is mainly used for food, medicine, mechanical freezing processing and cold storage. It uses artificial refrigeration to keep the room at a certain low temperature. The walls, floors and flat roofs of the cold storage building are laid with a certain thickness of heat insulation materials to reduce the heat transfer outside the cold storage. In order to reduce the absorption of solar radiation energy, the surface of the cold storage exterior wall is generally painted white or light color, so the cold storage building is different from the general industrial and civil buildings, and it has its own unique structure.

1. The food industry is used for low-temperature storage and preservation;

2. Low-temperature storage and transportation of biological products in the pharmaceutical industry;

3. The chemical industry is used for cooling and freezing of liquids and air conditioning;

4. Separation, concentration and drying of high-purity gases in the electronics industry;

5. Used in constant temperature incubators for plant seed germination tests in agricultural scientific research units.

STRUCTURE DIAGRAM

Cold storage structure

Refrigeration unit equipment is the most important equipment in cold storage. The refrigeration workflow principle is formed by compressors, coolers, liquid storage tanks, filters, expansion valves, and evaporators.

Installation Precautions

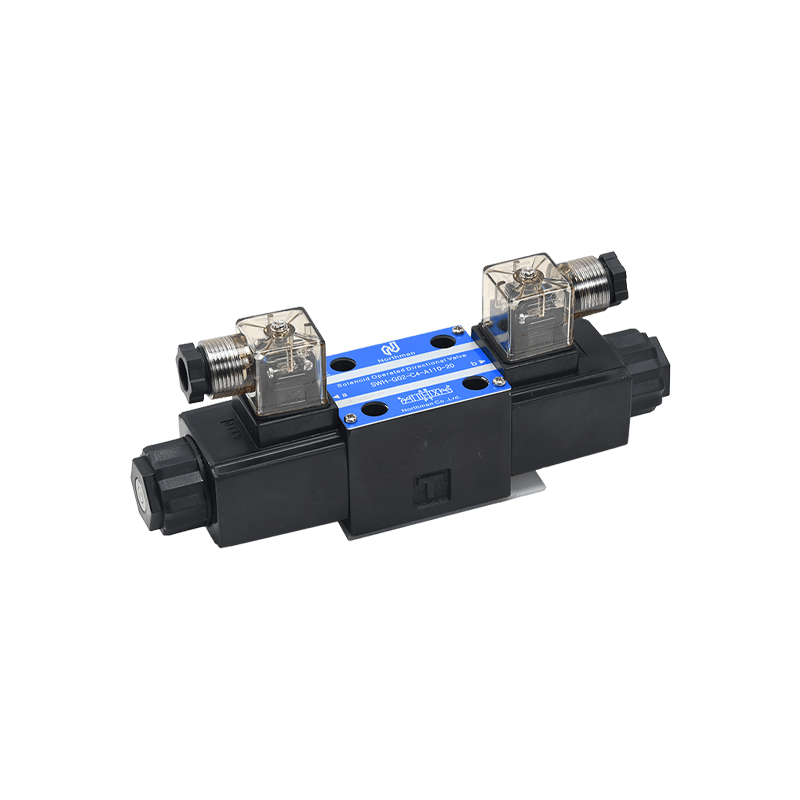

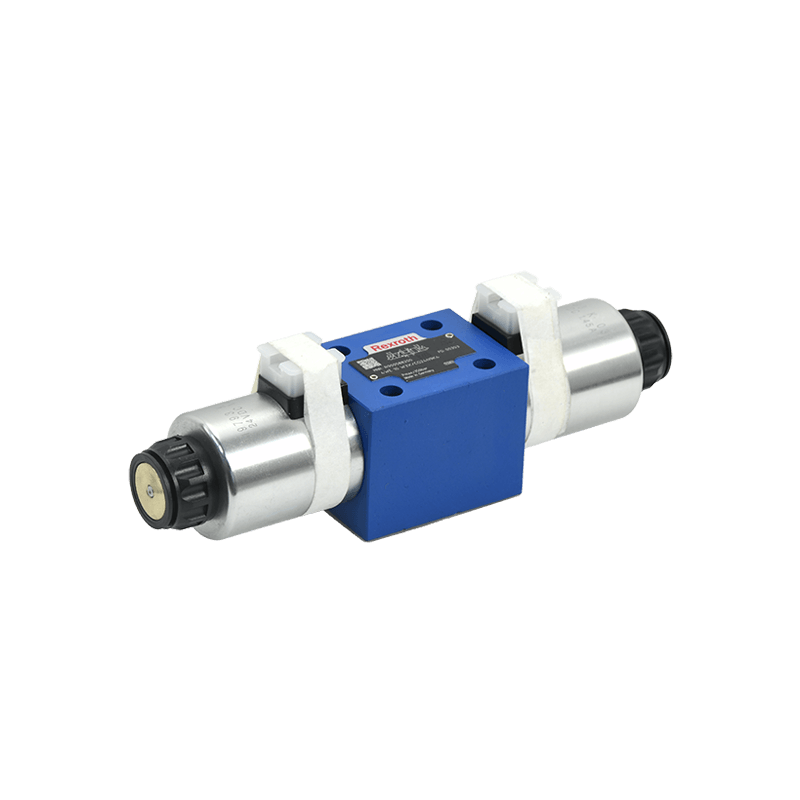

Recommended product

Assembling the equipment needed for cold storage hot items